Henkel Expands Loctite Range of Photopolymer Resins

Formnext 2023: The company provides a wide range of high-performance engineering-grade resins specifically designed for industrial applications, rapid prototyping to end-part production.

Henkel has expanded its portfolio of photopolymer resins for 3D Printing with four Loctite materials, offering performance and versatility. From rapid prototyping to end-part production, these products are designed to support a diverse range of applications.

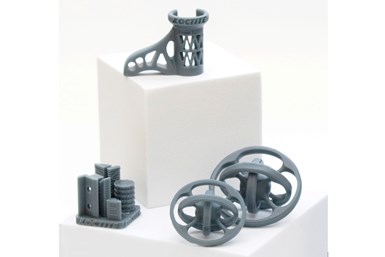

The tough, industrial photopolymer resins include unique high impact-resistant 3D printing materials for durable, functional and production parts. The specialized resins are characterized by distinct and unique properties tailored to specific industrial or commercial applications.

Loctite 3D PRO9274 is a durable dark gray resin that enables fast printing of highly detailed parts. Designed to seamlessly print on various types of digital light processing (DLP)/liquid crystal display (LCD) printers, the material enables users to produce a broad range of products all at a cost-effective price point.

Loctite 3D IND3380 is a specialty resin with electrostatic dissipative (ESD) properties and a high heat deflection temperature (HDT) of 190°C that offers excellent stiffness, precision and versatility.

Loctite 3D IND5714 is a gray elastomer resin with high rebound properties and excellent repetitive strain resistance. A low shore hardness combined with excellent compression set, good tear resistance and strength makes this material well suited for use in industrial elastomeric, safe touch applications.

Loctite 3D MED9851 is a high-performance medical material with excellent tensile and flexural physical properties. Stiffness combined with toughness and its transparent appearance make this material well suited for an extensive variety of impact-resistant medical device applications.

“We are excited to introduce these additions to our product lineup,” says Dr. Daniel Adams, vice president at Henkel Loctite 3D Printing. “The new products represent an extension of every one of our product lines and thereby enable our customers to manufacture parts for an even wider range of industries, applications and use cases.”

The company provides a wide range of high-performance engineering-grade resins specifically designed for industrial applications. Designed for various DLP and LCD platforms, Loctite resins have the mechanical properties to support aerospace, automotive and transportation, industrial and manufacturing, medical and consumer goods applications. The Loctite line can support additive manufacturing at a production scale with a broad material portfolio, including properties such as high-impact, high-temperature resistance and even elastomeric.

- Read about Nexa3D working with material experts at BASF and Henkel to validate custom formulations for its ultrafast fleet of industrial and desktop 3D printers. Nexa3D expanded its resin portfolio with ceramic, flexible, clear materials.

- Learn about Henkel validating Loctite formulations on a Desktop Metal Xtreme 8K Machine. The workflow validations are said to provide complete specifications for printing, curing and cleaning parts printed with Loctite materials.

Related Content

Formnext 2022: Ceramics, Robots and Other Perspectives From Near and Far: AM Radio #30

The 2022 edition of Formnext revealed more options and applications for 3D printed ceramics, anticipation of coming automation, established companies entering AM and more. Two editors — one present at the show, and one observing from a distance — compare notes in this episode of AM Radio.

Read More10 Video Reports From Formnext 2023

Our Formnext video playlist: Stephanie Hendrixson and Peter Zelinski report on various technologies seen at Formnext 2023 in brief videos they filmed at the show.

Read MoreFormnext Chicago Secures Premier Exhibitors for 2025 Event

Companies include some of the premier providers of additive manufacturing technologies as well as startup companies launching new materials solutions, capturing the entire spectrum of AM-related technologies.

Read MoreCopper, New Metal Printing Processes, Upgrades Based on Software and More from Formnext 2023: AM Radio #46

Formnext 2023 showed that additive manufacturing may be maturing, but it is certainly not stagnant. In this episode, we dive into observations around technology enhancements, new processes and materials, robots, sustainability and more trends from the show.

Read MoreRead Next

4 Ways the Education and Training Challenge Is Different for Additive Manufacturing

The advance of additive manufacturing means we need more professionals educated in AM technology.

Read More3D Printing Brings Sustainability, Accessibility to Glass Manufacturing

Australian startup Maple Glass Printing has developed a process for extruding glass into artwork, lab implements and architectural elements. Along the way, the company has also found more efficient ways of recycling this material.

Read MoreHybrid Additive Manufacturing Machine Tools Continue to Make Gains (Includes Video)

The hybrid machine tool is an idea that continues to advance. Two important developments of recent years expand the possibilities for this platform.

Read More