Additive Manufacturing Competency Center Open for Training

The UL AMCC trains manufacturing professionals to safely and effectively use additive manufacturing technologies.

Share

Read Next

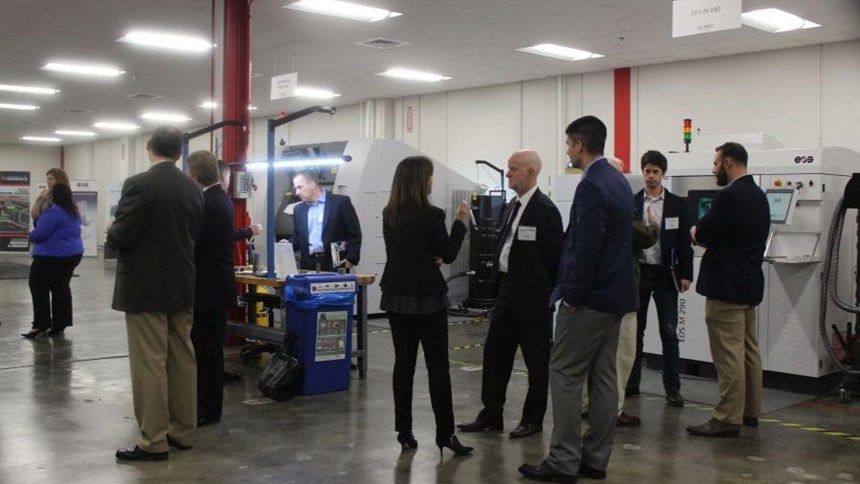

The UL Additive Manufacturing Competency Center (AMCC) held an open house and ribbon cutting ceremony last Tuesday to commemorate its grand opening. The center, located on the University of Louisville (UofL) campus, is the result of a public-private partnership between the university and the safety science organization Underwriters Laboratories (UL) to provide holistic training in additive manufacturing.

In conjunction with the event, UL and EOS announced a memorandum of understanding in which the companies will collaborate to provide training, advisory services and safety management to EOS customers. EOS is one of a number of equipment suppliers who work with and support the UL AMCC.

The UL AMCC was first announced in 2015, and has become reality in less than one year—the first classes began there in December. Despite its University of Louisville location, the center’s students come primarily from industry. Most are employees of manufacturers that own additive manufacturing equipment, though that’s not a requirement to enroll.

Three different course tiers are offered. Tier 1 includes foundational classes that introduce students to the basics of 3D printing and additive manufacturing, and is suitable for beginners or those considering the purchase of an AM machine. Tier 2 offers more technical training including classes in AM design, quality and safety, and materials and processes. Tier 3 provides advanced training in metal part production.

Most courses are hands-on and class sizes are kept small, usually eight to 10 students, to ensure that the quality of instruction remains high and that individual questions and concerns can be addressed, says Ed Tackett, director of educational programs. UL has developed a formal additive manufacturing certification process for students who demonstrate required competencies.

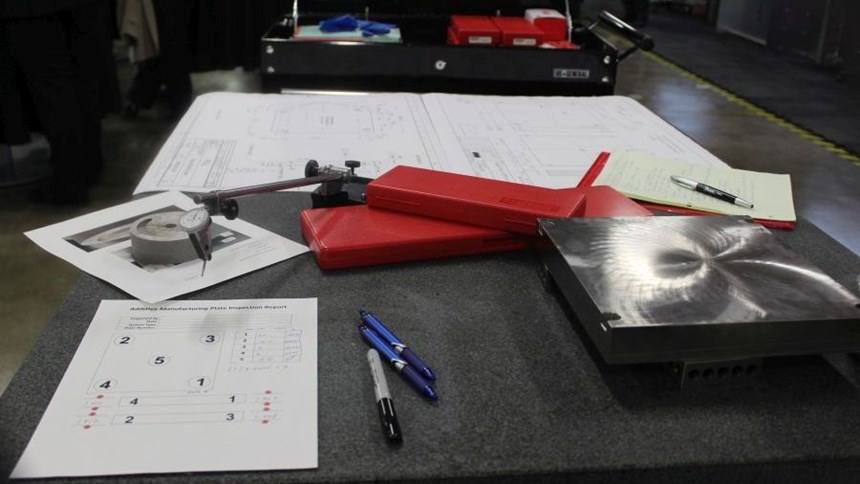

The UL AMCC is set up to take enrolled students from the beginning to the end of the metal additive manufacturing process, from programing to building to finishing. The facility boasts a computer lab, two selective laser melting machines, and a range of postprocessing equipment including a depowdering station, a band saw for cutting parts off of build plates and a shot peen machine.

While the equipment in the AMCC is not representative of every option for metal additive manufacturing (many facilities use wire EDM to remove parts from the build plate, for instance) it has been chosen to be representative of “shared” equipment—that is, machines that established manufacturers might already have at their disposal, says Paul Bates, lead AM development engineer at UL AMCC. Being able to use existing equipment for additive processing is generally more cost-effective for manufacturers, especially those just starting out in the additive space.

But another critical part of the center’s mission is to open students’ eyes to equipment and systems they may not know they need, especially in the area of safety. Personal protective equipment (PPE) such as masks and fire-retardant hoods hang prominently on pegs near the additive machines, and a monitor on one wall tracks the amount of oxygen in the room. Measures such as these keep the center and its students safe, but also serve as a model for how to properly set up a metal additive facility.

Beyond the value of the services and courses it provides, the new center is also a key “part of the ecosystem” being built at UofL, according to Dr. John Usher, acting dean of the JB Speed School of Engineering. The UL AMCC is currently located at the edge of campus, adjacent to the UofL Engineering Garage, a maker space for engineering students, and next door to FirstBuild, a microfactory run by GE Appliances and Local Motors. But this is a temporary location. In the near future, the UL AMCC and its neighbors will relocate to a 40-acre plot of land behind the engineering school, the future site of the Institute for Product Realization (IPR).

The IPR will be a collaboration of key organizations at the University of Louisville, connecting the UL AMCC, Rapid Prototyping Center (a facility for applied AM research, prototyping and short-run production) and others with university students, faculty, researchers and companies. The institute will offer design, prototyping, testing and production services to help develop and bring products to market faster. The UL AMCC is expected to move to its permanent home within the IPR in 2017.

Related Content

America Makes Announces 3 Project Calls Totaling $4.6 Million in Awards

Project opportunities focus on utilizing additive manufacturing to address immediate and mid-term needs of the domestic supply chain.

Read MoreLittle Wins Create Value in Additive Manufacturing

How to create value with a multilevel approach to additive manufacturing.

Read MoreHow to Pursue a Career in Additive Manufacturing

AM professionals are in demand as 3D printing matures and advances. But what skills are hiring manufacturers looking for? How can applicants prepare? And where can you find relevant job listings?

Read MoreAM Workshops: The 3D Printing Conferences at NPE and IMTS 2024

We are presenting half-day conferences on additive manufacturing at both of the two largest manufacturing events in North America this year. Join us!

Read MoreRead Next

6 Things I Learned about Metal 3D Printing at the AMIST

I sat in on one and a half days of a five-day class offered at the Additive Manufacturing Institute of Science and Technology (AMIST) in Louisville. Here’s just some of what I learned.

Read MoreAt General Atomics, Do Unmanned Aerial Systems Reveal the Future of Aircraft Manufacturing?

The maker of the Predator and SkyGuardian remote aircraft can implement additive manufacturing more rapidly and widely than the makers of other types of planes. The role of 3D printing in current and future UAS components hints at how far AM can go to save cost and time in aircraft production and design.

Read MoreHybrid Additive Manufacturing Machine Tools Continue to Make Gains (Includes Video)

The hybrid machine tool is an idea that continues to advance. Two important developments of recent years expand the possibilities for this platform.

Read More

.jpg;width=70;height=70;mode=crop)