Phase3D’s Early Adopter Program for Real-Time AM Part Quality Inspection

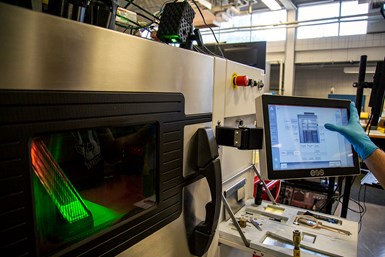

Company says 3D printing in-situ inspection system detects defects in real-time, enabling users to fully monitor additive manufacturing operations for both laser powder bed fusion (LPBF) and binder jetting processes.

Phase3D is launching an Early Adopter Program for its Project Fringe, giving companies an opportunity to access the company’s advanced in-situ inspection system for additive manufacturing (AM). This real-time quality monitoring system is said to go beyond simple monitoring due to its in-situ inspection of each powder layer in the 3D printing processes.

Project Fringe, Phase3D’s flagship system, is an inspection tool that uses structured light to objectively detect and classify print anomalies that can lead to part defects. The company says the system produces quantitative height mapping and is the only system available that can measure out-of-plane surface anomalies in real time for both laser powder bed fusion (LPBF) and binder jetting processes.

“At Phase3D, we've created a real-time inspection system using rapid height measurement technology to detect and classify process anomalies during 3D printing,” says Niall O'Dowd, Ph.D., Phase3D founder and CEO. “Our goal is to reduce the cost per part in AM by shifting the paradigm from in-situ monitoring (i.e., identifying outliers) to in-situ inspection, a repeatable quality and certification system based on direct measurement.”

It is said the structured light technology can measure any powder-based AM process. The real-time data creates detailed measurements for where and when a print anomaly occurs. The system presents data in 3D, enabling users to see a multitude of print anomalies in real-time.

The program is available for inquiry now, but has limited space availability. Program participants will have early access and reduced pricing structures for commercial installation of Project Fringe. The program is targeting production-oriented businesses that have in-house laser powder bed fusion (LBPF) or binder jetting systems.

To date, Phase3D is compatible with 3D printers such as the EOS M 290, ExOne/Desktop Metal Innovent, Concept Laser M2, Renishaw AM400 and DMG MORI LASERTEC 30. Additional 3D printers can be retrofitted based on individual customer demand.

The company says the Project Fringe technology has been validated through investments and partnerships from leading organizations, including a two-year funded contract with the Air Force Research Lab and Oklahoma City Air Logistics Complex. It also has a cooperative agreement note for a one-year development partnership at NASA’s Marshall Space Flight Center. The company recently completed a one-year technical collaboration and is now moving to phase II with Oak Ridge National Laboratory; as well as a two-year cooperative research and development agreement with Argonne National Laboratory. Finally, Phase3D established a two-year fellowship from Oak Ridge Institute for Science and Education.

“After validating the technology with partners at NASA, the Air Force Research Lab and several Department of Energy labs, we are excited to unveil the Early Adopter Program,” O’Dowd says. “We are offering our inspection tool to manufacturers for a greatly reduced software fee, in exchange for data exchange.”

The Early Adopter Program includes hands-on time with the Phase3D team to initialize Project Fringe on-site, retrofit installed printers, and keep up and running via a monthly software license. The hardware and software package will attach to any powder bed-based 3D printer and detect defects in real-time throughout all print cycles.

Phase3D was launched in fall 2021 as a spinout from the University of California and is now focused on advancing in-situ monitoring for AM in production environments.

- Watch this 101 video on “What Is Laser Powder Bed Fusion (LPBF)?” to learn why LPBF is likely the most widely used metal AM process. Here is how it works, including benefits, issues to consider and applications for this 3D printing technology.

- Here is a look at how binder jetting works and its benefits for additive manufacturing. This 101 article gives an overview on “What Is Binder Jetting?” — describing a process that requires no support structures, is accurate and repeatable, and is said to eliminate dimensional distortion problems common in some high-heat 3D technologies.

Related Content

Formnext 2022: Ceramics, Robots and Other Perspectives From Near and Far: AM Radio #30

The 2022 edition of Formnext revealed more options and applications for 3D printed ceramics, anticipation of coming automation, established companies entering AM and more. Two editors — one present at the show, and one observing from a distance — compare notes in this episode of AM Radio.

Read More8 Cool Parts From RAPID+TCT 2022: The Cool Parts Show #46

AM parts for applications from automotive to aircraft to furniture, in materials including ceramic, foam, metal and copper-coated polymer.

Read More10 Important Developments in Additive Manufacturing Seen at Formnext 2022 (Includes Video)

The leading trade show dedicated to the advance of industrial 3D printing returned to the scale and energy not seen since before the pandemic. More ceramics, fewer supports structures and finding opportunities in wavelengths — these are just some of the AM advances notable at the show this year.

Read More3D Printing Brings New Possibilities for Manufacturing With Ceramics: AM Radio #27A

AM expands the opportunities for ceramics. On the AM Radio podcast, a discussion of various 3D printing processes making use of ceramic material, and various new applications for ceramics that are developing as a result.

Read MoreRead Next

4 Ways the Education and Training Challenge Is Different for Additive Manufacturing

The advance of additive manufacturing means we need more professionals educated in AM technology.

Read MoreHybrid Additive Manufacturing Machine Tools Continue to Make Gains (Includes Video)

The hybrid machine tool is an idea that continues to advance. Two important developments of recent years expand the possibilities for this platform.

Read More3D Printing Brings Sustainability, Accessibility to Glass Manufacturing

Australian startup Maple Glass Printing has developed a process for extruding glass into artwork, lab implements and architectural elements. Along the way, the company has also found more efficient ways of recycling this material.

Read More