What makes additive manufacturing (AM) distinct from other manufacturing processes? By some accounts a 3D printer is merely a machine tool running in reverse, applying material instead of cutting it away. But this oversimplifies the role that 3D printing can serve. An additive machine is not the equivalent of a machine tool, nor an injection molding press, because it comes with its own requirements related to materials, design, postprocessing, safety, and even inventory and accounting. It brings challenges, yes — but also opportunities to think differently about what and how a company is manufacturing.

In the very first episode of our new podcast AM Radio, cohosts Peter Zelinski, Julia Hider and I discuss what makes additive manufacturing distinctive among part production processes. And, we explore whether metal or polymer 3D printing is farther along as a production process. Listen to the episode above or on your preferred podcast app, or read on for a transcript of our conversation.

Transcript

Stephanie Hendrixson

Hello, and welcome to AM Radio, a new podcast from Additive Manufacturing Media where we'll tune in to what's really happening in additive. I'm one of your hosts Stephanie Hendrixson. In this first episode, we'll tell you a little bit about the show and then dive right in. We'll talk about what makes additive manufacturing distinctive among other manufacturing methods. And then the second half will. And then the second half, we'll discuss startups and talk about some specific companies that are able to manufacture a product because of 3D printing. That's all coming up on AM Radio.

Julia Hider

Okay. The AM Radio podcast is brought to you by the Additive Manufacturing Conference and Expo, the leading industry event focused on 3D printing for production plan to join us October 12. Through 14th at the Duke Energy Center in Cincinnati, Ohio. Learn more at AdditiveConference.com.

I'm Julia Hider.

Peter Zelinski

I’m Pete Zelinski.

Stephanie Hendrixson

And you just heard from me, I'm Stephanie Hendrixson. Welcome to AM Radio. This is a podcast about additive manufacturing, the use of 3D printing to make functional components, including end use parts. On the show, we're going to share success stories, we're going to tell you about the companies and the people that are using 3D printing successfully today, as well as talk about the challenges they overcame to get there, we're going to talk about the trends that we're seeing the new technologies that are coming out, and the opportunities for additive manufacturing, our goal is to paint a realistic picture of what's happening in am and also put it into context within manufacturing and within the world at large. But speaking of context, we should probably tell you a little bit about who we are. All three of us are editors of a publication called Additive Manufacturing Media. Pete, you're the editor in chief, so I'm gonna put you on the spot here. Can you explain what this publication is what we're all about what we're all about?

Peter Zelinski

We write about additive manufacturing. For manufacturers, we are part of this, we're part of this media company that that is all about manufacturing. And our brand within that company sort of recognizes how 3D printing is changing the possibilities for a lot of manufacturers. And we write about that. And we go out into the world and learn about that. And we visit companies making industrial 3D printing equipment, developing the technology, we go out and see how it's being used. And so our magazine is additive manufacturing. Um, part of the other ways we talk about it, we do The Cool Parts Show, a YouTube series

What this podcast is gonna let us do this thing we're doing anyway, which is we always get together and kind of like, share notes and share perspective on what we're seeing. So let's just do that in front of everybody. This is our first episode Julia. Where should we start?

Julia Hider

Well, something we all have in common is that we all rank for or have written for sister publication to Additive Manufacturing Media called Modern Machine Shop. That covers the metalworking industry. So I think a good place to start would be for us to sort of compare how 3D printing is different from other manufacturing methods.

Peter Zelinski

Yeah, like Yeah, I love that as a starting point. Machine tools. Um, yeah, we've all written for modern machine shop. And it's making like really basic. But with 3D printing, it's possible to make this conceptual error right from the beginning is a 3D printer. A machine tool, is a 3D printer, just a machine tool that adds material instead of cutting it away. And I'd argue it's not, that's not the right way to think about it. Because what 3D printing is doing as a part making process is different from what machine tools do

Julia Hider

How is it different from what a machine tool is doing? It's sort of just a reverse. Like, you could argue that it's reverse machine tool.

Stephanie Hendrixson

Well, so I guess, the first place I would take that is, there are so many different processes, some of them do look a lot like a machine tool running, like anything that's doing extrusion has like a gantry and a nozzle that's kind of moving, maybe in the same way that a machine tool might. But when you look at like some of the laser based processes, like it starts to look a little bit different. But I think the bigger point here is that when we see people adopting additive manufacturing, it's not that they just buy a new machine, put it out on the floor next to their machine tools, they have to start rethinking a lot of the ways that they're doing production, everything from, you know, the material, it's not coming in the form of barstock or billet anymore, it's coming in tubs of powder, or rolls of wire or something like that. And, and so the way that you think about your design, your materials, even your accounting, and inventory starts to shift.

Peter Zelinski

So that's right, I think that that gets that the difference is, the machine itself might move in x, y, z, like a like a metal cutting machine tool might what it is fitting into the organization in an entirely different way. And in a sense, it's even you're building the material, you're forming the structure of the material at the same time that you're making the geometry of the part. That's conceptually very different. And to use additive, well, there's a different kind of conversation between designer and manufacturer. And yes, yes, definitely, as you were saying, even the downstream stuff starts to change. Where are these parts go, is affected by the fact that you can make much more intricate components that maybe change how you think about assembly, and make components and much smaller batches that maybe change how you think about inventory.

Julia Hider

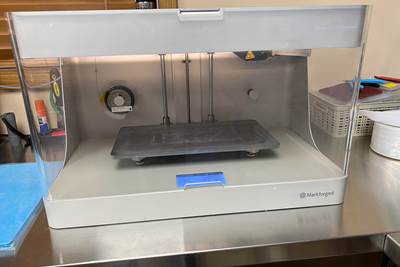

Yeah, I think all those are really good points. You know, you touched on design freedom, it's letting people make parts that can't be made in any other ways and just how they're treated differently. We visited a shop called RPG and they're traditionally machining manufacturing facility, a job shop and they got this metal x, metal 3D printer from MarkForged. So the metal printer is actually in the president's office, it's not out on the shop floor with the rest of the machine tools. And that just really highlights how these two processor processes are treated differently.

Stephanie Hendrixson

Yeah, so the two processes are treated differently. But I feel like this conversation is getting really heavy into metals. And there are a lot of other areas and materials that 3D printing is used for, I think we should talk about the difference between 3D printing and injection molding, because that's a process that looks that has some of the same challenges as machining, but it actually looks quite different. When you think about the core of the injection molding process is this mold, this tool that you've spent 1000s of dollars waited weeks to get, if you want to make changes to the design, it's going to be really difficult. And so if you can convert an injection molded part to a polymer 3D printing part or you can just start with Polymer. You have a lot of those design freedoms you you out, you have a lot of design freedoms, but maybe more important than that. You're not locked into that tool. You don't have that that startup cost to get into production. And if you want to make changes, you know, you can do that on the fly. So one of the great benefits of polymer 3D printing is that it's this tooling list process, we talked about that all the time, how you're not locked into one particular design, you're not locked into the expense of something like a mold, and you can make what you need in whatever quantity you need without doing that work upfront.

Julia Hider

And that's a good point. Stephanie. So we have, you know, metal 3D printing, and we have polymer 3D printing, which group Do you guys think is further along?

Peter Zelinski

Yeah. Further along, further along with with realizing the promise of these processes for for repeatable production? That's a good question. I'm gonna off the top of my head, I'm gonna say, Polymer. And let me Let's try to unpack why I feel that way. I'm certainly certainly in polymer part manufacturing. Additive gets to fill a big, obvious hole in existing plastic part making processes because injection molding is really great at higher volumes. But But doing small batches of parts. A plastics molding process just doesn't lend itself to that. The the notion of doing 3D printing as a way to get started making parts get started making parts maybe even while you're waiting for your mold tooling to come. It's a very natural fit and a very natural role for polymer additive manufacturing. Add to that add to that, Stephanie, why is what? Why is, if I'm right about that, polymer additive manufacturing a little bit farther along as a as a production process, approaching maturity,

Stephanie Hendrixson

I actually would agree with that. And I think part of it for me is when we talk about like production quantities, I feel like the numbers we've heard tend to be higher when it's a plastic plastic part. So like, the example that comes right to mind is the the COVID testing swabs were these companies, it was multiple companies working together, but they were producing millions of swabs over the course of weeks and months. But like Another example would be like two or three years ago, smile direct, made a big investment in multi jet fusion printers from HP. And they were saying they were going to print a million parts a year, which were tools not in use parts. But still, I feel like we hear higher numbers, and we hear examples like that. More on the polymer side. The other thing that comes to mind is, I think plastic 3D printing is in some ways easier to implement. Like, if you think about a powder bed fusion process with powdered metal, like it's not just buying again, it's not just buying the printer and putting it out on your shop floor, you need powder handling equipment, you need safety measures in place, you need PPE for the people who are going to be working with that machine. And then you also need a machine shop to deal with the post processing of that. Whereas on the polymer side, like there are systems that are going to require cleaning and they're going to require finishing and things of that nature. But you're much closer to a finished part when it comes out of the printer. And in some cases, what comes out of the printer can be the finished part on the on the plastic

Peter Zelinski

side. Yeah, that's right. And meanwhile in metal parts, we already have this really good solution for for relatively small quantities CNC machining. And so in metal additive is finding its wins in places where it can it can it can consolidate assembly and reduce that dramatically or bring intricate geometries that the machining process would be challenged to produce. But yeah, there's a there for some of these processes in metal, there is a safety and personnel related infrastructure investment that goes along with this not all of metal processes but but but many of the most established ones. Well, that's much more straightforward with polymer.

Stephanie Hendrixson

So did we do it? Did we answer the question? Which, which one is further along?

Julia Hider

Yeah, I think we're all, you know, pretty definitive that polymer is further along at this point. You know, we've talked about metal, we've talked about Polymer. Those are just two different types of additive manufacturing processes. And there's a lot more for us to talk about still.

Stephanie Hendrixson

So additive manufacturing has a different way of making parts. And we've talked about some of the advantages it has over machining and over injection molding and kind of where it fits in. And we'll talk about those other methods in future episodes as well. But it also changes who can be a manufacturer. So in the next part of the show, we're going to talk about startups and the new businesses that are being enabled by 3D printing. That's coming up after the break.

Julia Hider

The AM Radio podcast is brought to you by the Additive Manufacturing Conference and Expo, the leading industry event focused on 3D printing for production. The conference takes a practical applications-based look at the machines, materials and methodologies being used to create and use tools and components. The event is designed for owners, executives and engineers, as well as OEMs involved in durable goods manufacturing. Join the additive manufacturing team in Cincinnati, Ohio for two days of in-depth conference sessions, exhibits and networking opportunities with am experts. Also on the expo floor. Check out the finalist entries and the cool parts showcase a contest to find the next subjects of our video series. The cool part show, be sure to vote on your favorite. The Additive Manufacturing Conference and Expo runs October 12 through 14th. Find out more details and register at AdditiveConference.com.

Related Content

How to Build 10,000+ Shot Molds in Hours

Rapid tooling isn’t so rapid when it takes days to 3D print a metal mold, and then you still must machine it to reach the necessary tolerances. With Nexa3D’s polymer process you can print a mold in hours that is prototype or production ready and can last for more than 10,000 shots.

Read More3D Printing with Plastic Pellets – What You Need to Know

A few 3D printers today are capable of working directly with resin pellets for feedstock. That brings extreme flexibility in material options, but also requires greater knowledge of how to best process any given resin. Here’s how FGF machine maker JuggerBot 3D addresses both the printing technology and the process know-how.

Read MoreLarge-Format “Cold” 3D Printing With Polypropylene and Polyethylene

Israeli startup Largix has developed a production solution that can 3D print PP and PE without melting them. Its first test? Custom tanks for chemical storage.

Read MoreHow Large-Format 3D Printing Supports Micro-Scale Hydropower

There is potential hydroelectric power that has never been unlocked because of the difficulty in capturing it. At Cadens, additive manufacturing is the key to customizing micro-scale water turbine systems to generate electricity from smaller dams and waterways.

Read MoreRead Next

Additive Manufacturing and 3D Printing Are Two Different Things

And as AM continues to advance, the differences are becoming more pronounced and more important.

Read MoreHow Test Swabs Became 3D Printing's Production Win: The Cool Parts Show #15

Nasopharyngeal swabs for COVID-19 testing are one of the best production cases for 3D printing we've seen, pandemic or otherwise. Why AM is winning on speed, functionality and collaboration.

Read MoreJob Shop’s AM Journey Takes It from Production to Tooling

Despite the fact that RPG was prepared to start with production metal additive manufacturing, the job shop couldn’t ignore the benefits of 3D-printed tooling.

Read More

.jpg;width=70;height=70;mode=crop)

.png;maxWidth=300;quality=90)