Incus Successfully Tests Lithography-Based Metal Manufacturing for Lunar Environment

The project aim was to develop a sustainable process that uses lunar resources and recycled scrap metals (eventually contaminated by lunar dust) to produce spare parts on-site which could help and enhance human settlement on the moon.

Share

Read Next

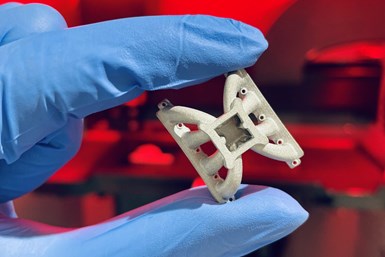

Incus, a provider of lithography-based solutions for additive manufacturing (AM), has successfully completed its joint 18-month project with the European Space Agency (ESA), OHB System AG and Lithoz GmbH to test the potential of 3D printing and zero-waste workflow for the lunar environment. The ESA-sponsored project, developed by Incus and Lithoz GmbH under the coordination of OHB System AG as prime contractor, aimed to research the feasibility of processing lunar scrap metals (which might be recovered from debris from old missions or old satellites) to produce high-quality printed parts using AM, specifically lithography-based metal manufacturing, also taking into consideration potential in situ contamination by using lunar regolith simulant.

The project’s goal was to develop a sustainable process that uses lunar resources and recycled scrap metals, eventually contaminated by lunar dust, to produce spare parts on-site which could help and enhance human settlement on the Moon. The successful use of lunar resources and recycling of scrap metals is vital to the creation of a sustainable Moon base. Lithography-based metal manufacturing (LMM) was selected for its ability to print from recycled metal waste and its ease and safety during printing and postprocessing.

The biggest challenge for lunar AM is the harsh lunar environment, including the atmosphere, gravity, temperature, radiation and the potential contamination of moon dust. However, the Hammer Lab35 Incus 3D printing solution was able to print recycled titanium powder while maintaining proper part quality. The produced parts demonstrated a high level of strength, comparable to Metal Injection Molded Titanium parts standards (1,000-1,050 MPa).

The LMM technology used in the project can print from scrap metals using premixed feedstock, without free and loose powder and the need for any support structures, offering a sustainable zero-waste workflow. The project also included the development of a green binder and the optimization of preprocessing and postprocessing steps to print and test different demonstrators for future lunar applications.

The project's results have important implications for the future of space exploration and the development of sustainable Moon bases. “This project has proven that LMM technology is able to use recycled powder for the feedstock material and provide sustainable zero-waste workflow,” says Dr. Gerald Mitteramskogler, Incus CEO. “We expect that further developments in metal recycling technologies will open the way to metal materials with more settled sintering processes for the lunar environment.”

The project’s optimal scenario for the 3D printing habitat on the Moon base is comparable to that on Earth, with reduced gravity and human-graded radiation shielding, ensuring that no major modifications or redesigns are required aside from the size, mass and volume reduction of the 3D printer. “Considering the challenge of bringing humans back to the Moon and building a base, the topic of in-situ resource utilization (ISRU) is gaining significant momentum. Projects like this, recently completed by Incus and project partners, demonstrate that manufacturing methods like LMM are very good candidates to support such an endeavour,” says Dr. Martina Meisnar, materials and processes engineer at ESA.

According to Dr. Martin Schwentenwein, head of material development at Lithoz, this successful collaboration showed that lithography-based AM techniques are among the most promising candidates to let 3D printing in space become a reality in the future.

The use of local lunar resources, as well as the recycling of old spacecraft, are essential for a sustainable and Earth-independent Moon base. “Through this project, it was proven that the LMM technology is able to use recycled powder sources as feedstock material. Furthermore, it was demonstrated that contaminations for the powder sources by using lunar regolith simulant are manageable, especially from the perspective of the printing process,” says Francesco Caltavituro, OHB system engineer for the project. “With those aspects in mind, as well as the future challenges already foreseen and anticipated, upcoming research and development will be able to continue and open up further the way toward a sustainable Moon settlement finally released from Earth dependency.”

- Read more about the Incus project to test 3D printing spare parts in space. The project goal was to assess the feasibility of processing scrap metals available on the moon’s surface to produce a high-quality final product via a zero-waste process.

- Here are more details about stereolithography for metals producing detailed parts. Lithography-based metal manufacturing (LMM) is a technique developed by Incus using a curing process based on stereolithography to build green metal parts with photopolymer.

Related Content

Additive Wins on Cost, Plus Process Monitoring and More from RAPID + TCT 2023: AM Radio #38

Additive manufacturing is finding success as a cost-effective manufacturing method. New options for process monitoring are now available. DED is getting more precise. 3D printed chairs! What we learned and observed at RAPID + TCT 2023.

Read MoreHow Large-Format 3D Printing Supports Micro-Scale Hydropower

There is potential hydroelectric power that has never been unlocked because of the difficulty in capturing it. At Cadens, additive manufacturing is the key to customizing micro-scale water turbine systems to generate electricity from smaller dams and waterways.

Read MoreThe AM Ecosystem, User Journeys and More from Formnext Forum Austin: AM Radio #43

Sessions and conversations at the first U.S. Formnext event highlighted the complete additive manufacturing ecosystem, sustainability, the importance of customer education, AM user journeys and much more.

Read MoreWhy This Photopolymer Developer Wants Prototyping to Go “Massless”

High-performance materials supplier polySpectra is embracing augmented reality (AR) with a new tool called Massless intended to reduce unnecessary 3D printing.

Read MoreRead Next

At General Atomics, Do Unmanned Aerial Systems Reveal the Future of Aircraft Manufacturing?

The maker of the Predator and SkyGuardian remote aircraft can implement additive manufacturing more rapidly and widely than the makers of other types of planes. The role of 3D printing in current and future UAS components hints at how far AM can go to save cost and time in aircraft production and design.

Read More4 Ways the Education and Training Challenge Is Different for Additive Manufacturing

The advance of additive manufacturing means we need more professionals educated in AM technology.

Read More3D Printing Brings Sustainability, Accessibility to Glass Manufacturing

Australian startup Maple Glass Printing has developed a process for extruding glass into artwork, lab implements and architectural elements. Along the way, the company has also found more efficient ways of recycling this material.

Read More