Fitz Frames’ promise? Custom glasses with 3D printed frames that are easy to order, look great and fit the unique dimensions of the wearer’s face.

When Heidi Hertel founded Fitz Frames five years ago, her mission was “to solve glasses” for kids.

It might not be immediately obvious what that means. After all, anyone who needs corrective lenses would probably agree that when it comes to alleviating vision problems, glasses work.

But take a few steps back, and think about how a pair of glasses gets to a face. Like many other consumer goods, glasses frames come in only a limited number of sizes. The style that fits one face may be too wide or narrow for another. Conventional glasses have frames with metal hinges, a delicate joint where the pair is likely to break. Purchasing new glasses means trying on many pairs of frames, then ordering, waiting maybe several weeks, and then paying a not-insignificant price for them. Buying glasses is hard enough on adults, but even worse for kids. Once a child makes it through this process, he or she is then tasked with taking care of an expensive necessity — only to quickly grow out of the frames and repeat the process all over again.

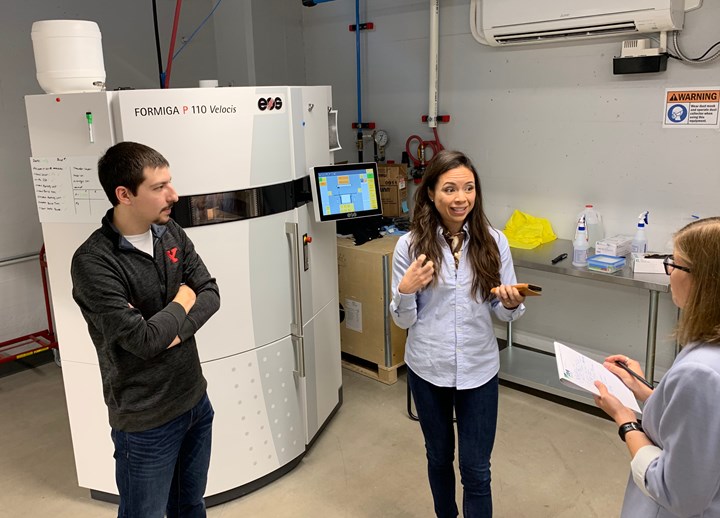

Heidi Hertel, founder, and Gabe Schlumberger, CEO, of Fitz Frames. The company’s mission is to solve the problems with kids’ eyewear: cost, time, fit and durability. Photo Credit: Fitz Frames

Hertel doesn’t wear corrective lenses herself, but has children who do. Seeing the many steps in the process, as well as the price tag for glasses, convinced her that there had to be a better way. The glasses she was buying for her kids took too long to receive, didn’t always fit well, and were liable to break or be outgrown quickly.

The vision for Fitz Frames, then, was to ease the buying experience and make glasses that would be better for kids in terms of fit, style and durability. In other words, Fitz Frames was founded to solve both the process and product of glasses.

The company is already succeeding at this mission. Fitz Frames is now shipping hundreds of custom glasses with 3D printed frames per week from its facility within the Youngstown Business Incubator (YBI) in Ohio. And it all starts with a smartphone app.

Buying 3D Printed Glasses with Augmented Reality

Traditionally, purchasing glasses involves having an eye exam, receiving a prescription, and then picking out and ordering frames at a physical office or store. Once ordered, the glasses may take several weeks to be made and shipped. The process is relatively slow and expensive, and may involve multiple return trips to order and receive a pair of glasses. When a child outgrows the frames, or his or her prescription changes, the process begins again.

Fitz Frames takes a different approach. Instead of visiting a physical storefront, kids and their parents select frames using a compatible iPhone with the Fitz Frames app. Two of the company’s key employees, Gabe Schlumberger, CEO, and Katie Bassett, VP of product and operations, both have past experience at Disney — so it’s perhaps no surprise that the app is based on software used by animators.

Katie Bassett, vice president of product and engineering (pictured) and co-founder Gabe Schlumberger met at Disney, where Bassett used 3D printing for prototyping toys and merchandise. At Fitz Frames, however, this technology is applied for production.

Using the smartphone’s front camera, the app allows for an augmented reality (AR) experience where users can see selected frames superimposed on their own faces, and change the design and color to make a purchase decision. Then, the app asks the user to pose for a series of photos to capture measurements of his or her face. Before checkout, users have the option to add a custom message to the inner right temple, and are prompted to upload a photo of their prescription, input their eye doctor’s contact information or sign up for an email reminder to add prescription information. (The company also offers non-prescription options as well.) Once received, the order is complete and sent to the Youngstown facility for manufacturing. If a user already has a prescription in hand, the entire ordering process can be done in just a few minutes.

Though the front-end experience of this app is smooth and simple, there is a lot happening behind the scenes. This kind of augmented reality buying experience for something three-dimensional like a pair of glasses has only been possible in the last few years, with the latest generation of smartphones. The iPhone 10 and models above this now include the necessary depth capability on the front-facing camera, which is the key that allows Fitz Frames to capture exactly the right measurements for each customer. This data capture is significant because Fitz Frames’ 3D printed glasses frames do not come in standard sizes. Instead, they are literally made to fit, for each and every wearer.

What Dimensions Make a Design?

When designers create conventional glasses frames, they base the size and proportions around one key measurement: the bridge of the nose. Designs often come in just one size, and if the bridge doesn’t fit, neither will the glasses. But with Fitz Frames’ promise to fit any face, and the ability to deliver on this promise via 3D printing, the company found it needed to approach design differently.

“When you can tweak any design in any dimension, it totally changes how you design,” Bassett says. Creating frame designs thus was not as simple as laying out a static geometry. Instead, Fitz Frames had to work with designers to make the frames scalable, by mathematically constraining the frame dimensions that are intrinsic to a given design while allowing other dimensions to vary based on the wearer’s unique measurements. The company currently offers six frame styles, all of which can be adapted to each wearer’s measurements while retaining the core aspects of its design.

In addition to making glasses frames that fit better, Fitz Frames has also innovated on how pairs are assembled. Conventional metal hinges are often a point of failure, so Fitz Frames chose to simplify and reduce the part count for each set of frames using a snap-fit hinge. The company’s frames consist of just three 3D printed pieces: a front piece with rims to hold the lenses, and two temples that attach to the rims with a snap-fit connection. The frames are designed to come apart at this joint rather than break, and can be easily snapped back together.

A snap fit hinge makes Fitz Frames’ glasses easy to assemble, as well as snap back together if the temples become separated.

3D Printing for Glasses on Demand

Improving the buying experience and giving kids access to glasses that fit were top priority for Fitz Frames, but becoming the manufacturer of those glasses initially was not a priority. The company first looked for a partner in the United States that could manufacture frames with the quality, flexibility and scalability the business would require. When that proved to be a challenge, it chose to bring manufacturing in house.

Will Hallewell, AM lead, inspects 3D printed and dyed frames before they go to the lens manufacturer to be completed. A side benefit of Fitz Frames’ snap-fit hinge design is also illustrated in this photo: the ability to mix and match colors by swapping out temples and rims.

While headquarters remains in California, Fitz Frames’ production facility is now established within the YBI, in a space located on the first floor of the former printing facility for The Vindicator, Youngstown’s local newspaper. As of July 2019, Fitz Frames has vertically integrated all of its operations except for lens manufacturing and installation, which happens at a partner’s facility just a few miles away. The two companies are so close geographically that rather than pay for shipping, Fitz Frames simply drives over the 3D printed glasses frames each morning, and returns to retrieve the finished glasses later in the day.

Proximity to this partner is one reason Fitz Frames can manufacture its glasses on demand, but the enabling process is 3D printing. Because every set of frames customized to the wearer, each pair of glasses Fitz Frames produces is essentially a unique product. Without 3D printing, this proposition would be difficult and time consuming to achieve.

“When I first came on board, I was skeptical that 3D printing was the right process,” says Bassett, who has past experience at Pixar using 3D printing as a prototyping technology for toys and merchandise. “This was maybe the first application I had ever seen where 3D printing really made sense for production.”

Once a user completes an order through the app, Fitz Frames receives the measurements and design information, and converts this into an OBJ file that will be delivered to its printers. A unique five-digit identification number is automatically added to each frame and its matching temples at this stage so that each set can be matched together later.

The company has two EOS Formiga P110 Velocis 3D printers that use selective laser sintering (SLS) to fuse powdered polymer — in this case, nylon 12 — into parts. As Bassett notes, the SLS process has the advantage of little warping as well as no need for support structures. Up to 72 parts, or 24 complete frames, can be printed in a batch, customized to the sizes and shapes of wearers’ faces.

Why manufacture in Youngstown? According to Bassett, the city has the right mix of manufacturing history and additive resources. In addition to the YBI, the city is home to America Makes and Youngstown State University, manufacturing engineer Matt Lawson’s alma mater.

Postprocessing Makes It Possible

Fitz Frames is currently printing about one batch of frames per day on each of its 3D printers, but the glasses are far from finished when the frames emerge from the printer.

The surfacing process used at Fitz Frames smooths the rough texture inherent in SLS 3D printing. The Rosler tumblers seen here are just part of the multistage finishing strategy.

Each set of frames goes through several smoothing steps after printing.

“People are used to polished acrylic frames,” Bassett says, “so we had to find a way of finishing the frames to a similar aesthetic.”

After the 3D printed glasses frames are unpacked from the build envelope, they are first put through a bead blaster to remove any excess powder. Then, the frames go through a multistage surfacing process to create the final finish for the glasses.

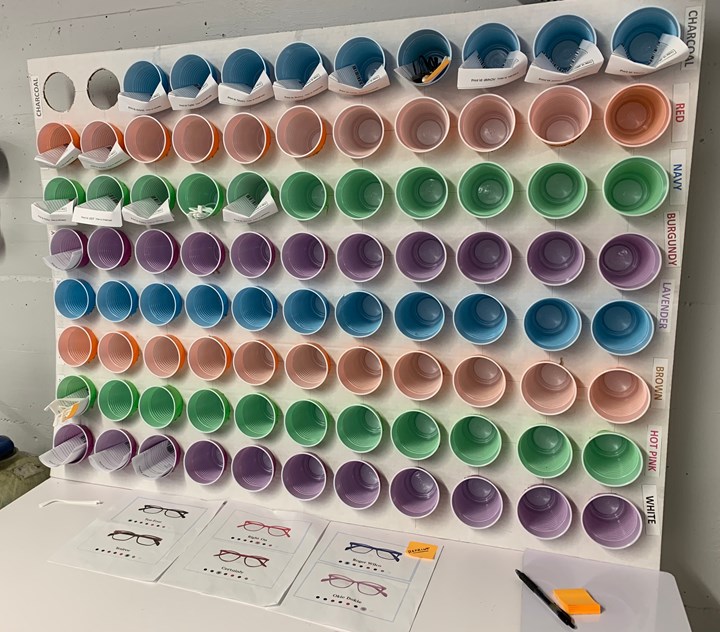

Once the surface finishing is complete, temples and frames are matched into sets again by code and organized based on their final color. When a critical mass of frames for a single color has been collected, those frames will go into a dye tank from DyeMansion. Afterward, they are ready to travel to the lens manufacturer for assembly. Finished glasses return to the YBI facility for packaging and shipping.

Undyed frames are sorted and held until enough pairs of a particular color has been amassed. For now, the workflow solution Fitz Frames has found to track this is colored plastic cups arranged in a poster board by dye color.

Rethinking Glasses

Fitz Frames is delivering custom glasses frames for kids that not only fit better, but are also cheaper and faster than conventional pairs. A complete pair of glasses starts at $95, with the option to add blue light coating for computer work, or upgrade to sunglasses. The time period from completed order to receiving Fitz Frames glasses is currently about 10 days, most of which is spent in postprocessing and shipping. The company is working to shorten that time period even further, down to about a week.

But Fitz Frames isn’t just improving the buying process for a single pair of glasses. Unlike designer styles that are retired after a couple of seasons, Fitz Frames’ designs will be available indefinitely; the source files are simply stored digitally, ready to adapt to any wearer’s face. The app also stores user profiles, so replacing a pair of glasses is as simple as reordering. Customers can even sign up for an annual subscription plan that includes two pairs of glasses and unlimited frames for each calendar year — often a better option for kids than buying a single conventional pair.

During the ordering process, kids can input a message to be printed inside the right temple of the frames. “Don’t give up” appears here next to the identifying code for this pair.

But ultimately, the best benefit that Fitz Frames might bring comes from the personalized buying experience. Kids can choose not only the style of their frames, but also the color and the message on the inner temple. They are not just passive consumers of a finished product, but instead make choices that will affect how those frames will be manufactured.

“When kids are involved in not just picking something out, but actually making them, they are more likely to wear them.”

“When kids are involved in not just picking something out, but actually making them, they are more likely to wear them,” Bassett says. At Fitz Frames, “solving” glasses is not just about manufacturing frames that fit, look and perform better than conventional ones, or delivering them faster and more cheaply. It also means producing glasses that are more likely to be worn.

Related Content

What Does Additive Manufacturing Readiness Look Like?

The promise of distributed manufacturing is alluring, but to get there AM first needs to master scale production. GKN Additive’s Michigan facility illustrates what the journey might look like.

Read MoreWhat is Powder Bed Fusion 3D Printing?

Whether in metal or polymer, with a laser or an electron beam, powder bed fusion (PBF) is one of the most widely used 3D printing techniques.

Read MoreAirless Basketball Shows Promise of 3D Printed Lattices: The Cool Parts Show Bonus

Successfully matching the performance of a standard basketball demonstrates the control possible over the mechanical properties of digital materials.

Read More8 Cool Parts From RAPID+TCT 2022: The Cool Parts Show #46

AM parts for applications from automotive to aircraft to furniture, in materials including ceramic, foam, metal and copper-coated polymer.

Read MoreRead Next

3 Companies That Wouldn't Exist Without 3D Printing

3D printing’s affordability enables the existence of companies that wouldn’t be able to manufacture their products conventionally. Here are just three examples.

Read MoreShoe Insoles Precisely Tailored to Individual Feet: The Cool Parts Show #4

This episode of The Cool Parts Show looks at how 3D printing will deliver tailored products. Scanning feet for their geometry and pressure enables Aetrex and EOS to manufacture insoles that are unique to individual wearers.

Read More3D Printed Custom Glasses: The Cool Parts Show #8

Fitz Frames has reimagined glasses, from the frames to the ordering process. See how the company manufactures glasses customized to every face in this episode of The Cool Parts Show.

Read More

.jpg;width=70;height=70;mode=crop)