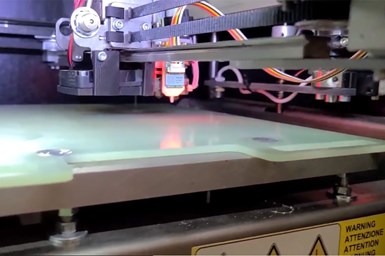

OnAdditive Offers Aftermarket Upgrade for 3ntr A2, A4 3D Printers

The enhanced capabilities include a new control system that gives the printers increased printing speeds, improved quality, automatic bed leveling and various other user-centric improvements.

Share

Read Next

OnAdditive — a manufacturing, engineering and design company — now provides aftermarket upgrades compatible with the 3ntr A2 and A4 3D printers to enhance the capabilities and performance of these systems. The company says it is supercharging these printers with a new control system, giving them increased printing speeds, improved print quality, automatic bed leveling and various other user-centric improvements.

These upgrades also demonstrate the company’s commitment to promoting a circular economy and minimizing environmental impact through reducing e-waste, an effort driven by the company’s belief in sustainability and environmental responsibility.

OnAdditive recognizes the need to transition from a linear economy, where materials are used and discarded, to a circular economy, where resources are repurposed. With this in mind, the aftermarket upgrade to the 3ntr A2 and A4 has incorporated features that turn them into better, faster, modern systems that can provide value for another 5 to 10 years.

The company says the 3ntr A2 and A4 printers have very good mechanical bones. The upgrades include modern electronics enhancements that take the printers to a new level.

The v1 feature release includes:

- Powerful new motherboard and motion control system that make printer quieter, cleaner and faster

- 5-inch touchscreen on the printer has intuitive modern interface with real-time print control

- Built-in web server offers customizable web user interface which supports user macros, custom themes and more

- Input shaping and resonance compensation enable smoother and faster prints

- Automatic bed leveling offers faster printing directly onto a provided G10 build plate

- All metal U.S. heaters are more robust for handling higher temperatures, making it longer lasting and less expensive

- One-year machine warranty

- Supported slicers include KISSlicer and Cura (other slicers can work with the printer)

Future releases include:

- Coolant temperature monitoring so users know coolant level before a failure occurs

- Power loss print recovery enables the print to continue after a power loss

- AI camera for part failure detection

OnAdditive will also offer the upgrade for new 3ntr A2 and A4 printers. The company is considering potential upgrades with other OEMs’ older industrial systems whether they are discontinued or not, or working or not.

Fully Open Industrial Systems

The upgrades offer users more control of their printer and their investment. The company says this is a first for the world of industrial grade printers and believes 3D printer manufacturers should follow this lead. The aftermarket upgrade is immediately available for any age A2 and A4 (working or not) in both the U.S. and the EU with support for the upgrades in both geographic areas.

OnAdditive is a research, development and services company with a background in manufacturing, engineering and design. It offers commercial 3D printing products and services. It is a former authorized reseller of 3ntr printers and says it is deeply engrained in 3D printing technology for both polymers and now DED-arc Hybrid Manufacturing.

Related Content

-

The AM Ecosystem, User Journeys and More from Formnext Forum Austin: AM Radio #43

Sessions and conversations at the first U.S. Formnext event highlighted the complete additive manufacturing ecosystem, sustainability, the importance of customer education, AM user journeys and much more.

-

Additive Wins on Cost, Plus Process Monitoring and More from RAPID + TCT 2023: AM Radio #38

Additive manufacturing is finding success as a cost-effective manufacturing method. New options for process monitoring are now available. DED is getting more precise. 3D printed chairs! What we learned and observed at RAPID + TCT 2023.

-

Evaluating the Printability and Mechanical Properties of LFAM Regrind

A study conducted by SABIC and Local Motors identified potential for the reuse of scrap reinforced polymer from large-format additive manufacturing. As this method increases in popularity, sustainable practices for recycling excess materials is a burgeoning concern.