Castor Offers Free Trial Version of Automatic Part Identification Software

Castor is offering a free trial version of its industrial manufacturing software for automatic part identification, enabling potential customers to explore the software’s capabilities.

Share

Read Next

Castor, an industrial manufacturing software for automatic part identification, is now available for a free trial. The company is offering the free trial version to enable potential customers to explore the software’s capabilities.

The software solves the challenge of identifying where, when and how to utilize the benefits of additive manufacturing (AM) by automating the process of screening parts and highlighting the parts that make a good business case for AM.

Automatically Identify Opportunities For Additive Manufacturing

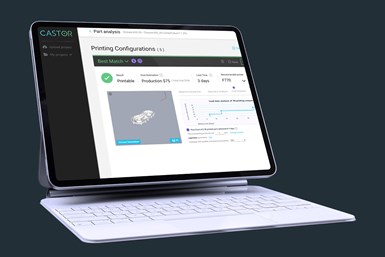

With Castor’s free trial, users have the ability to analyze and determine the AM potential and benefits of a selected part. This opportunity enables users to understand how the software’s analysis can empower them to make informed decisions based on a deep analysis, which considers material properties, cost-effectiveness, digital supply chain benefits and environmental benefits.

The software also recommends optimal combinations of 3D printers and printable materials based on specific part requirements. It estimates production costs, lead times and Co2 emission savings, and gives a visualizing break even point between the manufacturing methods. Given the insights provided by the software, users can confidently select the right technology with the right material to realize the value that AM offers.

Accelerating the Transition to AM

The software’s automatic process enables engineers to identify suitable parts for AM in seconds, thereby accelerating the evaluation process and reducing time-to-market for AM projects. “Our mission is to help every engineer reduce the time and effort required to identify the opportunities for Additive Manufacturing,” says Omer Blaier, Castor co-founder and CEO. “Through the Trial, we want to enable every engineer experience the value of our software firsthand.”

Castor’s Full Version Identifies Suitable Parts for Additive Manufacturing at Scale

The process of selecting the optimal parts for 3D printing out of thousands of parts can be time-consuming. Castor’s software has the ability to analyze thousands of parts at once and identify the opportunities where AM makes sense — from a technical, economical and sustainable point of view. The software provides a wide range of advanced capabilities and offers multiple tools, both for new adopters and for AM experts. It enables users to improve efficiency by finding weight reduction and part consolidation opportunities. The advanced capabilities include the ability to run a quick assessment of a part’s likelihood to failure, using a unique, tailored to AM, finite elements analysis.

For more details on Castor software, read this AM article.

Related Content

-

Lightweight Components: A Paradox When Machining

Today’s computer software can just as easily generate lightweight shapes for subtractive processes as it can for additive ones, but it increases cost and waste to make them.

-

Spherene Creates Metamaterial with Geometry Derived from Spheres

An algorithm developed by Spherene Inc. generates Adaptive Density Minimal Surfaces (ADMS) as a self-supporting infill strategy that can be used to reduce mass and manage material properties in 3D printed parts.

-

To Scale Additive Manufacturing, Separate Design and Production

Spokbee’s online marketplace is designed to ease the launch and sale of customizable, 3D printed products. Its flexibility comes from cloud-based CAD and a distributed network of service bureaus for production.