AM Investment Trends

At AMT’s MTForecast 2023 — an event which aimed to help manufacturers develop their business strategy — I discussed equity investments in additive manufacturing.

Additive manufacturing (AM) is seeing a high consistent annual growth rate of 14-15%. At AMT’s MTForecast 2023 — an event aimed to help manufacturers develop their business strategy — I presented on equity investments in AM, which provided the following insights.

Industry Size. The AM industry has grown from roughly $8.5 billion to nearly $14.5 billion between 2018 and 2022. This growth represents a compound annual growth rate of more than 14%. While $14.5 billion sounds like a large number for equipment, materials and services, AM still represents a small portion of durable goods manufacturing. For comparison, global machine tool sales revenue was $85 billion in 2021 — which was six times larger than the total addressable AM market.

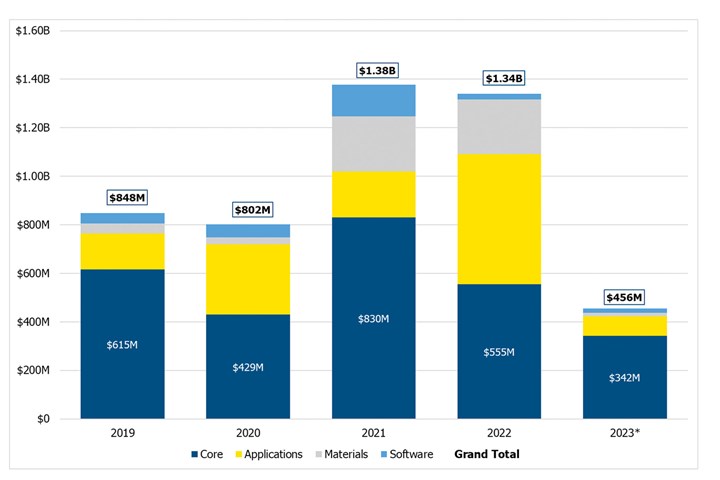

Venture Capital Investments

Venture capital investments can be sorted into four categories: core technology, applications, software and materials. Core technology represents process development and has remained the primary focus for venture capital investment. In 2022, investments in 3D printing applications reached $536 million, three times the amount from 2021. In contrast to the growth of recent years, total 2023 investment is projected to be down due to the broader economic factors and expectations. Higher interest rates and fears of recession have reduced the willingness to invest in AM. In 2023, venture investment in AM is projected to reach $570 million. Deal count is also lower, with a projected 55 in 2023, down from the 75 investment events in 2022.

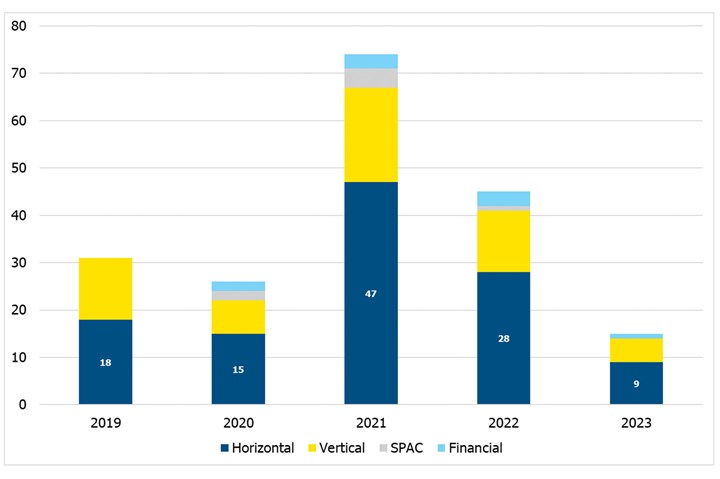

AM Mergers and Acquisitions (M&A)

Acquisitions can be categorized into four types of transactions: horizontal or vertical by relative position in the supply chain, special purpose acquisition company (SPAC) and financial. Horizontal and vertical transactions are strategic by nature and continue to represent most transactions in AM. When looking at the number of transactions by year, we can see that in 2021, many transactions that were delayed due to COVID-19 in 2020 went through and were finalized in 2021. The year 2022 represented a “return to the norm” for the industry, with 2023 showing a slower year for M&A activity. We now project there to be about 20 deals announced in 2023.

The Bet on Additive

While 2023 has had fewer total acquisitions than each of the last two years, large well-known companies continue to commit to AM technologies through minority investment and acquisitions. Most prevalent is Nikon, which has acquired Morf3D and SLM Solutions; invested in Hybrid Manufacturing Technologies and Optisys; and completed the rebrand of SLM into the entity Nikon SLM Solutions, putting its name directly on AM hardware. Despite seeing lower investment and M&A in 2023 amid economic uncertainty, brand name corporations and the collective investment in AM to date suggest a strong silver lining for the technology’s future.

For more industry intelligence, attend AMT’s MTForecast 2024 next October. For in-depth market research, contact AMT’s research team at research.amtonline.org. To read the full article and see the graphs, visit IMTS.com/AMTrends.

2023 data is represented through the end of August.

Read Next

3D Printing Brings Sustainability, Accessibility to Glass Manufacturing

Australian startup Maple Glass Printing has developed a process for extruding glass into artwork, lab implements and architectural elements. Along the way, the company has also found more efficient ways of recycling this material.

Read More4 Ways the Education and Training Challenge Is Different for Additive Manufacturing

The advance of additive manufacturing means we need more professionals educated in AM technology.

Read MoreAt General Atomics, Do Unmanned Aerial Systems Reveal the Future of Aircraft Manufacturing?

The maker of the Predator and SkyGuardian remote aircraft can implement additive manufacturing more rapidly and widely than the makers of other types of planes. The role of 3D printing in current and future UAS components hints at how far AM can go to save cost and time in aircraft production and design.

Read More