Composites

Eaton Developing Carbon-Reinforced PEKK to Replace Aluminum in Aircraft Air Ducts

3D printable material will meet ESD, flammability and other requirements to allow for flexible manufacturing of ducts, without tooling needed today.

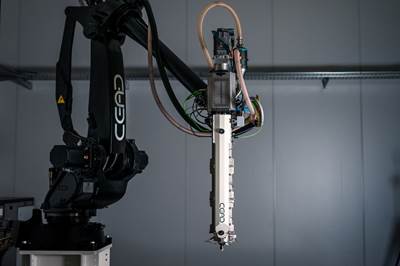

Read MoreCEAD and Adaxis Integrate Technologies for More Efficient Robotic Large Format 3D Printing

CEAD’s methodology for large-format 3D printing converges within Adaxis’ AdaOne software for the Flexbot platform, giving Flexbot users a smoother, more efficient experience with increased consistency, reliability and build quality, while minimizing potential issues.

Read MoreAirtech Qualifies Dahltram Resins for Integration With Caracol’s Heron LFAM Platform

The companies say this qualification will support Caracol in its efforts to offer Airtech’s Dahltram resins to its customers across the globe.

Read MoreJuggerBot 3D Awarded $4 Million by Air Force to Develop Large Format Hybrid Additive System

The project focuses on advancing the ability to print a thermoset composite material that can transform the way an aircraft structure is designed, fabricated and sustained for limited-life aircraft.

Read MoreCRP Technology’s Windform SL Is Lightweight, Rigid Composite for SLS, LPBF

Windform SL is well suited for the the production of sophisticated, efficient components across various fields, from aerospace to automotive, ensuring light weight without the need to reduce thickness.

Read MoreAircraft Ducts 3D Printed in Composite Instead of Metal: The Cool Parts Show #68

Eaton’s new reinforced PEKK, tailored to aircraft applications, provides a cheaper and faster way to make ducts compared to formed aluminum.

WatchLithoz Invests in AMAREA 3D Printing Technology Which Combines Up to Six Different Materials in a Single Print Run

The company is looking to actively support a new dimension of 3D printed, functionally graded components.

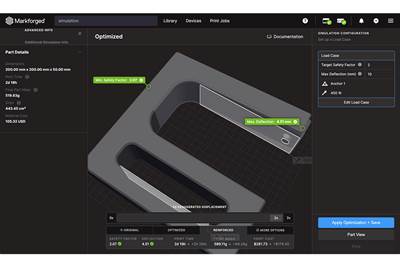

Read MoreMarkforged 3D Printing Simulation Software Validates Composite Part Strength

The virtual testing validates the strength of advanced composite parts and automatically optimizes print parameters to lower cost and speed production.

Read MoreVideo: Reinforcing (and Joining) Parts After 3D Printing

Reinforce 3D has developed a method that can be applied to strengthen 3D printed parts by feeding continuous fiber and resin through them. The technique also enables joining parts of various materials and manufacturing methods.

WatchProlay 7Q 3D Offers PLTM Technology for Polymer, Composite Additive Manufacturing

The Prolay 7Q can produce components 1.5 to 5 times faster than conventional AM methods and produce parts with different layer thicknesses in a single process.

Read More