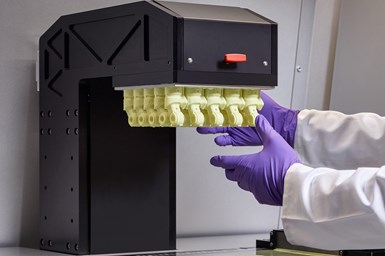

Admatec’s Larger Integrated Binding/Sintering Furnace for Ceramic 3D Printing

Company scales up for more efficient mass customization and serial ceramics 3D printing production lines.

Share

Photo Credit: Admatec

Admatec’s latest integrated debinding and sintering furnace features an enlarged inner volume to offer increased throughput and efficiency for technical ceramic 3D printing and postprocessing. This complements the enlarged printing volume of the Admaflex300 and is designed to foster upscaling to mass production.

The larger version builds on the success of Admatec’s a compact integrated debinding and sintering furnace, which is specially designed for postprocessing of 3D printed technical ceramics. This furnace is said to enable safe, controlled debinding and accurate sintering with good temperature uniformity. With a volume of 180 × 180 × 200 mm and maximum temperature of 1700°C, it is said this furnace is a cost-effective, efficient solution to debind and sinter small parts printed in oxide ceramics.

After enlarging the printing build volume of the Admaflex machines to 260 × 220 × 500 mm in order to upscale to mass production, this larger integrated debinding and sintering furnace is a natural next step with an inner volume of 400 × 400 × 400 mm.

With a maximum temperature of 1,700°C and inner volume of 64 L, the new furnace has almost 10 times the size of the compact integrated furnace, dramatically increasing the throughput and efficiency in technical ceramic 3D printing and postprocessing, the company says.

The company says all these improvements, in combination with specially designed integrated debinding and sintering furnaces, enables users to produce a set of 3D printed technical ceramic parts — from CAD design till sintered end-use part — in less than 7 days.

Related Content

-

10 Important Developments in Additive Manufacturing Seen at Formnext 2022 (Includes Video)

The leading trade show dedicated to the advance of industrial 3D printing returned to the scale and energy not seen since before the pandemic. More ceramics, fewer supports structures and finding opportunities in wavelengths — these are just some of the AM advances notable at the show this year.

-

VulcanForms Is Forging a New Model for Large-Scale Production (and It's More Than 3D Printing)

The MIT spinout leverages proprietary high-power laser powder bed fusion alongside machining in the context of digitized, cost-effective and “maniacally focused” production.

-

New Electric Dirt Bike Is Designed for Molding, but Produced Through 3D Printing (Includes Video)

Cobra Moto’s new all-electric youth motocross bike could not wait for mold tooling. Parts have been designed so they can be molded eventually, but to get the bike to market, the production method now is additive manufacturing.