Markforged Expands Offerings with Larger 3D Printer

The FX20, Markforged’s largest and fastest 3D printer, is appearing at IMTS for the first time.

Share

Read Next

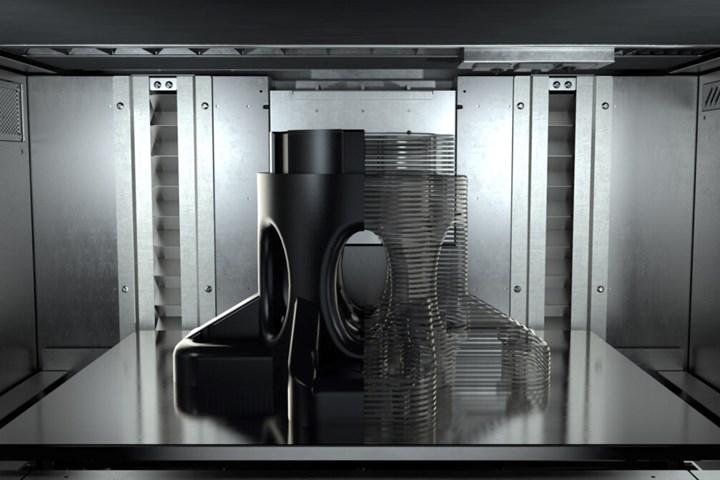

Markforged’s FX20 is the company’s largest (with a build volume of 525 × 400 × 400 mm), fastest and hottest (with a heated print bed that can reach 200˚C) machine. It will be on display in the company’s booth at IMTS.

Photo Credit: Markforged

As the market for 3D printing grows, so does the size of the 3D printers. Markforged’s booth features the FX20, its fastest and biggest machine (with a build volume of 525 × 400 × 400 mm) to date. “That's essentially our new top of the line,” explains Markforged product marketing manager Charles Lu. The fused filament fabrication (FFF) machine is equipped with a heated print bed that can reach 200˚C, enabling it to handle high temperature materials such as Ultem, as well as continuous fibers for added strength. The printer was announced last year and started shipping earlier this year, making this the first time the machine will be on display at IMTS.

Markforged is also exhibiting new materials, including a recently released thermoplastic polyurethane (TPU) for its composite desktop printers. This is a flexible material that is suitable for gaskets, baffles and robotic grippers. According to Lu, 3D printed TPU could unlock a new range of applications for users. “It's an entirely different set of problems that you can approach,” he says. And for its Metal X metal FFF machine, the company has a new version of its 17-4 PH stainless steel filament that is designed to significantly improve print quality over the previous version.

Related Content

-

Which AM Event at IMTS Is Right for Your Business? AM Radio #22

IMTS 2022’s two additive manufacturing-centered events are designed for different audiences.

-

Recapping the Additive Manufacturing Conference 2022: AM Interacts With Conventional Processes: AM Radio #26B

On the AM Radio podcast, impressions of this year’s Additive Manufacturing Conference at IMTS. A notable element this year was attention to AM’s impact on processes such as casting and machining

-

3 Points About 3D Printing Large Parts We Can Learn From the Lunar Habitat (Video)

Ingersoll Machine Tools describes the capabilities and promise of large-scale additive manufacturing as seen in the 3D printed sections of the Rosenberg Space Habitat.