Elementum 3D’s High-Strength Aluminum Alloy Eliminates Need for Heat Treatment

Elementum 3D’s A5083-RAM5 aluminum alloy enables manufacturers to print advanced components from a high-strength aluminum alloy with reduced postprocessing time and cost.

Elementum 3D’s A5083-RAM5 aluminum alloy material was developed in part with the support of the U.S. Army to provide exceptional printability, highly consistent properties and impressive strength, all without requiring heat treatment.

Traditionally, wrought aluminum alloy 5083 has been known for its high strength and corrosion resistance, making it a top choice for applications in seawater and other harsh environments. However, its composition has historically made it unsuitable for use in fusion-based additive manufacturing (AM) processes due to solidification cracking.

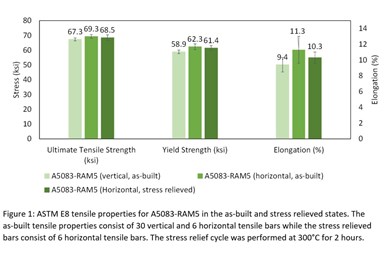

Utilizing patented reactive additive manufacturing (RAM) technology, these limitations have been overcome by synthesizing nanoscale reinforcements during the printing process to create a fine equiaxed microstructure with superior properties and printability, the company says. As a result, A5083-RAM5 exhibits consistent tensile properties in both horizontal and vertical orientations, as well as in as-printed and stress-relieved states.

The RAM additions result in significantly higher strengths than wrought 5083 products, with as-printed A5083-RAM5 demonstrating an impressive 1.8 times the yield strength of strain-hardened wrought 5083-H116 and, in the stress-relieved state, delivering a 2.9 times the yield strength of wrought 5083-O.

The release of A5083-RAM5 enables manufacturers to print advanced components from a high-strength aluminum alloy with reduced postprocessing time and cost. Moreover, the alloy does not contain any rare elements, which can facilitate a robust supply chain.

Printed A5083-RAM5 is designed for use in any applications in which wrought 5083 alloy is traditionally used, including pressure vessels, marine components, aerospace components and energy sector applications, as well as applications that benefit from the higher strength and design complexity offered by A5083-RAM and AM processing.

This research was funded in part by the U.S. Army Research office (ARO). This product is based in part upon work supported by the U.S. Army Small Business Innovation Research Program Office and the Army Research Office under Contract No. W911NF20C0012.

- Listen to this episode of The Cool Parts Show to hear how Masten Space Systems developed a lightweight, reusable rocket engine for NASA’s aim to fly repeated trips to the moon in rapid sequence with little delay between launches. The “Broadsword” engine was made using laser powder bed fusion by Elementum3D on a machine from EOS.

- Read our piece on “Material Innovation Is a Powerful Freedom of AM: Here Are Examples” which mentions the work Elementum 3D is doing to pioneers new metal possibilities for laser powder bed fusion (LPBF), particularly EOS’ platform.

- Learn about Elementum 3D’s collaboration with SLM Solutions on metal powder development, offering a unified approach to enable more powder choices for additive manufacturing users.

Related Content

-

Additive Manufacturing Is Subtractive, Too: How CNC Machining Integrates With AM (Includes Video)

For Keselowski Advanced Manufacturing, succeeding with laser powder bed fusion as a production process means developing a machine shop that is responsive to, and moves at the pacing of, metal 3D printing.

-

Drones Take Flight with Metal and Polymer 3D Printed Parts: The Cool Parts Show Bonus

Drones produced by Cobra Aero now incorporate many 3D printed parts made through laser powder bed fusion and Multi Jet Fusion processes.

-

Aircraft Ducts 3D Printed in Composite Instead of Metal: The Cool Parts Show #68

Eaton’s new reinforced PEKK, tailored to aircraft applications, provides a cheaper and faster way to make ducts compared to formed aluminum.