The Future of Jewelry Manufacturing Is Custom, On Demand and Perfectly Sized

The Melvin sisters launched their startup, The Future of Jewelry, when they couldn’t find matching signet rings. Now, customers can design exactly the ring they want, to be produced affordably through 3D printing and/or lost wax casting.

The Future of Jewelry (TFOJ) represents an affordable, on demand approach to jewelry manufacturing. The company offers custom signet rings 3D printed in polymer starting at just $25, as well as rings in precious metals cast from 3D printed wax tooling. Images: The Future of Jewelry

“Mass-produced jewelry is a modern invention,” says Casey Melvin. “Until the 20th century, every piece of jewelry was made by a craftsman.” The craftsman allowed for customization, for unique jewelry for each individual wearer, but this artisanal approach has been largely displaced by mass production’s economy and speed. The company Casey co-founded and runs with her sister, Janine, in many ways promises a blend of these benefits. With design executed by software and a digital manufacturing process built on 3D printing, The Future of Jewelry (TFOJ) offers signet rings that are tailored to the size and customizations of the wearer. The company combines a return to the possibilities of the old way of making jewelry with the speed and cost savings of the new.

Casey Melvin (left) and Janine Melvin (right) departing for their summer abroad in 2016. A signet ring that Casey purchased on this trip prompted their search for custom jewelry, and eventually the launch of their company.

Neither Casey nor Janine has a background in 3D printing or engineering; both sisters were studying law until they launched their jewelry manufacturing company. The seed of the idea was planted while the sisters were spending a semester abroad at Oxford. They were hunting for matching souvenirs on a weekend trip to Spain when Janine spotted a gold signet ring she liked. The ring was too big for her fingers, but it did fit her sister. Casey bought it and had it engraved, with the thought that they would be able to easily find a match for Janine online. When that second ring proved elusive, the sisters began to explore options to make one themselves.

“That might have meant making molds and doing the etching manually,” Melvin says. “We weren’t locked in on the 3D printing aspect initially; we were locked in on recreating the product we liked so much.”

As the two sisters began investigating different technologies, they learned that 3D printing could be used to quickly manufacture tooling for lost wax casting, without requiring a large investment in molds or manual labor. Furthermore, they found 3D printing service bureaus that could manage both the printing and casting steps for them.

The sisters realized they had found not only the answer to their personal quest for a duplicate ring, but also a more flexible and personal way for other customers to buy jewelry, too.

The conventional gold ring on the left was the inspiration for The Future of Jewelry. Casey Melvin purchased the ring in Spain in 2016 and had it engraved. When the Melvins couldn’t find a match for Janine, they discovered a process for casting custom rings from precious metals using 3D printed wax tooling—the production method for the ring on the right.

On the left, Janine Melvin’s custom signet ring made in 2018 by TFOJ. The ring was cast from14K yellow gold using a 3D printed wax model.

Affordable, On-Demand and Digital Jewelry Manufacturing

The Future of Jewelry is intended to provide a custom, on demand and affordable option for signet rings, just like the one Janine Melvin eventually had made. Rather than traveling to a jewelry counter or selecting from an existing ring inventory, customers can create their own digital designs using the options and tools available through the company’s website.

The company now offers four precious metal ring options — silver as well as yellow, rose and white gold — plus lower-cost rings made from selective laser sintered (SLS) nylon and offered in enamel, acrylic or matte finishes. Rings are 3D printed in nylon or cast from the 3D printed wax forms by the service bureau Shapeways and its partners.

While the Melvins expect to continue using service providers as the business scales, they are now making some of the lost wax casting models themselves using a resin-based digital light processing (DLP) 3D printer. This machine can produce 55 wax ring forms in a single build run overnight, allowing for high mix production with frequent turnover. Each ring can be different, sized and designed precisely for the person who will wear it.

With a digital design file and sacrificial wax tooling, every ring ordered through The Future of Jewelry can be different.

Custom Manufacturers Have to Be Software Developers

For as much as 3D printing enabled the new jewelry maker’s business, the production side of this business has been relatively straightforward, the sisters say. But making custom design easy requires robust and easy-to-use software, and much of the startup’s development effort has focused here. 3D printing is a digital process that needs digital input — and for a custom item, at least some of that input needs to come directly from the customer. As makers of other 3D printed custom and on-demand products have found, success requires approaching the problem less like a manufacturer and more like a software developer.

In fact, of the seven employees who now work for The Future of Jewelry, four are dedicated to developing and iterating the online shopping experience. “In the beginning we probably went through two or three different outsource companies that build mobile apps and things like that,” Melvin says. “But eventually we figured out we needed to bring this in house to really delve into these issues.”

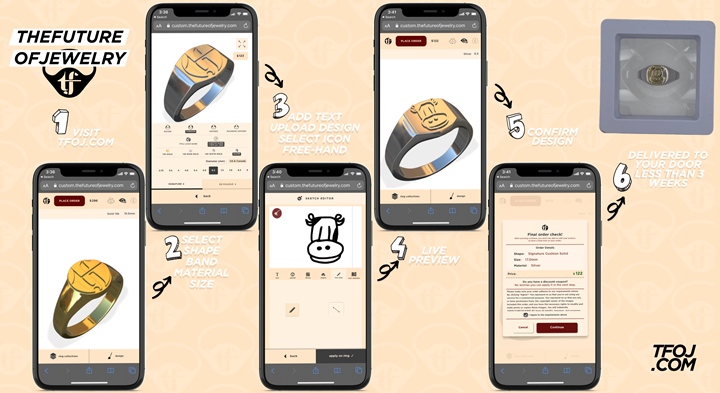

It took TFOJ’s team of three developers and one graphic designer a full year to build out the company’s interactive “sketch editor,” which customers now use to order. Through this interface, users are prompted to choose a base design, select a material, and customize their signet ring with text and simple images. The editor prices the ring according to its material volume, and once the order is placed and paid for via Shopify, the STL file is sliced and passed to a 3D printer.

Customers don’t need a special app to order from The Future of Jewelry. The sketch editor on the company’s website is accessible through a browser, and allows the customer to customize the ring design with text, icons and even drawings.

The Future of Jewelry has had to work through some technical issues on the way, including building connections from the sketch editor to its slicer and 3D printer, and figuring out how to size the rings. Not all of the challenges were related to software, however; sizing in particular has proven to be a hurdle.

Standard ring sizes are arguably a relic of mass production, one that simplifies a manufacturing process based on tooling but does not necessarily serve the end customer. While many consumers may know a ring size that fits, the number they have in mind is likely to be a “good enough” size instead of one that fits just right. The Melvins realized that offering truly custom jewelry would require greater freedom in sizing in order to fit wearers properly.

Rings can still be purchased based on standard sizes, but the company hopes for something more precise: to help customers learn their size in millimeters for greater accuracy. TFOJ has developed two tools to enable this. If a customer already owns a ring that fits well, he/she can use the company’s iPhone photogrammetry app to take a photo of that ring on a standard rounded-edge card such as a credit card or ID; a proprietary pixel analysis algorithm analyzes the photo to determine the ring’s inner diameter. Or, the customer can go to caliper.tfoj.com from any browser to access a digital caliper (again, scaled with a card) and measure his/her finger.

Custom Design Means Customer Re-Education

Buying a ring based on its diameter in millimeters does not come naturally to consumers conditioned for mass produced jewelry, nor does designing the jewelry themselves. To some extent buyers have to be reeducated, Melvin says. But once they “get it,” the enthusiasm is clear. “Jewelry can be special. Jewelry can be one of a kind. It doesn’t have to cost exorbitant amounts,” she says.

Part of The Future of Jewelry’s mission is to make custom jewelry manufacturing more affordable. The company offers a low-cost line of 3D printed rings like this one made with selective laser sintered (SLS) nylon. Several postprocessing and coating options are available for these polymer rings.

For now, TFOJ is focused on building brand recognition through advertising campaigns on Instagram, Amazon Fire TV and other consumer-facing platforms. Initial target customers for the custom rings include fashion and technology enthusiasts.

“Jewelry can be special. Jewelry can be one of a kind. It doesn’t have to cost exorbitant amounts.”

But the Melvins also recognize that their product could be many buyers’ first connection to 3D printing, and see it as a potential opportunity to evangelize the promise of this technology. The company recently partnered with 3Degrees’ Mike Vasquez to develop a pilot program for affordable high school class rings and is currently in discussions to bring this concept to a large public school district.

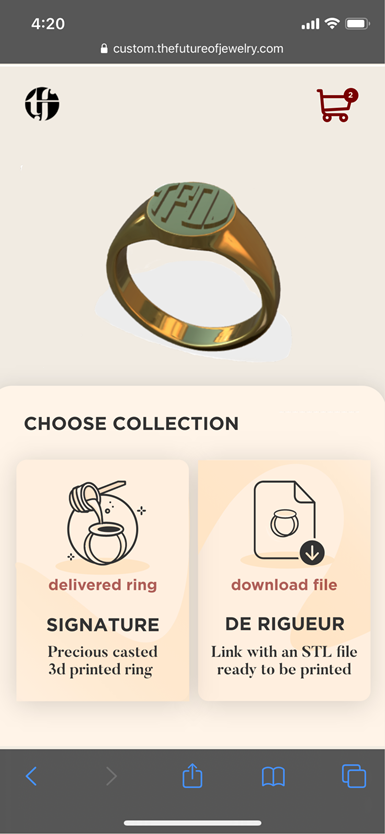

A new option coming to TFOJ customers in June: the ability to download and print their own “De Riguer” rings designed through the company’s sketch editor.

Beyond a business opportunity, TFOJ sees projects like this as a chance to get students excited about 3D printing. The company is also preparing to launch an e-learning program that will focus on the past, present and future of jewelry manufacturing; the first class will be available to a small group of students who are members of the robotics team at The Ogden School in Chicago.

Looking forward, The Future of Jewelry sees avenues toward more customer-involved and local jewelry manufacturing. By the end of June 2020, customers will have the option to download and print the STL files of custom rings themselves. Another future possibility could be distributing manufacturing to customers’ local jewelers, which often have casting capabilities. The company’s software could also spread, allowing other products to be made through a combination of 3D printing and custom design through an online portal.

“We do see that a component of our company is going to be allowing other brands to use some of our tools,” Melvin says. “All the trends are pointing that more jewelry will be bought online.”

Related Content

Copper, New Metal Printing Processes, Upgrades Based on Software and More from Formnext 2023: AM Radio #46

Formnext 2023 showed that additive manufacturing may be maturing, but it is certainly not stagnant. In this episode, we dive into observations around technology enhancements, new processes and materials, robots, sustainability and more trends from the show.

Read MoreHow 3D Printing Will Change Composites Manufacturing

A Q&A with the editor-in-chief of CompositesWorld explores tooling, continuous fiber, hybrid processes, and the opportunities for smaller and more intricate composite parts.

Read MoreTaking the Leap into Additive Manufacturing

SolidCAM’s partnership with Desktop Metal, and its in-depth experience in combined metal 3D printing and CNC finishing, is aimed at making additive manufacturing accessible and profitable for job shops and other manufacturers.

Read MoreHow Hybrid Tooling — Part 3D Printed, Part Metal Shell — Accelerates Product Development and Sustainability for PepsiCo

The consumer products giant used to wait weeks and spend thousands on each iteration of a prototype blow mold. Now, new blow molds are available in days and cost just a few hundred dollars.

Read MoreRead Next

Fitz Frames Brings Mass Customization to Eyewear with Affordable 3D Printed Glasses Frames

Glasses don’t need to be ill-fitting and frustrating to buy. Fitz Frames offers a different kind of shopping experience (using augmented reality and 3D measurement) to produce custom glasses with 3D printed frames that are affordable, durable, comfortable and stylish.

Read MoreGantri’s 3D Printed Luxury Lighting Brings Designers Closer to Consumers

The San Francisco startup is changing designer lighting with a designer-forward online marketplace and just-in-time delivery enabled by 3D printing.

Read MoreAdditive Manufacturing and Metal Casting

How is additive manufacturing disrupting metal casting? A hybrid approach to consider.

Read More

.jpg;width=70;height=70;mode=crop)