Rawlings’ new REV1X baseball glove contains a number of innovations, including the addition of 3D printed thumb and pinky inserts. Fast Radius used Carbon’s DLS technology for both prototyping and production of the inserts.

Baseball is an American tradition, and although the game has changed over the years, the baseball glove has stayed much the same. Rawlings’ new REV1X outwardly carries on the design of the traditional baseball glove, but it contains a number of hidden innovations, including the addition of 3D printed thumb and pinky inserts. In order to develop and manufacture these inserts, the company needed to find partners it could work with from the design and prototyping stages all the way up to full-scale production.

Traditional baseball mitts contain thumb and pinky inserts that are made out of foam. This foam requires a break-in period, and then it eventually degrades over time. Between the break-in period and the breakdown of the inserts, the gloves’ performance can be inconsistent, so Rawlings wanted to create inserts with a different lifecycle. This way, the feel and performance of the glove would be more predictable.

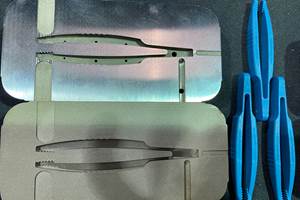

To replace the foam, Rawlings turned to Carbon to design 3D printed latticed inserts out of flexible polyurethane. Carbon in turn connected Rawlings with cloud-based manufacturer Fast Radius to produce the inserts. As the largest Carbon Production Network partner in North America, Fast Radius had the expertise and infrastructure to manage the project from prototyping to production. “We have a strong track record of bringing elastomeric lattice structure type applications to market and supporting them,” explains John Nanry, co-founder and chief manufacturing officer at Fast Radius. “Carbon introduced us as a production expert on lattices, and we then partnered closely with Rawlings through their product development cycle and scaling to production.”

The 3D printed inserts were designed to replace traditional foam inserts, which wear out over time. By designing a longer-lasting insert, Rawlings hopes to produce a glove that has a more predictable, consistent feel.

According to Nanry, Carbon’s Digital Light Synthesis system is a good fit for this application for three reasons:

- Scalability. Nanry says that the platform’s speed and setup make it ideal for quickly scaling up to production. “It’s very easy to go from one part to ten parts to a hundred to thousands,” he explains.

- Materials. The inserts required a material that was shock-absorbing and resistant to fatigue but still flexible. Carbon’s FPU 50 had the right combination of flexibility to enable players to catch and handle the ball, and fatigue resistance to withstand the impact of baseballs that could be travelling over 100 miles per hour without breaking down, Nanry says.

- Cost. Nanry adds that, from a total cost perspective, this mode of production is competitive. While it is difficult to make a cost comparison because the inserts can’t be made using an alternative process, Nanry says that Fast Radius “likes these applications” — where the value of the 3D printed part to the customer is significantly higher than the cost to make it.

The inserts have lattices with varying thickness levels to conform to the player’s hand and improve ball control. They were designed using Carbon’s Design Engine, with manufacturability input from Fast Radius.

Design

Rawlings designed the inserts using Carbon’s Design Engine, which automates lattice creation. The final design includes lattices with varying thickness levels to conform to the player’s hand and improve ball control. At this stage, Fast Radius worked with the company to provide feedback on manufacturability and produce initial inserts for prototype gloves. Rawlings sent these gloves to players in the spring of 2020 to test and provide feedback. “There were several revisions,” Nanry says. “That’s the beauty of additive. You can revise and iterate so quickly at very low cost.”

Once all of the revisions were made, Fast Radius created a build package, where it locks all of the build parameters so the process is repeatable and can be scaled to production. The whole design process, from the time Fast Radius first got involved to the point where it had a locked build package for the inserts, took about three months.

Production

Nanry says Fast Radius’s biggest challenge in scaling up production of the inserts was establishing repeatability in post-processing operations. First, the inserts need to be washed to remove excess resin. “What’s unique about this part is the lattice density and [the challenge of] being able to wash that in a consistent way,” he explains.

Once washed, the inserts are baked. However, the company found that the parts were prone to curling up during the process, which Nanry refers to as a “potato chip effect.” In order to counter this, the company designed custom jigs and fixtures to keep the inserts flat during the baking process.

With a locked build package and scalable processes in place, Fast Radius was able to expand production. Although the company was unable to share current production rates, Nanry says that production could eventually grow into the tens of thousands.

Nanry says that this project illustrates the potential of AM for existing products. “What’s exciting to me about this application is that it really shows how additive can lead to a radical redesign to something that’s as classic and stable as an American baseball mitt,” he says. “It just shows the extent that companies that really embrace it can innovate.... The potential out there is just so huge.”

Watch: Sports Helmets Use 3D Printed Lattice Instead of Foam

“Digital materials” resulting from engineered flexible polymer structures made through additive manufacturing are tunable to the application and can be tailored to the head of the wearer. WATCH

Related Content

How to Build 10,000+ Shot Molds in Hours

Rapid tooling isn’t so rapid when it takes days to 3D print a metal mold, and then you still must machine it to reach the necessary tolerances. With Nexa3D’s polymer process you can print a mold in hours that is prototype or production ready and can last for more than 10,000 shots.

Read MoreFoundry Lab: How Casting in a Day Will Improve the Design of Metal Parts (Includes Video)

The company’s digital casting process uses 3D printing, but the result is a cast part. By providing a casting faster than a foundry, the company says effective prototyping is now possible for cast parts, as well as bridge production.

Read MoreAdditive Manufacturing's Evolving Role at Fathom Now Emphasizing Bridge Production

Bridge production is currently the biggest opportunity for additive manufacturing, says Fathom Manufacturing co-founder Rich Stump. How this service provider leverages AM while finding balance with other production capabilities.

Read More3D Printing Enables Mold Shop to Rapidly Prototype Medical Parts (Video)

A case study involving Mantle’s 3D printing technology allowed moldmaker Westminster Tool to go from design to injection molded prototype medical parts in three weeks.

Read MoreRead Next

AM 101: Digital Light Synthesis (DLS)

Digital Light Synthesis (DLS) is the name for Carbon's resin-based 3D printing process. How it works and how it differs from stereolithography.

Read More3D Printing for Production at Ford: The Cool Parts Show #7

The parking brake bracket on the Mustang Shelby GT500 is now 3D printed instead of stamped. Learn how Ford is thinking about additive manufacturing in this episode of The Cool Parts Show.

Read MoreCarbon, Lamborghini 3D Print Auto Parts at Scale

Carbon and Lamborghini have partnered to use Carbon’s DLS technology for part production.

Read More