6 Innovations From the Additive Manufacturing Pavilion at IMTS 2022

The explosion of innovative technology at the AM Pavilion at IMTS 2022 is a sign of things to come. No doubt AM will play an important part in the interdisciplinary future of the manufacturing technology industry.

Share

IMTS 2022 was buzzing with excitement over the newest AM innovations — from hybrid technologies to specialty applications and new printing methods. One thing is clear: AM is empowering manufacturers to imagine new possibilities for their customers, leading to more opportunities in specialty markets.

“AM technology exists today for us to be manufacturing lot size one. It is no longer mass production. It is mass customization,” says Barbara Humpton, president and CEO for Siemens Corp., at the IMTS+ Main Stage.

The Additive Manufacturing Pavilion at IMTS 2022 featured 110 additive manufacturing exhibitors covering more than 100,000 square feet of floor space. These companies demonstrated a comprehensive range of new AM hardware, software and materials. Here are just a few advanced AM technology companies that piqued a lot of interest at the show.

1. Flexible additive/subtractive/inspection hybrid systems

Hybrid Manufacturing Technologies offers additive, subtractive and inspection solutions as a single OEM hybrid solution through more than 10 machine tool manufacturers. This combined approach provides a system that’s more flexible and uses a smaller footprint than separate, dedicated machines for high-mix, low-volume part needs. Plus, multiple hybrid systems enable for line balancing to increase production responsiveness and reduce processing bottlenecks. The integrated capability, which includes laser-based directed energy deposition (DED) and/or polymer extrusion additive processes, is best suited for finishing or repairing high-value parts.

2. Print with high-viscosity resins for parts with expanded functionality

Fortify uses a process called Digital Composite Manufacturing (DCM), which prints high-viscosity composite resins with aligned reinforcing fibers. The company has taken one of the most prevalent 3D printing processes — vat photopolymerization (VP) — and expanded upon the concept to make functional parts with variable thermal, electrical and mechanical properties. Applications for parts produced with DCM range from injection mold soft tooling to high-performance thermal, electrostatic discharge and radio frequency components.

3. Low-heat metal bonding

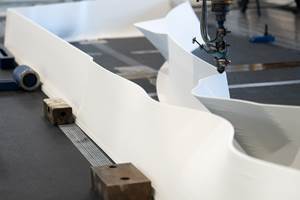

Fabrisonic has developed and offers hybrid sheet lamination (SL) equipment, leveraging the company’s ultrasonic additive manufacturing (UAM) process integrated with machining capabilities. The company’s metal SL solutions use ultrasonic vibration with minimal heat to bond materials. This low-temperature process enables Fabrisonic to bond different metals that are otherwise difficult to combine using traditional methods. The technology has found notable success in electric vehicle, space and defense applications.

4. Lower cost laser printing for small companies

Xact Metal has introduced laser powder bed fusion (LPBF) printers at a lower price point than others, making AM accessible to smaller companies. Thanks to simpler laser technology in its smaller models, the mid-five-figure price range is a fraction of traditional LPBF systems that start in the low- to mid-six figures. Xact Metal has demonstrated the importance of price and value when adopting a new AM process for the first time. Its LPBF systems are best suited for prototyping and mold/tool development.

5. Closed-loop printing for tight specifications, soft polymer parts

Inkbit is a material jetting (MJ) technology developer that offers materials, hardware and software for its vision-controlled jetting process. Based on technology similar to household 2D inkjet printers and combined with UV light, Inkbit’s process cures individual layers before being inspected by the machine vision system. The process incorporates a closed feedback loop that compares individual layer heights to the part design and can adjust deposition in subsequent layers to better meet part specifications. Inkbit specializes in soft polymer parts for use as seals, grippers and skin contact applications.

6. Fast printing for high-precision, production-grade tools

Mantle has developed a process that combines CNC machining with metal paste extrusion specifically designed for tooling insert applications. The company’s technology makes high-precision, production-grade tools in a faster time frame than traditional approaches can make them today. Mantle represents a trend toward companies finely tuning their AM technology to meet the needs of specific applications.

The explosion of innovative technology at the AM Pavilion at IMTS 2022 is a sign of things to come. No doubt AM will play an important part in the interdisciplinary future of the manufacturing technology industry.

More AM Events to Come

AMT and Gardner Business Media have collaborated with Mesago (the organizers of Formnext) and Messe Frankfurt Inc. to launch:

- Formnext Forum Austin - Aug. 28-30, 2023 – More at FormnextForum.com

- Formnext Forum - Sept. 9-14, 2024 (co-located at IMTS 2024 in Chicago)

- Formnext Chicago - April 8-10, 2025

Related Content

3 Points About 3D Printing Large Parts We Can Learn From the Lunar Habitat (Video)

Ingersoll Machine Tools describes the capabilities and promise of large-scale additive manufacturing as seen in the 3D printed sections of the Rosenberg Space Habitat.

Read MoreShotless Cavitation Water Jet Peening Technology

IMTS 2022: Sugino’s shotless water jet peening is well suited for medical devices that need the benefits of shot peening without the contamination of traditional peening media.

Read MoreHybrid Manufacturing Turns Design Inside Out

Hybrid systems combine traditional subtractive processes with additional processes, including laser metal deposition for additive manufacturing and friction stir welding, enabling manufacturers to design products from the inside-out.

Read MoreFast Wire EDM Machines Remove 3D-Printed Metal Parts From Large Build Plates

IMTS 2022: EDM Network’s mid-sized, four-axis Fast Wire EDM machine is said to provide three to four times faster cutting power.

Read MoreRead Next

Hybrid Additive Manufacturing Machine Tools Continue to Make Gains (Includes Video)

The hybrid machine tool is an idea that continues to advance. Two important developments of recent years expand the possibilities for this platform.

Read More3D Printing Brings Sustainability, Accessibility to Glass Manufacturing

Australian startup Maple Glass Printing has developed a process for extruding glass into artwork, lab implements and architectural elements. Along the way, the company has also found more efficient ways of recycling this material.

Read MoreAt General Atomics, Do Unmanned Aerial Systems Reveal the Future of Aircraft Manufacturing?

The maker of the Predator and SkyGuardian remote aircraft can implement additive manufacturing more rapidly and widely than the makers of other types of planes. The role of 3D printing in current and future UAS components hints at how far AM can go to save cost and time in aircraft production and design.

Read More