Foam components provide cushioning and protection in many applications, including sports equipment, protective gear and footwear. But foam eventually breaks down, and it can be difficult to customize. 3D printed lattice structures provide a replacement option for foam components that can last longer and be customized to fit the user. On the latest episode of AM Radio, cohost Stephanie Hendrixson and I discuss applications where 3D printed lattice structures are replacing foams. Listen above, or read on for the transcript and notes.

Transcript

Julia Hider

Welcome to AM Radio, the show where we tune into what’s happening in additive manufacturing. On this episode, Stephanie Hendrixson and I will discuss why replacing foam with 3D printed lattices is a home run. Then as 2021 comes to a close we’ll count down our top 10 articles of the year. That’s all coming up on AM Radio.

Stephanie Hendrixson

This episode of The AM Radio podcast is brought to you by PTXPO, the show for North American plastics professionals. Join Additive Manufacturing Media and sister brand Plastics Technology for the first ever edition of this event in May of 2021. Find more information at PlasticsTechnologyExpo.com.

Julia Hider

Welcome to AM Radio. I’m Julia Hider. And I have my fellow editor Stephanie Hendrixson with me in the studio today.

Stephanie Hendrixson

Hi Julia.

Julia Hider

Alright, Stephanie, how do you feel about baseball?

Stephanie Hendrixson

I like the atmosphere at a baseball game. Like, I like going to the stadium, I like seeing the game. I don’t really care about teams or winning or…

Julia Hider

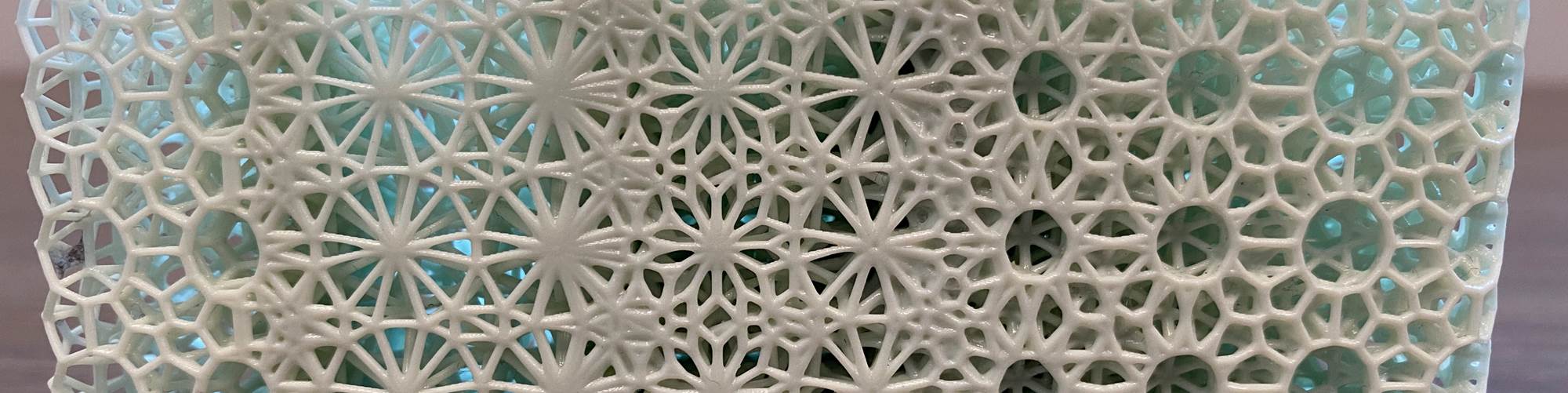

I agree with you. That’s why it’s boring to watch baseball on TV, in my opinion. But the reason I’m asking you is because just the other day we published this article I wrote about Rowling’s new baseball glove, which is called the REV1X. And they have 3D printed inserts that were manufactured by Fast Radius using Carbon DLS technology. And these inserts are replacing what used to be inserts made out of foam. But the problem with the foam is that you have to break it in and then it eventually degrades and breaks down. So between the break in and the break down, Rawlings wanted to find a way to extend the lifecycle of these inserts so that the gloves field was more consistent. So they eventually landed on 3D printed lattice inserts made from flexible polyurethane, and Rawlings use Carbon’s design engine to help automate the design of these lattices, which are pretty complex, because the thickness level varies to help the glove conform to the player’s hand and improve ball control. And as I was talking to John Nanry, he’s the cofounder and chief manufacturing officer at Fast Radius. He said that the company is in development on some other sporting good and protective gear applications for 3D printing that would be replacing foam. So I was wondering if you have any examples of this also?

Stephanie Hendrixson

I do. But first off, that is just really cool. Like, the whole thing of breaking in a baseball glove, I guess I’m sort of, like, tangentially aware of all the weird things people do to try and like get the glove flexible enough and all those things. And so taking the foam out and replacing them with these 3D printed lattices is not just like a comfort thing or like a functional thing. It’s like actually a time savings thing because you’re not having to, like, break the glove into your exact hand.

Julia Hider

Exactly. And I never really thought about how the foam breaking down made it feel inconsistent. So that, yeah, that was interesting to talk about as well.

Stephanie Hendrixson

So I guess thinking about other examples that I’ve seen, you mentioned, they’re looking at other types of sporting equipment. So there’s this company in the UK that I learned about a couple years ago that makes custom bike helmets. You have to put on, like, this skullcap scan your head, and they have to get the exact shape of your skull. But then they 3D print this padding, and it looks like honeycomb. So, the company’s name is HEXR. H-E-X-R.

Julia Hider

Very start up name.

Stephanie Hendrixson

Yeah, yeah, very startup name. And so they print this liner. That’s exactly the shape of your head, kind of similar to the baseball glove. They say that this lattice design has better padding from different directions than just your typical foam helmet. The other kind of funny side effect about it is that because it’s this honeycomb — and like you can see it if you if you look inside the helmet — you can see what it looks like, is airflow. If you’ve ever spent a couple hours in a bike helmet, it gets kind of hot and sweaty in there. And like this honeycomb provides the same cushioning that the foam does actually maybe better cushioning than the foam does. But it’s also, like, helping the bike riders stay cool and not overheat while they’re riding.

Julia Hider

Yeah, that makes a lot of sense. They’re like vents in the helmet. I’m looking at a picture of it right now. And there are these vents in the helmet that allowed the honeycomb to peek through. So yeah, I could definitely see that being cooler. I don’t really know of any other companies that are making custom bike helmets in any way, 3D printing or anything else. And that makes a lot of sense. The whole mass customization angle of it.

Stephanie Hendrixson

Yeah for sure, another big application that I’ve seen that we haven’t talked about yet is footwear, lots of foam goes into shoes, a lot of layers of material that are needed to pad your foot in some way. We’ve seen a couple of examples of that. So there was an episode of The Cool Parts Show that, that just recently came out where we featured Hilos, which is the company that makes the custom heels and it’s a sustainability story because there are only two materials you can take them apart and break them down and recycle them at the end of their lifespan. One of those pieces is the platform of the shoe, so they’ve kind of combined the heel and the outsole and the midsole and insole. There’s like this lattice on the inside that is providing the cushioning to your foot, so it’s enclosed. It’s not something that you can see, but you can kind of feel it through the bottom of the foot bed.

Julia Hider

Have you tried the shoes on, Stephanie?

Stephanie Hendrixson

I have tried the shoes on. I will say they are not really for me. But those heels are really, they’re, they’re, they’re very stable. And even though you can sort of feel the lattice, like it doesn’t feel uncomfortable or anything — like that it is very flexible, very comfortable.

Julia Hider

Nice. Do you have any applications in mind when it comes to, like, more athletic shoes instead of fashion shoes? Because, you know, when I think of foam and shoes, I just think of how a pair of running shoes wears out. And then I get shin splints or something. So there has to be applications for athletic shoes, right?

Stephanie Hendrixson

Yeah, one that comes right to mind is actually not a complete shoe, but the insole. So there’s this company called Aetrex that makes custom insoles. They are a full footwear company — they do lots of different things. And they, they make conventional custom inserts as well. But now they have a line of 3D printed ones where you get your foot scanned, and based on the shape of your foot, the size of your foot, they can print this insole. But it’s actually like a little bit more complicated than that. Like so far, I think we’ve mostly been talking about lattices where it’s kind of consistent throughout the whole printed piece. And what they do is actually vary the lattice, vary the shape of the cells, the size of the struts, like all that kind of stuff based on the pressure map of your foot. So we did an episode of The Cool Parts Show on this. Both Pete and I got our feet scanned. And it was really funny because when you flip over the insole and look at these different lattices, you can see how the pattern changes across your foot. And like for me, my feet are kind of slightly two different sizes and, like, the pressure map was different. And so when you looked at the different lattices, the pattern change, they were not symmetrical, they were not the same from foot to foot. I think that that’s kind of an interesting illustration of, like, why replacing foam with lattices is so interesting and potentially beneficial, because you can actually change the behavior of the material.

So on that note, like changing the material properties across a lattice structure, something else that comes to mind is this summer, I was able to go visit Lubrizol. They’re located in, kind of, the Cleveland area. And they’re a company that makes all different types of TPU, all different types of thermoplastic polyurethane, and one of the things that they talked about while I was there is this product called VarioShore TPU. It’s a joint product that was developed by Lubrizol and this other company ColorFabb. And it’s, it’s a filament for 3D printing. And what’s so neat about it is that it is an active foaming material. So depending on the temperature that you use in your printer, like at the nozzle, this material can actually foam. It can get to up to 1.6 times its original volume. So if you printed like above a certain temperature, you can get that, that foaming quality. And as the material foams as it spreads out like that, it gets softer, it gets more flexible. And so within the same part, within the same print without actually varying your lattice geometry if you don’t want to, you can adjust the material properties just by changing the temperature of the material that you’re printing add.

Julia Hider

That sounds really cool. And like I wish, you know, there was like a picture, video of it or something because it just sounds like it would be really satisfying to watch. But like what are the applications for that kind of material?

Stephanie Hendrixson

So they’re doing some interesting things with footwear. There’s a company using this material to make specialized shoes for diabetics. They’re doing things like prosthetic liners with it. One of the other applications that I saw was customized grips for crutches, you know, something that we think of is just like you get these standardized crutches with the standard foam handles could actually be customized to your hand into your grip.

Julia Hider

And then yeah, I mean, grips on crutches, but there are lots of other things that have grips that could be customized as well. So yeah, I can see a lot of applications for that.

Stephanie Hendrixson

And if you do want to see what this looks like, I kind of poked around and I found a video from CNC Kitchen on YouTube all about this foaming ColorFabb filament, so you can look that up, and actually, there’s some, there’s some cool footage of the filament coming out of the nozzle, and it doesn’t look smooth like you would expect, like it’s kind of like spiky like you can see it starting to expand.

Julia Hider

Alright, I’m definitely gonna check that out because I think it sounds like it would be really cool to watch. I think that’s a good place to wrap up this segment.

Related Content

10 Important Developments in Additive Manufacturing Seen at Formnext 2022 (Includes Video)

The leading trade show dedicated to the advance of industrial 3D printing returned to the scale and energy not seen since before the pandemic. More ceramics, fewer supports structures and finding opportunities in wavelengths — these are just some of the AM advances notable at the show this year.

Read MoreHow Siemens Energy Applies Additive Manufacturing for Power Generation and More

At an applications center in Orlando, Florida, a small team of AM specialists is spanning industries by 3D printing parts to support both Siemens Energy power generation systems and external customers.

Read MoreHow Norsk Titanium Is Scaling Up AM Production — and Employment — in New York State

New opportunities for part production via the company’s forging-like additive process are coming from the aerospace industry as well as a different sector, the semiconductor industry.

Read MoreAluminum Gets Its Own Additive Manufacturing Process

Alloy Enterprises’ selective diffusion bonding process is specifically designed for high throughput production of aluminum parts, enabling additive manufacturing to compete with casting.

Read MoreRead Next

The Foot Measurement System That Allows for Mass Customized Insoles

Aetrex’s Albert scanner is an example of how advances in measurement technology aid 3D printing in realizing its promise.

Read More3D Printed Baseball Mitt Inserts Are Ready for the Big Leagues

Fast Radius was able to use Carbon’s DLS system for both prototyping and production of 3D printed, fatigue-resistant inserts for Rawlings’ REV1X baseball glove.

Read MoreCustom Heels Are a Step Up for Circular Fashion, Sustainable Manufacturing

Custom shoe company Hilos demonstrates how, with additive manufacturing, relative outsiders can not only launch a product, but implement a new production mindset into an established industry. The company is bringing comfort and customization to fashion footwear with sustainable, on-demand production based on 3D printing.

Read More