Additive Design Offers New Opportunities in Grinding

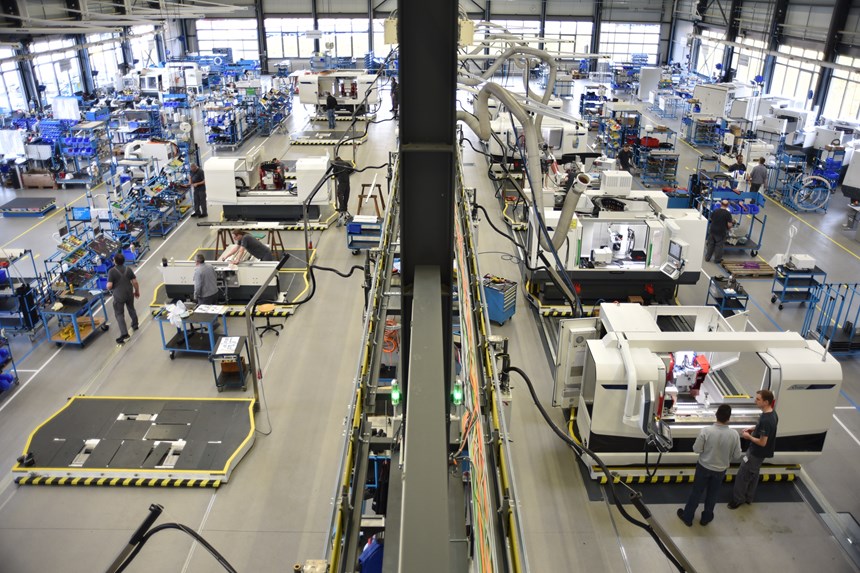

Swiss grinding machine manufacturer Studer leverages additive manufacturing technology to build parts such as hydraulic components, machine covers and coolant nozzles for its high-precision machines. The result is optimized lubrication during grinding, increased service life of the grinding wheel, and quick and easy parts assembly during machine production.

Share

Read Next

Grinding workpieces with an accuracy of a tenth of a micron can truly be called an art. Practicing this art requires perfectly adjusting and tuning every single process parameter including vibration, heat generation, noise emissions, control, software as well as cooling lubricants, often called the “fluid tool” of the grinding process.

To better manipulate the fluid tool, Switzerland-based grinding machine manufacturer Studer has now released a new, customized, in-house designed 3D-printed coolant nozzle called SmartJet, which is designed to optimally distribute the right amount of coolant in the correct flow rate and pressure to the right spot during the grinding process.

“Precise grinding requires a lot of experience, the right parameter settings and optimization in many areas including cooling,” Studer CSO Sandro Bottazzo says. “The heat produced during the grinding process is critical in terms of workpiece quality. Relatively high friction effects in abrasive machining cause heat generation which can lead to thermal damage in the surface layer of a machined part; cooling and lubrication therefore play a decisive role during grinding.”

Besides the primary task of cooling the grinding process, the coolant lubricant can also carry out other tasks within the machine tool, for instance cleaning the grinding wheel of machining residues, flushing out chips from the machine or extinguishing the spark jet.

To convey the coolant lubricant to precisely the site in the machine tool where it is needed, coolant lubricant nozzles are used. While the direction, flow and exit speed of the coolant lubricant are set by nozzle and supply parameters which need to be precisely coordinated, the design of the nozzle itself has not changed much over the years.

3D-Printed Nozzle for Optimum Cooling

Studer has risen to this challenge. The new SmartJet nozzle is additively designed and produced by Irpd AG, with headquarters in St. Gallen, Switzerland. Irpd AG concentrates on the manufacture of industrial metal or plastic prototypes rangingto the production of small series of complex workpieces. “In 2015, United Grinding Group signed a cooperation agreement with university-affiliated Inspire AG for a joint venture that specializes in additive production processes,” Bottazzo explains. “There are two reasons for this joint venture; one is that we see enormous potential in AM technology and we need to take AM-knowledge and experience into our company. The second reason for the joint venture is to have the expertise and facilities to optimize our own machine design and production process to produce our machines even more efficiently by creating parts that are easier to install, that are more efficient, require less maintenance and offer productivity advantages for our customers.”

Each SmartJet nozzle is designed according to a customer’s individual workpiece and the respective grinding wheel to ensure conformal cooling close to the workpiece and grinding wheel. The nozzle can be made of plastics such as polyamid or metal using SLA and SLM processes, depending on the customer’s needs.

“Customized coolant nozzles offer the chance to cool the part/wheel exactly where necessary and thus minimize the amount of coolant in circulation, leading to a reduction of adverse environmental effects and cost.”

“We sit with our customers and discuss their workpieces and requirements,” Bottazzo explains. “When you grind workpieces to an accuracy of up to a tenth of a micron, you want the coolant to be exactly at the right spot to ensure optimum cooling. The heat generated due to the friction between the grinding wheel and the part supply nozzles and in the grinding zone isthe key to optimization of cooling and lubrication during grinding. Heat presents a major challenge during grinding, as it can lead to an unstable grinding processor or in the worst case to part damage (e.g. grinding burn) and thus to scrap, as the part can no longer fulfill its load requirements. Customized coolant nozzles offer the chance to cool the part/wheel exactly where necessary and thus minimize the amount of coolant in circulation, leading to a reduction of adverse environmental effects and cost.”

But the nozzle is only one piece of the puzzle when it comes to cooling. Before the fluid enters the nozzle, it passes through a circuit which includes a hydraulic block manifold which directs the flow of fluid in the system linking valves, pumps and actuators. Passageways in conventional manifolds often must be positioned to prevent cross-drilled channels from intersecting and allow enough material between channels to provide adequate strength. Auxiliary holes drilled to connect internal passageways may need to be plugged, creating the potential for a future leak.

“Using AM technology, where a high-power-density laser melts the metal powder into a homogenous part, flow channels can be placed exactly where they are needed, and in optimum size and shape,” Bottazzo explains.

The traditional manufacturing process can result in abrupt angled junctions between flow paths which can cause flow separation and/or stagnation—a major contributor to efficiency loss. By building a component in layers via 3D printing, designers can specify configurations that would be difficult or impossible using conventional manufacturing methods.

Reduced Turbulent Flow

With AM, for example, flow paths can be made with cross-sections that are square instead of round, reducing turbulent flow by 20 percent with the same channel width. Channel design can be optimized to achieve greater flow within a smaller space. Passageways connecting internal channels don’t have to be machined from outside a manifold, eliminating the need for hole plugs.

In addition to optimzed channels and flow capacity, the additive design also simplifies machine production. “The additively-made hydraulic block is more efficient in materials handling, storage and assembly as we have reduced the overall number of parts from five to one,” Bottazzo says. “In the past, the assembly of the hydraulic manifold block in our machines was rather complicated. The fitter had to step into the machine to fix the block and connect all hydraulic tubes. Today, all you need to do is to screw in the block and connect the tubes.”

Most of these developments come from Studer engineers—the company employs six engineers dedicated to additive manufacturing—and the engineers in St. Gallen, many of whom have been working with AM technologies for 20 years. These engineers “Think Additive,” Bottazzo says, which is important, as many machine tool builders do not have this knowledge yet. Studer is just one of many customers of Irpd, who also offer what they call “body leasing,” where customers can hire staff to help engineer their AM parts or to set the right parameters on their AM equipment.

“Our nozzles, the hydraulic block and various machine covers are just the beginning of our efforts to optimize our own machine tool design and production through additive manufacturing. We are continuously working on new ideas and designs.”

“Our nozzles, the hydraulic block and various machine covers are just the beginning of our efforts to optimize our own machine tool design and production through additive manufacturing,” Bottazzo says. “We are continuously working on new ideas and designs.”

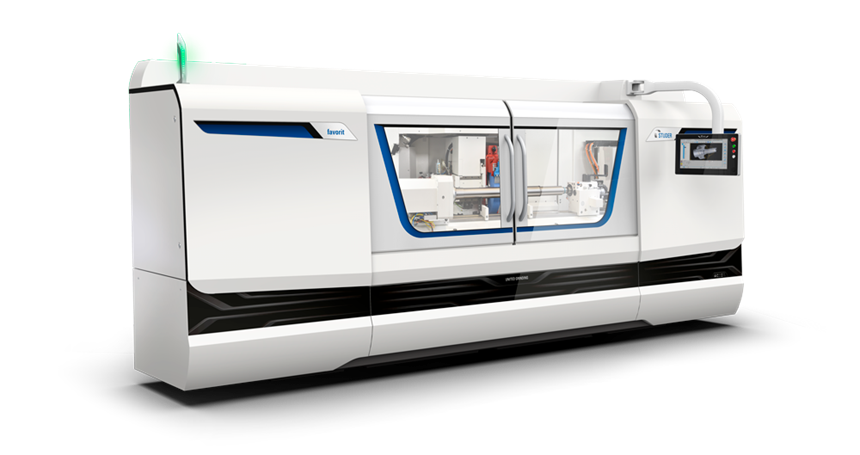

Four beta-customers are currently using Studer’s new coolant nozzles and the new hydraulic block is now integrated in the company’s new universal cylindrical grinding machine, the Favorit, which was unveiled at this year’s GrindTec exhibition in Augsburg, Germany.

Related Content

New Zeda Additive Manufacturing Factory in Ohio Will Serve Medical, Military and Aerospace Production

Site providing laser powder bed fusion as well as machining and other postprocessing will open in late 2023, and will employ over 100. Chief technology officer Greg Morris sees economic and personnel advantages of serving different markets from a single AM facility.

Read MoreDMG MORI: Build Plate “Pucks” Cut Postprocessing Time by 80%

For spinal implants and other small 3D printed parts made through laser powder bed fusion, separate clampable units resting within the build plate provide for easy transfer to a CNC lathe.

Read More10 Important Developments in Additive Manufacturing Seen at Formnext 2022 (Includes Video)

The leading trade show dedicated to the advance of industrial 3D printing returned to the scale and energy not seen since before the pandemic. More ceramics, fewer supports structures and finding opportunities in wavelengths — these are just some of the AM advances notable at the show this year.

Read MoreNew Electric Dirt Bike Is Designed for Molding, but Produced Through 3D Printing (Includes Video)

Cobra Moto’s new all-electric youth motocross bike could not wait for mold tooling. Parts have been designed so they can be molded eventually, but to get the bike to market, the production method now is additive manufacturing.

Read MoreRead Next

Hybrid Additive Manufacturing Machine Tools Continue to Make Gains (Includes Video)

The hybrid machine tool is an idea that continues to advance. Two important developments of recent years expand the possibilities for this platform.

Read MoreAt General Atomics, Do Unmanned Aerial Systems Reveal the Future of Aircraft Manufacturing?

The maker of the Predator and SkyGuardian remote aircraft can implement additive manufacturing more rapidly and widely than the makers of other types of planes. The role of 3D printing in current and future UAS components hints at how far AM can go to save cost and time in aircraft production and design.

Read More4 Ways the Education and Training Challenge Is Different for Additive Manufacturing

The advance of additive manufacturing means we need more professionals educated in AM technology.

Read More