Hybrid Software’s CloudFlow Maker Automates 3D Printing Workflow

Formnext 2023: CloudFlow Maker is a modular production workflow suite for file processing, asset management, soft proofing and workflow automation.

Share

Read Next

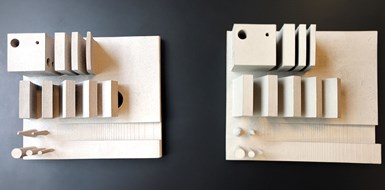

An AISI 316L and 17-4 PH specimen for the evaluation of new functionalities in CloudFlow Maker. Photo Credit: Hybrid Software

Hybrid Software’s CloudFlow Maker is an enterprise workflow solution for industrial-scale binder and material jetting. The software was developed specifically for additive manufacturing (AM) technologies, providing printer producers and users with an exceptional tool to prepare and execute their prints.

It is a modular production workflow suite for file processing, asset management, soft proofing and workflow automation. It is also a web-based application platform specifically tailored for packaging graphics with support for PDF, color separation, trapping, screening, proofing and more.

The company says CloudFlow Maker is a truly industrial solution. Built on OPC-UA standards, the software ensures interaction with all connected devices and machines. And, as the software is fully API-based, it offers smooth connections with all other systems — acknowledging the reality that one-solution-for-everything is nonexistent.

Yet real-world connectivity isn’t the only reason to consider talking to Hybrid Software, according to Kris Binon, AM Business Unit development manager. “Having decades of experience in jetting the right drop on the right spot is just one thing. Industrial printing software is about the ability to provide fast, secure and modular solutions, as well as customer-oriented support, maintenance and upgrades.”

To raise the bar from a technical perspective, Hybrid Software can rely on two other sources. First, parent organization Hybrid Software Group boasts the world’s major provider of printhead electronics for binder jetting: Meteor Inkjet. Combining its hardware with Hybrid’s own software guarantees a direct, secure data stream from CAD up to printhead. Meteor’s expertise on drop formation, binder delivery systems, waveforms and more is unique in the 3Dprint industry, and CloudFlow Maker complements the existing offerings from Meteor Inkjet and its partners.

Also, Hybrid Software’s experienced engineering team has 12-plus years of successful product development for industrial printing applications such labels and packaging to bring to bear for CloudFlow Maker.

“The 3D printing industry is at a crossroads. As printer producers and users turn toward industrialization, they need software to optimize and streamline their workflows for high-volume production,” says Mike Rottenborn, CEO of Hybrid Software Group. “To achieve this, Hybrid is leveraging our expertise in enterprise workflow for printing to develop value-adding functionalities for binder and material jetting.”

- Learn more about binder jetting in our AM 101 section. Binder jetting requires no support structures, is accurate and repeatable, and is said to eliminate dimensional distortion problems common in some high-heat 3D technologies. Here is a look at how binder jetting works and its benefits for additive manufacturing.

- Learn more about material jetting in this article by Tim Simpson, professor of engineering design & manufacturing at Pennsylvania State University. Recent advances in materials processing capabilities have renewed interest in material jetting, the additive process that allows 3D objects to be built by placing different combinations of material drop-by-drop.

Related Content

10 Important Developments in Additive Manufacturing Seen at Formnext 2022 (Includes Video)

The leading trade show dedicated to the advance of industrial 3D printing returned to the scale and energy not seen since before the pandemic. More ceramics, fewer supports structures and finding opportunities in wavelengths — these are just some of the AM advances notable at the show this year.

Read MoreHow 3D Printing Will Change Composites Manufacturing

A Q&A with the editor-in-chief of CompositesWorld explores tooling, continuous fiber, hybrid processes, and the opportunities for smaller and more intricate composite parts.

Read MoreHow AM Enables Cobot Automation for Thyssenkrupp Bilstein (Includes Video)

The shock absorber maker has responded to its staffing shortages through extensive use of collaborative robots. In-house 3D printing makes this possible by providing the related hardware needed to complete the cobot-automated cells.

Read More500-Pound Replacement Part 3D Printed by Robot: The Cool Parts Show #50

Our biggest metal cool part so far: Wire arc additive manufacturing delivers a replacement (and upgrade) for a critical bearing housing on a large piece of industrial machinery.

Read MoreRead Next

4 Ways the Education and Training Challenge Is Different for Additive Manufacturing

The advance of additive manufacturing means we need more professionals educated in AM technology.

Read MoreHybrid Additive Manufacturing Machine Tools Continue to Make Gains (Includes Video)

The hybrid machine tool is an idea that continues to advance. Two important developments of recent years expand the possibilities for this platform.

Read MoreAt General Atomics, Do Unmanned Aerial Systems Reveal the Future of Aircraft Manufacturing?

The maker of the Predator and SkyGuardian remote aircraft can implement additive manufacturing more rapidly and widely than the makers of other types of planes. The role of 3D printing in current and future UAS components hints at how far AM can go to save cost and time in aircraft production and design.

Read More