In article 1 of this series, Kevin Slattery and John Barnes lay out the basic framework for qualification. Subsequently, in article 2, we examine the environment of space and this is followed by heavy transportation in article 3. In each of these articles, spearheaded by the first, the authors elucidated that the process for qualification is essentially the same. The testing and types of testing may vary based on the expected environment but in all instances, the industry wants a repeatable and reliable process. Here, we dive into the requirements of military and defense applications for additive.

Defense and Why You Often Hear the Phrase “Weapons Systems”

The U.S. Marines are fond of saying, “Improvise, adapt and overcome all obstacles in every situation.” But what does this mean and what does it have to do with additive manufacturing (AM)?

Weapons systems in their basic forms are just that, systems. They have evolved to be capable of interoperability with other weapons systems and other military services, whether that be within a single defense organization or a coalition such as NATO (North Atlantic Treaty Organization).

Weapons systems are initially designed to meet an operational capability, for example, to deliver 12 troops to a destination 100 km away and land vertically. After accomplishing the task, the weapons system must meet a set of requirements that were developed with hundreds of years of experience in mind. Why? Because it won’t always be known whether it will be operating in a desert (heat and sand), the arctic (cold), near or in the ocean (wet and corrosive), so it must meet all these established requirements.

The weapons system will function for an intended lifetime; but it is not uncommon to see some of these platforms serve much longer than anticipated and others are given extended life via upgrades and extensive maintenance.

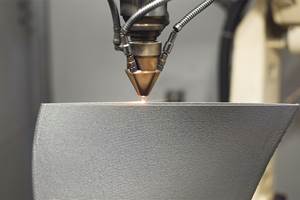

When we think about AM, the manufacturing process must be repeatable and reliable to even be considered for manufacturing parts for a weapons system. We ultimately cannot conceive all the scenarios it could be used for, so instead we must be able to verify the parts that are manufactured via AM to determine whether they can meet minimum thresholds — full stop. When we qualify a part, we also qualify the process, the operator and the facility where it was manufactured.

Why Is Defense Manufacturing Different?

The loss of the USS Thresher on April 10, 1963, was a watershed moment in the history of submarine disasters. The Thresher was a nuclear-powered attack submarine and its tragic sinking claimed the lives of all 129 crew members on board. The subsequent investigation revealed that a piping failure in the engine room led to a cascading series of events, ultimately causing the submarine to exceed its maximum depth and subsequent implosion.

This disaster prompted a comprehensive reevaluation of submarine safety and design. In response, the U.S. Navy implemented stringent technical requirements, rigorous testing protocols and enhanced safety measures to prevent such catastrophic incidents from occurring again. Contrary to the perception that stringent technical requirements are synonymous to slow, antiquated processes and timelines, the nuclear submarine community is actively engaged in ensuring technical requirements are right-sized and forward-leaning.

The drive for strict technical requirements in submarine design and construction stems from a deep commitment to the safety of naval personnel and the protection of critical assets. The loss of the Thresher highlighted the inherent risks associated with underwater operations, especially given the demanding conditions of deep-sea exploration and warfare. The cost of submarines, both in terms of financial investment and human lives, underscores the delicate balance between risk and reward.

While submarines are invaluable assets for national security, their complexity and the harsh operating environments they function in demand uncompromising technical standards to mitigate potential disasters. The stringent requirements and approval process imposed on submarine development aim to uphold the highest standards of safety and reliability, acknowledging the inherent risks of undersea operations while ensuring the rewards of naval superiority are achieved without unnecessary sacrifices.

The saying, “complex systems fail in complex ways,” is highlighted by the USS Thresher example. Manufacturing for defense applications is surprisingly complicated by several factors that may not be apparent at first glance. All the weapons systems are complex, many of which become more complex as time goes on.

The Department of Defense (DOD) expects all materials to function to specifications, at which time calculations can be made for each new mission requirement. The most challenging missions could involve the worst service conditions using platforms that are operating beyond their initial design life due to service life extensions. While there are civilian equivalents of planes, ground vehicles or ships, defense requirements drive design and material selection to push manufacturing into new and challenging spaces.

Defense Requirements

Another aspect of defense manufacturing is the defense-specific requirements for service. Pending if this is a C-130 transport, an M1 Abrams tank or a Virginia-class submarine, there will be requirements for blast or shock and ballistic loads that have little crossover to civilian components.

Additionally, these platforms must survive the loads across a large range of service conditions from the high atmosphere for aircraft, the depths of the oceans for our submarines or extreme hot and cold climates of any potential conflict zone. This pushes the use of higher-performance materials which have challenging manufacturing considerations.

For the warfighter who operates the aircraft, ground vehicle or submarine in whatever variant, for whichever mission, their objective is the mission’s success. There cannot be any concern as to whether the weapons system is up for the challenge because it is using AM parts. The design authority ensures the performance of the system is maintained. The customer oversees this as the verifying entity that certifies the platform for service.

It Starts With The Part

When introducing a new manufacturing method and design (as these typically go hand in hand), the part must meet or exceed the requirements. This could be met through analysis if there is sufficient data on the design an or manufacturing method from other parts or other industries and applications.

When the process is newer and little data exists, the data will need to be generated and would follow the “building block” process, starting with coupons and work up to full-size testing if required. This process is designed to build trust in the new component, design or manufacturing process and it follows the System Engineering “V” figure.

If little to no data exists, more testing is certainly required. This process is designed to build trust in the new component, design, or manufacturing process and to do so the System Engineering “V” (depicted above) is followed. Photo Credit: The Barnes Global Advisors

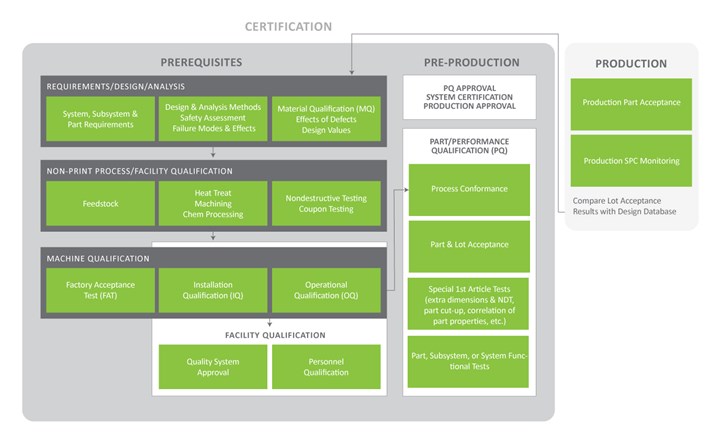

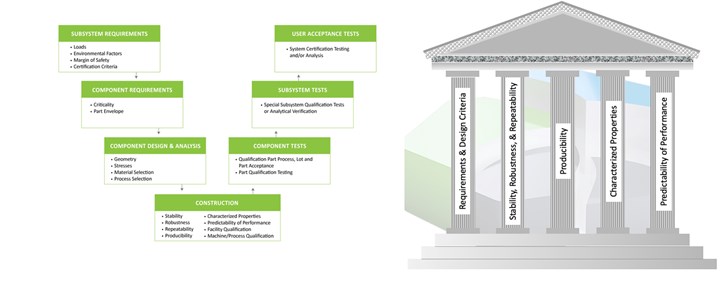

Naturally, to build trust in the part, we must also ensure we have trust in the machinery, the operator and the facility that those elements operate within. As noted in the first article, there is the The Barnes Global Advisors’ (TBGA’s) AM Qualification Framework to use as an illustration of where we are in the process.

This chart outlines the guidelines of the TBGA AM Qualification Framework to ensure trust in the machinery, the operator, and the facility that those elements operate within when utilizing additive manufacturing for defense. Photo Credit: The Barnes Global Advisors

Failing Is Inevitable

The question is: How will it fail and can we live with the outcome? As the second article in our series with NASA eloquently said, “Can we trust this system to perform without a doubt?” Defense systems are similar.

What are the consequences of the failure of that part? Detailed analyses are completed to answer these questions and it does matter whether the system operates in the air, underwater or on the ground just as much as it matters whether the loss of the part in question could result in the loss of the entire system.

Soldiers from 1st Battalion, 6th Infantry Regiment, aboard an M1 Abrams tank to provide security during a simulated battle. Photo Credit: Sgt. Todd Robinson

For instance, if a noncritical component of the M1 Abrams tank (depicted in the image to the right) has failed, the system is still mission-capable while the part is ordered. But if a mission-critical component fails, such as the engine, then the vehicle is non-mission capable and readiness is negatively impacted.

If such a part fails during combat, then it puts the mission and or the soldiers' lives in danger. Thus, the importance of both having supply chain availability of parts, especially mission-critical parts and the inherent reliability of those parts ensured by design, manufacturing and testing requirements is crucial.

Improving, Adapting and Overcoming

We’ve mostly discussed the ideal case where we design for that known condition, where we have some design flexibility to produce the part and install it into the system on the assembly line.

The fun begins once the system is fielded, as it must then be sustained. Maintainers have a demanding role in finding spare parts, creating repairs, and generally adapting and overcoming wherever the system is and whatever logistical challenges they face.

These challenges can be unique to weapons systems. Compared to any commercial-world equivalent, the systems don’t see as much time in service and will be in service for generations of soldiers, sailors, marines, airmen and women.

Sourcing spare parts is a challenge when the quantity is low and the mix is high. Traditional manufacturing has evolved over the decades and as legacy manufacturing methods get replaced with better, newer methods, the parts coming from those methods must be proven to meet or exceed the requirements.

The manufacturer of the part might have little insight into where the part is going, but the design authority and System Program Office (SPO) do. They all must work together to ensure the machinery produces a part that can seamlessly fit into the supply chain. After all, the 3D printer only generates a shape. It becomes a part later on in the process.

Adapt: We Have to Deal With the Reality of the DIB

Developing the next generation of defense while sustaining the current force is demanding on the defense industrial base (DIB). Increasing system service life (such as the previously discussed C-130 or M1 Abrams tank), the number of variants of a platform (over 70 variants of the C-130 and 20 of the Abrams), changing the performance requirements to meet new and evolving threats, and the increasing complexity for both the current platforms and those in development is necessitating a larger defense base with increasing design and manufacturing flexibility.

Today, supply chains are stretched and the supply and demand situation seeks efficiency with high volumes of the same design. Sadly, the pressures listed above drive to a high mixture of low volume quantity parts. When this eventuates, lead times are excessively long and prices soar higher.

The DOD does not have the time or resources needed to requalify every part within the millions of parts in the defense inventory. Efforts are needed to qualify the equivalence or interchangeability of AM parts to enable the DOD to accept AM production.

Overcome: The Excessive Lead Time

One such example of this scenario are parts made of castings and numerous weapons systems being negatively impacted through long delivery times, which then negatively impact their mission-ready capability. Many entities, such as the Submarine Industrial Base (SIB) are assessing the viability of using AM to meet or exceed the requirements of the original parts.

Matt Sermon, executive director of strategic submarines program executive office (PEO SSBN) recently said, “Eighty percent reduction in schedule for components that we need in shipyards, for components that we need in new construction, is not unrealistic.” This is largely due to the loss of domestic manufacturing capability over the past several decades.

From 1979 to 2017, the US lost 7.1 million manufacturing jobs, equivalent to 36% of the workforce and there are 25% fewer manufacturing firms and plants than there were in 1997.

Unfortunately, defense production is dependent upon domestic manufacturing sources and these changes to DIB are providing a new threat that we, as a nation, must overcome. The DOD is investing in new infrastructure to regrow the traditional DIB while also expanding through enabling and adopting new manufacturing technologies.

Additive manufacturing is needed to augment and broaden the industrial base to provide new means of production.

Improving: Using AM in the Field

Not only can AM yield benefits to the DIB, it also has huge potential to provide new modalities of improvisation. Over the past several years, the services have been introducing forward-deployed advanced manufacturing cells. These cells are meant to address the challenge of manufacturing at the point of need versus waiting for critical supplies through long logistic tails.

There are examples of the Army replacing a part that would take 126 days for shipping that was made overnight. The Navy and Marine Corps have developed metal AM systems. Most recently, the DOD has deployed SPEE3D’s cold spray additive manufacturing systems to Ukraine.

These systems enable development of replacement parts or rapid modification to adapt or improvise to meet an unforeseen challenge. While these technologies are new and not yet qualified to produce every part, not all parts are critical and do not require rigorous qualification and certification to be of value to the warfighter.

The risk of using AM parts must be balanced against the benefit of its use, so the Services are generating guidance on where AM parts are acceptable and what the qualification requirements are for various levels of criticality.

Trust Me. I Know What I’m Doing.

As Ronald Reagan said, “Trust, but verify.” Our Qualification Framework works in a similar fashion. Once proven to be acceptable, we then constantly verify the Defense Industrial Base (DIB) is manufacturing parts that go into systems and can meet the system performance supported by the data that was originally generated.

Another Applicable Quote Incoming

We are setting ourselves up with a Top Gun chestnut, “This is a target-rich environment” to choose some quotes to inspire our industry.

The challenges are many, but the question is whether the destination is worth the journey. From John F. Kennedy’s inspirational words as we entered the Space Race, he challenged the country to get to the moon in less than 9 years.

Suppose we can be so bold as to adopt President Kennedy’s words for our scenario where our mission is to ensure that additive manufacturing is part of the manufacturing arsenal and where factories are clean and safe. In that case, the people want to be there and we don’t need to make excuses for lack of commercial merit, data, etc. This is a mission worth working for. Kennedy went on to say that we choose to do these things, “Not because they are easy, but because they are hard.”

And when the journey is hard, most will not follow.

Let’s Get Moving

Thomas Edison noted this in his day and it is still rings true today, “Opportunity is missed by most people because it is dressed in overalls and looks like work.”

Understanding AM and how it works, what it can do, and where it opens design opportunities can pay off even in very demanding commercial situations, because it improves the system. Ultimately, it isn’t about the printer. The printer is an enabler sure, but if you want to get a part qualified, and in revenue service, attention is on the overall process. The printer must serve to work in a repeatable, reliable manner.

Investing in AM is worth it. The key word here is investing. A lot of what we see today is shortsighted and not looking at the long game. Manufacturing is great for economies and an essential part of the Defense Industrial Base.

This isn’t lip service or hype, it is a major recommendation coming from the DOD in response to Executive Order 14017. Investing in manufacturing is investing in your country, your allies and ultimately your way of life. It’s also an investment in your neighbors, whether they work in a factory, as an accountant, marketer or medical professional as manufacturing dollars stay regional.

Investing in defense is money well spent. After all, it is called defense, not offense. The goal is deterrence. U.S. Army General Mark Milley said, “The only thing more expensive than deterrence is actually fighting a war, and the only thing more expensive than fighting a war is fighting one and losing one.”

As we have noted, the process of qualification is unchanged by any advanced manufacturing method, but the testing and types of testing will impact how much data is required to obtain qualification. In this article, we’ve highlighted why defense requires the testing and data to be qualified.

AM is one of several forms of advanced manufacturing and the trend in advanced manufacturing is complexity and integration — it’s a system of systems. Complexity requires a team and an ecosystem. Ecosystems are inherently strong because they are businesses that rely on each other, but they also rely on each business to invest and optimize. It is the very epitome of the USMC mantra, “Adapt. Improvise. Overcome.”

Related Content

From Polymer Tooling to Metal Production Via 3D Printing

As Azoth has adopted new additive manufacturing technologies, its work has transitioned from tooling to production parts for automotive, medical and defense.

Read MoreEOS Works With Phillips Federal, Austal USA to Develop CopperAlloy CuNi30 for US Navy Submarine Industrial Base

Using the copper-nickel alloy in combination with EOS’ platforms offers new design and production capabilities for U.S. Navy submarines, while also enabling the agency to limit global supply chain disruption because parts can be produced regionally, locally and on-demand.

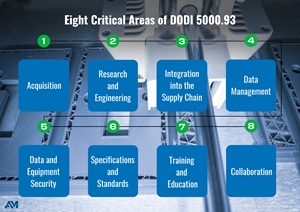

Read MoreDOD Drives Transformation with New AM Policy

The U.S. Department of Defense published DODI 5000.93, a comprehensive plan for implementing additive manufacturing among military services.

Read MoreDefense Department Looks to Additive Manufacturing to Propel Hypersonic Systems

The DoD is requesting prototype solutions for its Growing Additive Manufacturing Maturity for Airbreathing Hypersonics (GAMMA-H) challenge as part of the department’s ongoing efforts to expand manufacturing processes for intricate hypersonic weapons parts.

Read MoreRead Next

A Framework for Qualifying Additively Manufactured Parts

A framework developed by The Barnes Global Advisors illustrates considerations and steps for qualifying additively manufactured parts, using an example familiar to those in AM: the 3D printed bottle opener.

Read MoreAdditive Manufacturing in Space: Failing Upward

Not all 3D printed parts destined for space need to adhere to the standards of human space flight. Yet all parts made for space programs require some type of qualification and certification. NASA and The Barnes Global Advisors explore Q&C for these parts.

Read More4 Ways the Education and Training Challenge Is Different for Additive Manufacturing

The advance of additive manufacturing means we need more professionals educated in AM technology.

Read More