The need for in-process monitoring of metal 3D printing processes is well-recognized but integration of cameras, sensors and systems to make this possible can be a hurdle. Madrid-based New Infrared Technologies (NIT) has developed a compact system for monitoring melt pools in directed energy deposition (DED) or laser metal deposition (LMD) 3D printing and laser cladding. The company’s Clamir system uses a high-speed infrared camera to continuously measure the melt pool in real time, and adjust the laser power to maintain the integrity of the print.

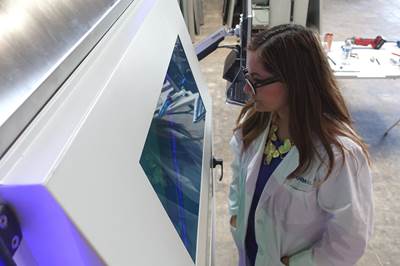

The Clamir unit is installed here on the printhead of a Laserline metal 3D printer. The hardware can be integrated into a number of DED-style machines.

Photo Credit: New Infrared Technologies

According to NIT business development manager Guillermo Guarnizo, the Clamir system’s objective is to maintain a melt pool that is “as stable as possible” by achieving a consistent meltpool width. Just that measurement alone is enough data for the closed-loop system to effectively alter the laser power in real time to keep the melt pool within established limits.

This is a change from how DED typically operates, with the laser under constant power. Over the course of the build, a consistent power setting can cause regions of the part to overheat and excess material to build up, leading to poor surface finish. Parts can end up deforming or needing additional postprocessing work to correct these issues. In cladding operations, constant laser power can even degrade the base material and prevent good adherence. Variable laser power based on real-time process monitoring can correct for these issues in situ, leading to better part quality and consistency.

The Clamir system consists of a medium wavelength infrared (MWIR) camera, processor and control installed in the 3D printer to monitor the melt pool on-axis; users can set the meltpool width and monitor their builds through integrated software. Photo Credit: New Infrared Technologies

Applying the Clamir system demands only a minimal hardware requirement. The solution consists of a camera, processor and control unit within a single housing that is mounted to the 3D printer’s laser head. As material is deposited, the middle wavelength infrared (MWIR) camera captures images of the melt pool at a rate of 1,000 frames per second. The width of the melt pool is measured with each image and compared to a value set by the user or automatically determined by the system; if the melt pool is found to be wider than expected, the Clamir control will reduce the laser power to prevent material overflow and heat deformation.

“It allows for printing of finer structures without building up excess material,” Guarnizo says, which is a benefit to downstream processes as well as 3D printing. According to the company, the use of the Clamir system helps to reduce defective parts and increase productivity, while also reducing CO2 emissions and saving energy.

See a side-by-side comparison of LMD with and without Clamir in this video, provided by Trumpf:

NIT won the Industrial & Enabling Tech category of the European Commission’s Innovation Radar contest in 2018 for Clamir and I3LasWeld, a similar platform for real-time classification of laser welding defects. Since then, New Infrared Technologies has worked with a number of equipment providers including Trumpf, Laserline and Precitec to incorporate Clamir into their equipment; the solution is also available to individual users. Most current customers are based in Europe, but the company is seeking to expand its presence in North America in 2023.

Related Content

Robot Deposition Makes Giant Industrial Mixer Blade: The Cool Parts Show Bonus

Wire arc additive manufacturing produces a large component formerly made through casting, and allows for redesign of its internal cooling geometry.

Read MoreBe a “DED Head?” AM Limitations – Eliminated

DED systems make it easier for manufacturers to integrate additive manufacturing by offering multiple capabilities as well as easy accessibility.

Read More500-Pound Replacement Part 3D Printed by Robot: The Cool Parts Show #50

Our biggest metal cool part so far: Wire arc additive manufacturing delivers a replacement (and upgrade) for a critical bearing housing on a large piece of industrial machinery.

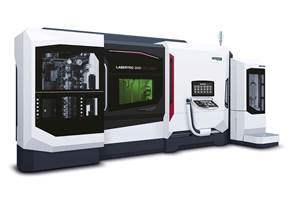

Read MoreDMG MORI’s Hybrid 3D Printer Offers 5-Axis Simultaneous Machining

DMG MORI’s Lasertec 3000 DED hybrid 3D printer offers process integration by combining laser deposition welding with 5-axis, turn-mill machining in one setup.

Read MoreRead Next

Robot Is Production Solution for Laser Metal Deposition

The move from prototyping to production might involve a move from machine tool to robot, but development work between Formalloy and the robot suppliers means the process and programming do not have to change.

Read MoreDirected Energy Deposition (DED) Error Turns Nozzle Into Chess Piece — AM: Why the Failure? #3

Chess pieces are often 3D printed as demo parts, but this one was an accident! What happened? The answer involves heat transfer.

Read MoreDirecting the Future of Laser Metal Deposition (LMD)

Formalloy is proving that LMD is for more than repairs and large parts. Fast deposition rates, fine detail capabilities and multimaterial support promise to change how parts are designed and made.

Read More

.jpg;width=70;height=70;mode=crop)