7 Important Implications of the New Stratasys Production Demonstrators

One working machine concept expands the build size and speed for FDM. Another performs robotic 3D printing in composite material. Here is what these two concepts suggest about the advance of additive manufacturing into industrial production.

Share

Read Next

Stratasys recently unveiled two working concepts for production-oriented 3D printing at its Minneapolis-area U.S. headquarters. Both systems will be seen at the International Manufacturing Technology Show (IMTS) in September.

One is a robotic composites demonstrator. A system employing a Kuka robot and a pivoting rotary table achieves eight axes of precisely controlled motion to generate lightweight, rugged production parts from carbon-fiber-filled plastic material.

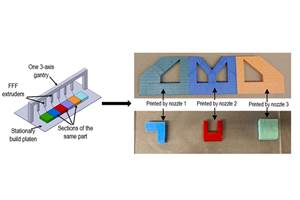

The other is the company’s so-called “Infinite Build” demonstrator for large 3D parts. Applying 3D printing in a horizontal configuration (not vertical) enables the machine to build parts up to 40 by 30 inches in cross section, with the Z “height” limited only by the floor space the eventual user of such a machine might devote to accommodating it. A platen that is upright like a wall receives the first layer of the part, then backs farther and farther from the deposition head with each new layer until the build is done. A likely application for this machine is large tooling, and Boeing and Ford Motor Company partnered in the development of the machine with tooling applications in mind.

Because the builds are big, fast extruders are also an important part of the infinite-build concept. The extruder on the current machine achieves 10× material deposition speed over the company’s current commercially available fused deposition modeling (FDM) technology, while another extruder design is in development that will achieve 100×.

Significantly, both of these machines—the robotic composites machine and the large-part horizontal printer—are indeed demonstrators, the company says. Neither machine concept is final yet, let alone available for sale. The hope in showing these systems at IMTS is to prompt feedback that might lead to significant further refinement before some later versions of these machines are brought to market.

I recently watched the machines in action at a media event the company hosted, at which Stratasys officials and representatives of their partner companies offered perspectives on the promise of 3D printing for industrial production. I came away with several observations about the two machine concepts, and what they illustrate and signify.

Here are some thoughts:

1. Production AM will transcend traditional 3D printer design.

Perhaps the most obvious conclusion from observing the production demonstrators is this: Getting to the most efficient and effective 3D printer design for a given industrial production application might mean thinking outside the box—literally.

The traditional 3D printer is a box-shaped machine building parts in vertical layers. That machine has long been sufficient for making one-offs and prototypes, and machines based on this same model are already established in industrial production. Yet the needs of some production applications might demand capabilities beyond what this box can attain. The infinite-build demonstrator tips this box on its side to significantly extend the potential Z travel of the machine. And the robotic composites demonstrator essentially abandons that box, layering material onto the part in various directions and in various orientations within a single build.

2. The advance into production means differentiation by industry.

Rich Garrity, Stratasys’s president for the Americas, speaks of a “customer-use-case-driven” model that increasingly drives the company’s technology development. When the goal is efficient production via AM, the aim has to be not on making printers per se, but instead on understanding and addressing the “pain points” that additive manufacturing can potentially address, which differ by industry. The result will inevitably be diverse 3D printers performing in diverse ways and offering different capabilities for different industries’ requirements.

In fact, the printer itself won’t always be the answer to the pain point, Garrity says. Stratasys is also a software company. Further development of its recently acquired digital manufacturing hub GrabCAD will improve the ability to manage and initiate 3D printing production jobs. And the company is also a contract manufacturer, able to provide part production services through its Statasys Direct division for companies transitioning into additive production.

3. The impediments to AM are not permanent; they are being overcome.

In the comments she made at the event, Teri Finchamp, director of operations and quality for Boeing Phantom Works, listed some of the challenges her company has long faced related to adopting 3D printing within production. The list she gave consisted of build size limitations; learning to design for AM; and certifying 3D-printed parts for use in aircraft.

Dr. Ellen Lee, technical leader of additive manufacturing research for Ford, offered a list of her own. The challenges she cited were: build speed limitations; assuring the performance of 3D-printed parts; and the limited range of materials available for AM.

The two lists overlap. Size and speed are related concerns, since limited speed is part of what makes large builds impractical. And Boeing’s concern about certification is essentially the same as Ford’s concern about assuring performance—the core of the challenge in either case is validating that a part can do what it must, and that the process will reliably produce parts that meet this condition across the production run. Therefore, the combined list of impediments to production AM could be expressed this way:

- Limitations on build size and speed

- Assurance of part performance

- Learning to design for AM

- Limited range of materials

All of us who are involved with AM are familiar with this list. This set of concerns, along with perhaps one or two others, has become easy to recite when discussing the state of AM technology today. But here is the thing: As illustrated by the infinite-build demonstrator, the challenge in the first bullet is drawing near to being solved. In this case, it took a high-deposition-rate extruder coupled with a horizontal approach to that deposition that opens up the potential work volume. Meanwhile, very large additive machines already in use from other AM technology companies offer their own solutions as well. Soon, the day will come when we no longer place build size on our list of impediments.

Our aim with Additive Manufacturing magazine and this website has been to remain focused on realistic coverage of the capabilities of additive manufacturing, including taking care to give due attention to its shortcomings and its limitations. However, the shortcomings won’t always be there. Part of being realistic is also to recognize the progress that engineers are making, and to prepare for the day when the limitations have been removed.

4. Automation is essential to industrial AM.

The composites demonstrator has a robot. It achieves most of the eight axes of motion by moving and pivoting the deposition head.

The infinite-build machine also has a robot. On this machine, the robot does not directly apply the material, but instead loads new material when a canister runs out. The robot could also change the machine’s heads so that the machine could print with different materials during the same build. Thus, the robot on this machine largely waits instead of printing, but its role is just as vital. Even with fast deposition, the continuous operation of a production 3D printer is liable to be long, meaning automation to keep the machine producing will be an essential part of the process.

Indeed, the robot is likely to be only the most visible facet of this. Also essential will be the in-situ automation in the form of systems that respond to subtle changes in temperature and material flow by minutely adjusting parameters to keep the process consistent. In machines making prototypes and even low volumes, this consistency over time is not necessarily a concern, but in full production, it becomes a crucial requirement for success.

5. AM is fundamentally a digital thread technology.

Control technology company Siemens was a partner on the development of the robotic composites demonstrator, and for more reasons than just the precise motion control. Just as importantly, programming of the robotic system is performed within the NX environment from Siemens PLM. This integrated suite of software products provides for an integrated set of possibilities surrounding this 3D printing system.

For example, immediately after printing, the robot could change heads to equip itself for CNC machining, performing drilling and finish milling on the recently 3D-printed part in order to complete it. NX could program this material removal as well. The robot could then change to a scanning head in order to validate the part by comparing its final dimensions to the CAD model—the very same model created originally within the same software suite.

This kind of seamlessness in the digital life of the part is not possible within more typical part processing. Conventional manufacturing typically involves steps that break the so-called “digital thread,” the ideal of a single data set for a part that defines every aspect of its production. If the part is metal, for example, then its processing may involve forging or casting, a step performed in a facility that is both physically and digitally separate. From there, it likely goes on to manual setups on machine tools, and it might be inspected in part through manual gaging.

By comparison, if that metal part was replaced by a composite part grown in something like the robotic composites machine, then the scenario could be much different. Here, the part could be modeled, made, machined and measured all within a single environment...with the data for all of these steps entirely captured within a single, comprehensive digital record guiding and expressing everything about the part’s production. Additive manufacturing and digital manufacturing are in fact so closely related that we might eventually come to regard each one as a logical extension of the other.

6. Directionality of deposition is an engineering variable.

The composites demonstrator machine builds with polymer material containing chopped carbon fiber. One goal for the further development of the machine is to implement a continuous-fiber system, and in this way control the directionality of individual fibers during the part’s build. In a significant way, however, the machine is already achieving influence over structural properties through a different kind of directional control: control of the deposition path.

Traditional 3D printers have this control only in a limited way. The X-Y path is programmable, but the Z value is fixed at each layer, resulting in a part with horizontal strata. In general, 3D printers are really 2½D machines. But the eight axes of the composites demonstrator permit sufficient freedom of motion for material deposition along any X-Y-Z path.

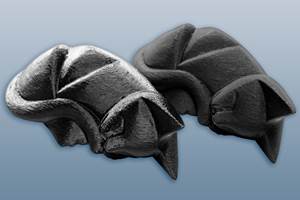

The Stratasys robotic composites demonstrator builds a feature onto the part by layering material at a right angle to layers created earlier in the same build. In a conventional 3D printer this would be unthinkable. Building this way establishes the directionality of deposition as a new engineering variable for designing strength into the part.

This freedom essentially creates a new variable for engineering strength into the part. The component produced on a machine such as this no longer has to have the equivalent of a “grain” resulting from Z layering. Rather, where Z layers do occur, additional deposition at some different orientation of the part can span these layers to deliver strength in a perpendicular direction.

The composite demo part made on this machine illustrates this. The core of the dome-shaped part was grown in a continuous helix as the rotary table spun, resulting in Z-axis layers. But then, within the same build, the table tilts the part to grow reinforcing fins across the existing layers at right angles to the previous build. This manipulation of layering direction would be unthinkable on a conventional 3D printer. On this machine, it enabled the build of a composite dome just one bead of material thick, but strong nevertheless because of the fin reinforcement.

7. The interconnection with other facets of advanced manufacturing means this is not just an AM advance.

The role of robots in making discrete parts is frequently limited to part handling. Robots are not capable of the kind of precise, high-force motion necessary for heavy machining, for example.

Yet in the composites demonstrator, the robot’s role expands. It becomes a direct part-making device, and because the potential machining needs are so light, it could even finish the part completely.

Similarly, carbon-fiber-reinforced composite material is generally limited to lower-volume production. Composite parts often involve manual lay-up, not scalable to large production runs of parts.

Yet in the composites demonstrator, here is an entirely automated process for making an intricate composite part. The removal of the requirement for hand labor results in process that could indeed be applied to production volumes.

Those observations suggest what I find to be the most striking aspect of the demonstrator machines, the composite machine in particular. Namely: This is not just an additive advance. I saw the composite machine in a 3D printing context as presented by a 3D printing company. But if I had seen this in a robotics context, it could have been presented as an advance for manufacturing with robots. If I had seen it in a composites context, it could have been presented as an advance for composites as well.

The question is still sometimes asked: Will additive take the place of conventional manufacturing technologies? For some parts and in some applications, the answer is yes. But as this Stratasys machine concept demonstrates, the larger and longer-term answer to the question might be very nearly the opposite. As additive increasingly integrates with conventional technologies, it will actually extend what those existing technologies can do.

Related Content

PostProcess’ FDM Support Removal Reduces Postprocessing Time

The company says the Vorsa 500 reduces support removal processing times in additive manufacturing by over 50%.

Read MoreUnusual Forms of 3D Printing, and How to Categorize This Technology: AM Radio #21A

In this episode of AM Radio, Stephanie Hendrixson and Peter Zelinski quiz each other on six 3D printing processes — some common, some novel. Test your own knowledge and stick around for a discussion about how to categorize (or maybe re-categorize) AM technologies.

Read MoreInsight Masterbatches Reduce Gloss, Improve Appearance of PLA, PETG FDM Systems

Insight Polymers’ low gloss masterbatches for PLA and PETG FDM systems improve the appearance of a 3D printed part by imparting a matte finish and mitigating layer lines with minimal impact on mechanical properties.

Read MoreRutgers Engineers Create Faster, More Precise 3D Printing Process

Researchers says their Multiplexed Fused Filament Fabrication Process could be a game changer for the 3D printing industry.

Read MoreRead Next

Hybrid Additive Manufacturing Machine Tools Continue to Make Gains (Includes Video)

The hybrid machine tool is an idea that continues to advance. Two important developments of recent years expand the possibilities for this platform.

Read More4 Ways the Education and Training Challenge Is Different for Additive Manufacturing

The advance of additive manufacturing means we need more professionals educated in AM technology.

Read MoreAt General Atomics, Do Unmanned Aerial Systems Reveal the Future of Aircraft Manufacturing?

The maker of the Predator and SkyGuardian remote aircraft can implement additive manufacturing more rapidly and widely than the makers of other types of planes. The role of 3D printing in current and future UAS components hints at how far AM can go to save cost and time in aircraft production and design.

Read More