Wayland Additive’s Calibur3 for Stress-Free Metal Parts

Rapid + TCT 2022: The system features the NeuBeam hot part process rather than a hot bed process, which means it can efficiently create parts that are free of residual stresses because the high temperatures are only applied to the part and not the bed.

Share

Read Next

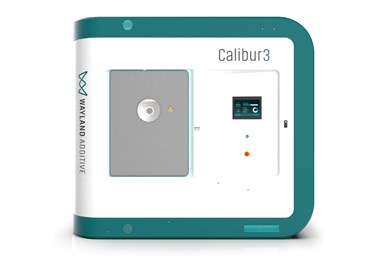

Wayland Additive’s Caliber3 metal 3D printer. Photo Credit: Wayland Additive

Wayland Additive’s Calibur3 metal additive manufacturing (AM) system which features the NeuBeam process is said to introduce a step-change in performance and capability from other metal AM machines. The company says the NeuBeam process is an entirely new, groundbreaking powder bed fusion (PBF) process that offers the opportunity to 3D print metal parts that cannot otherwise be produced due to current metal AM process limitations.

It is said the potential for new applications is greatly increased because NeuBeam offers the opportunity to use a much wider range of metal materials. It also enables the production of larger parts without having to worry about residual stress or gas cross flow and without having to pre-sinter the powder bed, the company says. The printable area of the first version of the Calibur3 system is 300 × 300 × 450 mm.

NeuBeam is a hot part process rather than a hot bed process. According to the company, this means it efficiently creates parts that are free of residual stresses because the high temperatures are only applied to the part and not the bed, ensuring free-flowing powder postbuild (no sinter cake) and stress-free parts with reduced energy consumption. In addition, the process is said to overcome many of the limitations for manufacturing large components — no residual thermal stresses, no gas cross flow and a much simplified powder removal process than existing eBeam systems.

The company says the process is capable of producing fully dense parts in a wide range of materials, many of which are not compatible with traditional eBeam or laser PBF processes, such as refractory metals and highly reflective alloys. As a result, the process is said to demonstrate vastly improved metallurgy, without many of the compromises that existing metal AM processes necessitate.

Related Content

-

Postprocessing Steps and Costs for Metal 3D Printing

When your metal part is done 3D printing, you just pull it out of the machine and start using it, right? Not exactly.

-

Additive Manufacturing Is Subtractive, Too: How CNC Machining Integrates With AM (Includes Video)

For Keselowski Advanced Manufacturing, succeeding with laser powder bed fusion as a production process means developing a machine shop that is responsive to, and moves at the pacing of, metal 3D printing.

-

3D Printed Cold Plate for an Electric Race Car: The Cool Parts Show #51

An unconventional lattice design and biomimicry are key to the performance of this fluid-cooled heat exchanger for a battery-powered race car.