Omni-Pac, HP Join Forces to Transform Molded Fiber Production, Reduce CO2 Emissions

The companies say this pioneering collaboration will drive digital transformation and sustainability in the packaging industry.

Share

Read Next

Omni-Pac Group, a molded fiber packaging provider, has partnered with HP to digitize and transform the way molded fiber is produced at an industrial level. This collaboration is helping Omni-Pac reduce CO2 emissions and replace single-use plastics with more sustainable packaging solutions. By working together, both companies are aiming to drive innovation and sustainability in the molded fiber industry.

Pablo Libreros, CEO of Omni-Pac Group, expressed his excitement, emphasizing the company’s leading role in driving innovation and sustainability within the industry through its collaboration with HP. “Our collaboration with HP allows us to revolutionize the production of molded fiber at an industrial scale, transforming the development, launch and production of molded fiber applications,” Libreros says. “This not only reduces environmental impact but also pioneers sustainable packaging solutions.”

Libreros also highlighted the significant benefits of the collaboration. “Enabling us to achieve over 500 tons per machine per year through digitalization, the level of CO2 savings will continue to improve as our collaboration with HP progresses,” he adds.

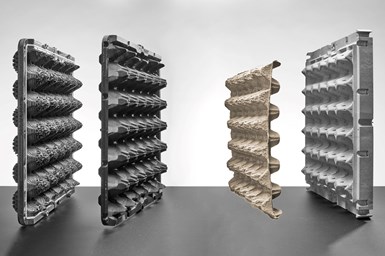

HP’s Molded Fiber Tooling Solution provides a customized digital solution for companies like Omni-Pac, enabling them to achieve unprecedented levels of efficiency and sustainability. The adoption of HP’s technology empowers Omni-Pac to deliver innovative products that meet the evolving needs of consumers and businesses. The solution includes the HP Molded Fiber Advanced Tooling technology, which optimizes manufacturing processes, delivering high-quality products with enhanced performance through Computational Fluid Dynamics (CFD) grammage control and customized features such as logos and textures.

Additionally, it significantly enhances Molded Fiber packaging sustainability by reducing the carbon footprint during tooling and part production, resulting in lighter parts with equal or better performance.

Mariona Company, global head of fiber-based sustainable packaging at HP, notes the significance of the collaboration. “HP's Molded Fiber Tooling Solution technology is empowering companies like Omni-Pac to deliver efficiencies, enable new products, and reduce CO2 emissions,” Company says. “By working together, Omni-Pac and HP are at the forefront of driving innovation and sustainability in the molded fiber industry.”

HP says its ambition is to be a lighthouse brand for purpose. By 2030, the company intends to become the world’s most sustainable and just technology company. With a shared vision and common goals, Omni-Pac and HP are united in their commitment to creating a better future. This collaboration is said to serve as a testament to the power of innovation, driving the industry toward a more sustainable and environmentally conscious approach to packaging production.

- Read about growing additive manufacturing adoption with HP aiming for the C-Suite. 3D printing has been largely the purview of service bureaus and technical specialists, but HP sees a future where it is increasingly the concern of OEM executives — and the company is taking steps to reach them.

- Here’s more news from HP as it expands automation solutions for advancing 3D printing path to production. HP’s Jet Fusion automation solutions are designed to simplify workflows and reduce costs for high-volume 3D production. The company has also expanded its materials, HP Digital Production Suite and HP Digital Production Services for polymer and metal customers.

Related Content

Why This Photopolymer Developer Wants Prototyping to Go “Massless”

High-performance materials supplier polySpectra is embracing augmented reality (AR) with a new tool called Massless intended to reduce unnecessary 3D printing.

Read MoreHow Large-Format 3D Printing Supports Micro-Scale Hydropower

There is potential hydroelectric power that has never been unlocked because of the difficulty in capturing it. At Cadens, additive manufacturing is the key to customizing micro-scale water turbine systems to generate electricity from smaller dams and waterways.

Read MoreEvaluating the Printability and Mechanical Properties of LFAM Regrind

A study conducted by SABIC and Local Motors identified potential for the reuse of scrap reinforced polymer from large-format additive manufacturing. As this method increases in popularity, sustainable practices for recycling excess materials is a burgeoning concern.

Read MoreCopper, New Metal Printing Processes, Upgrades Based on Software and More from Formnext 2023: AM Radio #46

Formnext 2023 showed that additive manufacturing may be maturing, but it is certainly not stagnant. In this episode, we dive into observations around technology enhancements, new processes and materials, robots, sustainability and more trends from the show.

Read MoreRead Next

4 Ways the Education and Training Challenge Is Different for Additive Manufacturing

The advance of additive manufacturing means we need more professionals educated in AM technology.

Read MoreHybrid Additive Manufacturing Machine Tools Continue to Make Gains (Includes Video)

The hybrid machine tool is an idea that continues to advance. Two important developments of recent years expand the possibilities for this platform.

Read MoreAt General Atomics, Do Unmanned Aerial Systems Reveal the Future of Aircraft Manufacturing?

The maker of the Predator and SkyGuardian remote aircraft can implement additive manufacturing more rapidly and widely than the makers of other types of planes. The role of 3D printing in current and future UAS components hints at how far AM can go to save cost and time in aircraft production and design.

Read More