Carbon-Fiber Reinforced PEEK filament for Long-Term 3D Printed Medical Implants

Evonik’s VESTAKEEP carbon-fiber reinforced PEEK filament offers a balance of high strength, ductility and low weight making it a suitable metal-free alternative for implants.

Share

Read Next

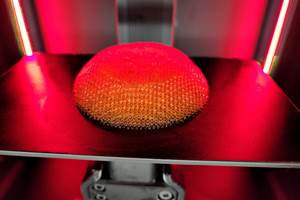

The VESTAKEEP iC4612 3DF and VESTAKEEP iC4620 3DF materials are the two available filaments featuring 12% and 20% carbon fiber content, respectively. Photo Credit: Evonik

Evonik has developed two variations of a carbon-fiber reinforced PEEK filament for use in 3D printed medical implants. This smart biomaterial can be processed in common extrusion-based 3D printing technologies such as fused filament fabrication (FFF) and fused deposition modeling (FDM).

The VESTAKEEP iC4612 3DF and VESTAKEEP iC4620 3DF materials are the two available filaments featuring 12% and 20% carbon fiber content, respectively. The two grades offer a choice of material depending on the required strength and flex properties of 3D printed implants such as bone plates and other reconstructive prostheses.

The two materials offer a variety benefits, including strength from the high carbon-fiber content, matched with the ductility of its PEEK component. Additional benefits include the ability to define the alignment of the carbon fibers during the 3D printing process, high biocompatibility for metal allergy-patients, and no X-rays artifacts.

“By introducing the world’s first carbon-fiber reinforced PEEK filament for long-term medical implants, we continue to design biomaterials that open up new possibilities in today’s medical technology for patient-specific treatment,” says Marc Knebel, head of Medical Systems at Evonik. “As passionate experts with decades of experience in polymer chemistry, we combine a unique set of competencies in materials science, manufacturing technologies and regulatory expertise to customers to accelerate time-to-market of new medical technologies for people's lives beyond limits.”

With a diameter of 1.75 mm, VESTAKEEP iC4612 3DF and VESTAKEEP iC4620 3DF are supplied on 500-g and 1,000-g spools that can be used directly in standard FFF/FDM 3D printers for PEEK materials. The filament is subjected to strict quality management for medical materials.

“No other application field showcases more the advantages of 3D printing, such as individualization or design freedom, than medical technology,” says Knebel. “In trauma applications, for instance, 3D printed solutions offer an enormous time advantage over traditionally manufactured medical devices. It is conceivable that patient-specific solutions can be manufactured within two or three days, significantly improving the recovery phase.”

Over the last five years, Evonik has been gradually developing new PEEK-based filaments for medical 3D printing applications. The current portfolio includes different grades for long-term and short-term body contact applications:

Long-term body contact applications:

- VESTAKEEP i4 3DF - Implant grade (long-term)

- VESTAKEEP i4 3DF-T - Test and development grade

- VESTAKEEP iC4800 3DF - Osteoconductive implant grade

- VESTAKEEP iC4612 3DF – Carbon-fiber reinforced (12%) implant grade

- VESTAKEEP iC4620 3DF – Carbon-fiber reinforced (20%) implant grade

Short-term body contact applications:

- VESTAKEEP Care M40 3DF - Medical care grade

- Learn more about Evonik’s material offerings with the addition of three INFINAM photopolymers to its product portfolio. These photoresin products are for use in common UV-curing 3D printing processes such as stereolithography (SLA) or Digital Light Processing (DLP).

- Read about Evonik’s collaboration with Farsoon on the INFINAM Thermoplastic Copolyester. INFINAM TPC (thermoplastic copolyester) is a ready-to-use, elastomer-grade material for powder bed fusion 3D printing that can enable customers to unlock new markets and applications.

Related Content

Stratasys, CollPlant Unite Technologies for Industrial-Scale Bioprinting of Tissues, Organs

The joint development and commercialization agreement will initially focus on development of a bioprinting solution for CollPlant’s regenerative breast implants, addressing $2.6 billion market opportunity.

Read MoreUnderstanding PEKK and PEEK for 3D Printing: The Cool Parts Show Bonus

Both materials offer properties desirable for medical implants, among other applications. In this bonus episode, hear more from Oxford Performance Materials and Curiteva about how these companies are applying PEKK and PEEK, respectively.

Read MoreGE Additive, Orchid Collaborate on 3D Printing Orthopedic Joint Implants

The agreement bolsters the use of additive manufacturing in the medical implants sector with the development of electron beam melting solutions.

Read MoreDMG MORI: Build Plate “Pucks” Cut Postprocessing Time by 80%

For spinal implants and other small 3D printed parts made through laser powder bed fusion, separate clampable units resting within the build plate provide for easy transfer to a CNC lathe.

Read MoreRead Next

4 Ways the Education and Training Challenge Is Different for Additive Manufacturing

The advance of additive manufacturing means we need more professionals educated in AM technology.

Read MoreHybrid Additive Manufacturing Machine Tools Continue to Make Gains (Includes Video)

The hybrid machine tool is an idea that continues to advance. Two important developments of recent years expand the possibilities for this platform.

Read MoreAt General Atomics, Do Unmanned Aerial Systems Reveal the Future of Aircraft Manufacturing?

The maker of the Predator and SkyGuardian remote aircraft can implement additive manufacturing more rapidly and widely than the makers of other types of planes. The role of 3D printing in current and future UAS components hints at how far AM can go to save cost and time in aircraft production and design.

Read More