Formlabs Dental, Medit Collaborate to Streamline Chairside 3D Printing

Combining their technology is said to enable clinicians to easily 3D print dental components with greater speed and efficiency through a simplified in-office workflow.

Share

Read Next

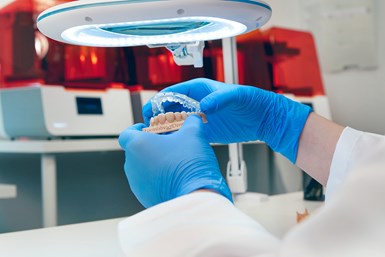

Formlabs’ PreForm app helps to prepare dental CAD designs for quick, convenient printing on Formlabs printers. Photo Credit: Formlabs

Formlabs is partnering with Medit to make chairside 3D printing accessible and approachable for all dental practices. Medit Link users can now download Formlabs’ PreForm app — a software integration that helps to prepare dental CAD designs for quick, convenient printing on Formlabs printers — directly from Medit Link.

The companies say that combining their powerful, intuitive technology enables clinicians to easily 3D print dental components with greater speed and efficiency through a simplified in-office workflow.

“Formlabs Dental is expanding access to 3D printing, and doing so requires partnering with industry leaders like Medit to address barriers to adoption in the dental industry,” says Dávid Lakatos, Formlabs chief product officer. “Together, we’ve created a complete chairside workflow that addresses these barriers to make the technology more accessible, with the ultimate goal of unlocking the benefits of dental 3D printing for both providers and patients.”

With Medit intraoral scanners, it is said dental professionals can scan a patient’s teeth, and then simply and easily convert scans into 3D printed models and appliances with a Formlabs Form 3B+ printer. This partnership is said to build on the success of Formlabs Dental, which has supported digital dentistry adoption with validated workflows, its biocompatible portfolio (including resins such as Permanent Crown and Temporary CB) and Formlabs’ PreForm software.

Dental professionals can utilize this workflow with Medit’s i500 and i700 intraoral scanners to add 3D printing in a reliable, easy-to-integrate way to their workflows, without extensive training and costs, the company says.

“The integration of Formlabs and Medit combines best-in-class 3D printers with the industry's fastest intraoral scanner. This will inevitably bring about great synergy, resulting in easier access to a complete chairside solution,” says Inhaeng Cho, Medit chief strategy officer.

Related Content

-

Ice 3D Printing of Sacrificial Structures as Small as Blood Vessels

Using water for sacrificial tooling, Carnegie Mellon researchers have created a microscale method for 3D printing intricate structures small enough to create vasculature in artificial tissue. The biomedical research potentially has implications for other microscale and microfluidics applications.

-

ActivArmor Casts and Splints Are Shifting to Point-of-Care 3D Printing

ActivArmor offers individualized, 3D printed casts and splints for various diagnoses. The company is in the process of shifting to point-of-care printing and aims to promote positive healing outcomes and improved hygienics with customized support devices.

-

From Polymer Tooling to Metal Production Via 3D Printing

As Azoth has adopted new additive manufacturing technologies, its work has transitioned from tooling to production parts for automotive, medical and defense.

.png;maxWidth=300;quality=90)