Additive manufacturing can provide advantages in the production process including more efficient material usage, reduced waste and potentially lower energy consumption. It may also lead to benefits in the use of a component, such as lightweighting an aerospace bracket to reduce the amount of fuel that aircraft needs to carry and use. But AM is a manufacturing process like any other, and its environmental impact must be evaluated according to the same standards as other manufacturing methods. In many cases that evaluation does not reveal a clear sustainability advantage for additive, but rather a series of trade-offs relative to competing approaches. In this episode of the AM Radio podcast, I discuss some of the recent studies into AM’s sustainability benefits with Dr. Tim Simpson, and we explore the various factors that play a role in assessing AM’s impact on resources and the environment.

Transcript

Stephanie Hendrixson 00:05

Is 3D printing a more sustainable manufacturing process? Where are we in terms of understanding all the potential factors involved in making that assessment? Tim Simpson joins me to talk about what's happening in industry and research coming up on AM Radio.

Jodee McElfresh 00:26

This episode of AM Radio is brought to you by Formnext Forum Austin, the first of a series of Formnext events coming to the United States. Find more information at Formnextforum.com.

Stephanie Hendrixson 00:41

Welcome to AM Radio, the podcast where we tune in to what's happening in additive manufacturing. I'm Stephanie Hendrixson. And I'm joined again today by Dr. Tim Simpson from Penn State University. Hi, Tim.

Tim Simpson 00:50

Hey, how you doing, Stephanie?

Stephanie Hendrixson 00:51

Good, how about you?

Tim Simpson 00:52

Good. Great to be back. And please, Tim, that doctor sounds so so formal.

Stephanie Hendrixson 00:57

Got it. So Tim, today, I want to have a conversation about sustainability as it pertains to additive manufacturing, like this is something I got really into in 2020. It was kind of like my pandemic project was trying to find the ways that additive manufacturers and suppliers were thinking about these issues. It was sort of a difficult task back then, like people, if they were thinking about it, they weren't necessarily talking about it. I feel like it's more of the top of people's minds now. But there's still just like a lot to think about and wrap your head around. And certainly greenwashing is still a big problem in this industry. So, I guess let's talk a little bit about the ways that sustainability is playing out in industry and applications, what's going on in kind of the research sphere? And then I want to get into what are the big questions and the things that we still need to figure out, but maybe just as a starting point, like what are your first thoughts when you think about additive manufacturing as it relates to sustainability?

Tim Simpson 01:56

Good question. I think sustainability is a hot topic in a lot of industries right now, not just additive manufacturing. And I agree there is a good bit of greenwashing going on across the board, I think both the opportunity and the challenge when it comes to additive manufacturing is trying to really translate the benefits of additive fabrication into meaningful metrics related to sustainability. And so if you think about lightweighting components, if you think about distributed manufacturing, making things locally or regionally versus globally, there are ways of measuring the benefits in terms of less material usage, less energy consumption, less carbon footprint, the challenge is in coming up with accurate estimates that are grounded in the realities of what additive can really do today, when the work is being done.

Stephanie Hendrixson 02:46

Yeah, I think like finding meaningful ways to quantify some of this stuff, and not just base it on assumption. So yeah, lightweighting is great. But do we know for sure that this 3D printed metal component is just because it's lighter weight, is it actually, quote unquote, greener than the thing that it replaced? And I think that's where a lot of like the greenwashing that I've seen kind of comes into play. It comes down to sort of like lazy marketing, just, this is an additive component, or this is a tool for additive manufacturing, and therefore it is more sustainable than what came before. That's not necessarily the case, or we don't always have enough information to make that assessment right now,

Tim Simpson 03:23

Lazy marketing, I like that. Yes, it's just, it's just blanket, yes, it's additive, therefore, it's greener, more sustainable. I agree. That's, that's not good for any of us in the industry. And certainly, you know, to your point, that lightweight component, you could pull that apart in different ways. Yes, it's then on an airplane, you know, less fuel consumption these things, but, but I flip it around and think also, hey, if I have a lighter weight component, I'm then using less material to make it which is then better material utilization, I'm using less machine time to manufacture it, which means I'm using less energy to make it, there's less waste because my buy-to-fly ratio is, is reduced significantly for many aerospace components, among others that we see. So again, I think having a good baseline of more traditional manufacturing processes being machining, casting, forging, and others, right, we need if we want to say additive is better how, how well have we assessed or how well can we assess these more conventional manufacturing means to make that direct comparison?

Stephanie Hendrixson 04:26

I think that's a really important point. And like looking at some of the lifecycle assessments, some of the studies that do exist in additive manufacturing, they're using tools that were developed for other industries, like additive is not special in the sense that we need like a totally different methodology. It's just that it's newer, and we don't always have that body of data built up about, you know, how much energy does the machine use or what goes into making some of these materials. And so it's kind of like filling in those gaps. But this is not a unique problem to additive. It's a manufacturing problem and other industries, other types of technologies have had to confront this as well.

Tim Simpson 05:03

Yeah, lifecycle assessment for any process is, is a challenge. And, you know, if you want to be able to say that additive is, is better than this process or that, you've got to have a baseline, you got to have a comparison there. And so making sure that you have an apples-to-apples comparison that is fair, all the way from raw material to finished part and/or use of that part, right, you got to capture all that steps for the additive process, postprocessing, you got to capture it for all the steps in your casting, and you're forging, whatever that that may be. And those, there's research efforts underway there, just like there is in additive manufacturing. So, there are no easy software solutions, tools or methods out there that capture all of that information readily, quickly and and give you that comparison.

Stephanie Hendrixson 05:53

So yeah, there's a lot that goes into, like, thinking about what sustainability is, thinking about lifecycle assessment. And it does have to include all of these different pieces of the additive manufacturing workflow, right. And the interesting thing that I see playing out in industry is that people are focused kind of in their own little silos, there are interesting things happening in researching and developing products around this idea of sustainability, but it's happening kind of in like some specific buckets. So like materials is a huge one. There are lots of companies providing materials for additive manufacturing that are, they're thinking this way and talking this way about using recycled feedstock, creating bio-based materials, using materials that are going to biodegrade or be compostable. That's certainly a huge area of interest.

Tim Simpson 06:42

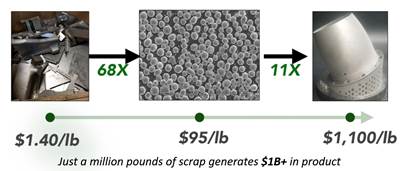

Yeah, I think there's lots of companies and efforts underway just looking at you know, for instance, recycled materials. So, if you stop and think about, like, within a university setting, right, how many failed prints do you see from students that are just learning how to use a material extrusion system or something else? And you get a whole pile of plastic spaghetti, that you're just like, am I now going to scrap that and throw that away? We actually had an art exhibit, on sort of recycled plastic. So looking, somebody had gone and, you know, the spaghetti prints from our Maker Commons in our library that then was turned into artwork, sort of thing just to say, hey, yeah, additive manufacturing, may, may use less material, maybe more sustainable, but look at all these failed builds that were along the way. And now you've got this issue. So we've actually had student projects, and I know others as well, right? Can we take, take that filament, take those prints, grind it up, turn it into new filament to then reuse it? So that's certainly underway. And while you may or may not be able to do that for some structural components, certainly, if you're making more bobblehead dolls or figurines, then sure recycled filament is going to be just fine. I've also talked to, you know, in the metal space, MolyWorks and others I know are out there looking at how do we, if we have a component we're trying to replace, right? Can we take that component, grind it up, turn it back into feedstock to then feed my powder bed fusion system, my DED system or whatever there and try and reuse much of that? You know, I would like to think, all right, well, let's look at that material consumption, the energy needed to break it down back to the raw material, put it in the right form for the feedstock, do the quality control on it, to then be able to get there, you certainly see companies that are popping up trying to attack that specific problem, in addition to finding new and or better ways to make material feedstock for different additive processes. So some of the, you know, gas atomization, water atomization, plasma methods for creating titanium among others, they, they consume a heck of a lot of energy, right, we had a Sciaky system here and some of these other systems using electron beam, plasma, you need a lot of energy to run that process. So hopefully, though, you're, you're processing less material in a shorter amount of time. So in the end, hopefully, it's all better so, so you do see, hey, let's improve the energy use consumption in the material space, in that process space. And then of course, all of that, that postprocessing space as well. Can we design our parts or modify our parts for additive to minimize postprocessing the, the additional machining, heat treatment, etching or whatever that are going to just add more energy consumption and increase the potential environmental impact of that process and the whole workflow?

Stephanie Hendrixson 09:32

Yeah, the energy point is really interesting. And it reminds me of like these lifecycle assessments that 6K Additive has done, they've done I think, nickel and titanium, looking at the energy consumption, the different resources and things that go into producing the materials that they make. And so they have a slightly different process for producing metal powders, where it's mostly mechanical, like they're able to do a lot of recycling and they sort of like grind and mill it down to size and then put it through this process that they call a UniMelt, where all of those little powder fragments are going through like a plasma beam. And it's basically just kind of like spheroidizing them, making them round. And they went through this lifecycle assessment with a third party did the research, they used industry standard type tools and found that this process uses less energy than some things like gas atomization. And so they were able to follow the whole supply chain from the materials being extracted or being recycled through getting processed through this UniMelt process, and then getting packaged and sent out to the customer. That's as far as the study went, like 6K has no control over what a user is going to do with that powder or what they're going to make or how that part is going to be used. But they did a pretty thorough study just to look at the material production and try to, you know, characterize what is going into that in terms of resources and energy and what types of emissions or other waste might be coming out on the other side.

Tim Simpson 09:32

Yeah. And I think it's a bit easier to do sort of head-to-head comparisons of okay, how can I make titanium powder, I can do it with this method, this method or this method, and let's measure it from raw material to, as you said, when it's packaged and sent to the customer. What the customer then does with that, how they use it, there's a whole other assessment that needs to be done. And I think that's the challenge with measuring sustainability and some of these metrics is you need the whole process chain, from the materials, the process, the postprocess, the delivery, the use, the end of use, what are they doing with it? And so that's I think the challenge right now in the industry and with other manufacturing processes, too, is it's easy to do small buckets or compartmentalized analyses, but to put it all together into an integrated model that is comprehensive, accurate and fair across that is just, it's a challenge, right, there's still a lot of work that needs to be done in that domain. So I think we'll see a lot more of those efforts underway. And certainly going on in the academic and university research communities.

Stephanie Hendrixson 12:05

It comes back to this question of who is responsible for this material, for these parts, for this process? And there's no real clear answer, like everybody sort of needs to be involved. And I'm not sure that we've seen like a really great example of like an end-to-end collaboration for a study or for even a production situation yet.

Tim Simpson 12:24

Agree, and to the other thing to your point, you commented on this earlier is a company that's trying to tout their process for making materials or parts is more sustainable, uses less energy, etc. Right? You need to get then a third party and independent sort of unbiased person or group to do that assessment for you. Because of course, everybody Oh, you did it yourself? Yeah, of course, you look better, right? They're gonna, they're gonna immediately question that naturally. Yeah. So then now we're talking about, oh, well, we now need to get third parties interested in this assessment. And they haven't necessarily been doing additive yet. So now we got to teach them about well, what does it mean for this additive process? How are my powders being made, you know, these folks are out there, but they're not necessarily aware of what's in the additive space. And now we got to get them trained and ramped up in all of this, right. So again, this notion of having a tool or a company that's sort of shovel-ready to go with that assessment is, you know, I think that's lacking, but, but it's lacking in a lot of manufacturing industries out there as well. We recently completed a review paper with Kate Whitefoot and her team at Carnegie Mellon, looking at sort of the environmental and economic benefits of additive manufacturing. And, and there's really only been about 20 studies or so that have tried to measure head-to-head comparisons of additive, you know, versus a conventional manufacturing process. And of those 20 or so studies, right, there's only about maybe six or seven metrics that people are using, as we've talked about. It's energy consumption, it's carbon footprint, you know, material utilization, perhaps there's something related to the, to the toxicity or the type of material that's being used and whatnot. So it's still fairly early in terms of the renewed interest in sort of lifecycle assessment and sustainability analysis of additive manufacturing and others. But certainly, I think there's a big opportunity there for us if we can come up with some good metrics and methods and tools to support this. I know a lot of companies that are hungry for that information and want to be able to use it

Stephanie Hendrixson 14:32

Thinking about the different criteria that are typically used in these lifecycle assessments. Is there anything that's missing for additive manufacturing, anything that is different?

Tim Simpson 14:42

Well, I think, I think an easy one to capture that we didn't see a lot of in the review that we did was just looking at sort of material consumption and waste, right. And so if you think about in aerospace, sort of the average buy-to-fly ratio of 10-to-1, 11-to-1, that's a lot of scrap material, a lot of waste. Now, there's different ways of removing all of that material, right? But just look at, let's call it 10-to-1 to do the math easy, right? If I, if I'm buying 10 pounds of material and only one pound flies, I'm wasting 90% of that. I think I did that math, right, versus in additive, if I'm printing the part, I can't get a 1:1 buy-to-fly ratio. But, if it's 1.5-to-1 or 1.2-to-1, then the amount of material that I'm consuming and wasting once I, you know, machine it to meet the final requirements is significantly less than the traditionally made component. And so just looking at that material savings, and those material benefits alone can certainly be translated to, you know, reduced environmental impact and improved sustainability, right?

Stephanie Hendrixson 15:49

It also gets pretty tricky in some of the additive processes where you've got excess powder that wasn't melted in, in one cycle. Can you reuse it into the next build? And if so, like, how many times and how do you mix it?

Tim Simpson 16:01

Great. Yeah, great point. I thought of that as I was coming up with that example on the fly. But certainly people are looking at the recyclability of the powder of that feedstock. Right. And certainly, as you go larger and larger with powder bed fusion and others, and recyclability is key to being able to make the economics work. As you go bigger, though, people are now looking at DED, directed energy deposition, wire feed. So now I'm fully consuming my wire feedstock, and then I'm machining in a way, right, so, but I think if you were just to, say, focus in on that material piece, maybe, maybe that's where you chunk it out. And then okay, now let's look at energy consumption. Let's look at, at the gas that's used, let's look at how much energy was needed to get the material in that format or in that, that type of feedstock, right. So you can, you can chunk it out. But that goes back to our earlier challenge of you got to be able to integrate all this stuff together as well. It's a double-edged sword for sure.

Stephanie Hendrixson 16:57

Yeah, so no one has really been able to kind of tie all of this together, but there are a lot of interesting research projects and reports that are coming out. I think we should get into some of the questions that we still need to answer after the break.

Related Content

How Additive Manufacturing Is Transforming EVs and Transportation: AM Radio #23

As 3D printing is adopted into the electric vehicle (EV) market, it is not just vehicles that are being reshaped. In this episode of the AM Radio podcast, we discuss additive manufacturing and the future of transportation.

Read More3D Printed Cutting Tool for Large Transmission Part: The Cool Parts Show Bonus

A boring tool that was once 30 kg challenged the performance of the machining center using it. The replacement tool is 11.5 kg, and more efficient as well, thanks to generative design.

Read More3D Printed Lattice for Mars Sample Return Crash Landing: The Cool Parts Show Bonus

NASA Jet Propulsion Laboratory employs laser powder bed fusion additive manufacturing plus chemical etching to create strong, lightweight lattice structures optimized to protect rock samples from Mars during their violent arrival on earth.

Read MoreIndyCar's 3D Printed Top Frame Increases Driver Safety

The IndyCar titanium top frame is a safety device standard to all the series' cars. The 3D printed titanium component holds the aeroscreen and protects drivers on the track.

Read MoreRead Next

EOS Conducts Sustainability Study for Eyewear Frames

Study results indicate 3D printed glasses have a higher wearing comfort, are more stable and sustainable than any other glasses.

Read MoreGetting to a Circular Model for Metal Powders Makes AM More Sustainable

6K’s UniMelt process offers efficiency and control in the production of metal powders for additive manufacturing. But more than that, it is a home for unused and oversized powder, metal scrap and more that can close the loop on metals.

Read MoreIs Recycled Metal Scrap the Future Feedstock of Choice for Metal 3D Printing?

MolyWorks is future-proofing the circular economy for metals with small-footprint atomization technology that converts metal scrap into additive manufacturing powder on the spot. But that's not the end of the story.

Read More

.jpg;width=70;height=70;mode=crop)