AMALLOY Is UAE’s First Locally Developed 3D Printing Alloy

The Technology Innovation Institute says its AMALLOY aluminum alloy powder registers 33% greater strength without compromising on ductility when compared to commercially available AlSi10Mg alloys.

Share

Read Next

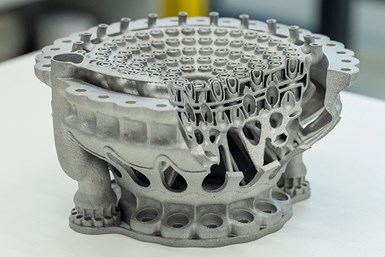

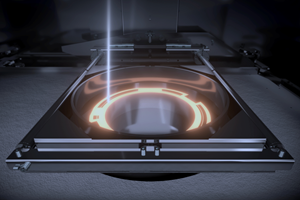

AMALLOY is a new aluminum alloy powder developed by the Technology Innovation Institute (TII) specifically for additive manufacturing (AM). It is the first metal AM feedstock designed in the Middle East for use on laser powder bed fusion (LPBF) systems, offering a low-cost, high-strength aluminum alloy that demonstrates excellent printability and performance.

When compared to commercially available AlSi10Mg alloys,TII says AMALLOY registers 33% greater strength without compromising on ductility. This makes the material well suited for parts where light weight and high strength are a requirement for demanding applications.

Due to the nature of its chemical formulation and intrinsic metallurgical compounds, AMALLOY features an incredibly low hot crack susceptibility coefficient, meaning higher strengths can be achieved without hot cracking issues. Higher strengths are made possible by a robust co-eutectic microstructure combined with a high level of saturation, precipitation hardening and grain refining. In collaboration with Oxford University, Atom Probe Tomography (APT) analyses revealed the presence of nano-precipitates in the primary aluminum microstructure that further enhanced the alloy’s strength.

In addition to the excellent mechanical properties, the alloy has been tested up to temperatures of 300°C, revealing excellent thermal stability and making this grade potentially usable in high-temperature environments.

“Our focus is on developing high strength alloys with excellent printability. We intend to use these new materials in manufacturing defect-free parts to be employed in critical and high-value applications,” says Dr. Nesma Aboulkhair, Director of Additive Manufacturing at TII. “We are adopting a framework for an integrated computational and experimental approach to design and produce these new materials for use in metal AM. This framework constitutes six phases, including alloy design, experimental validation, AM for in situ-alloying with accelerated process optimization, material testing, metal powder optimization and finally, documentation.”

The framework is conducted entirely in-house from start to finish and the company says it has already proven so successful in developing AMALLOY that its has filed for a patent for the alloy with the U.S. Patent Office. TII intends to use the framework to develop new alloys from other families of metals and also expects to use the framework to develop new alloys for traditional manufacturing processes.

“The target clientiele for the new material we are developing for metal 3D printing are worldwide metal powder producers and we are exploring licensing our new patented alloy compositions to global manufacturers,” says Dr. Federico Bosio, lead researcher for additive manufacturing materials at TII. “Some of the use cases that the specific AMALLOY is suitable for include low buy-to-fly parts for aerospace/aviation (such as antennas, aircraft brackets, nanosatellites) and high-strength components such as topology optimized engine brackets.”

AMALLOY will be further enhanced using TII’s development framework, with the aim of producing a high-strength aluminum alloy specifically for high-temperature applications. Once complete, the material will open up new applications across sectors such as aerospace, space, oil and gas, and nuclear.

- For the latest information on new materials in the additive manufacturing industry, visit our Materials section.

Related Content

3D Printed Lattice for Mars Sample Return Crash Landing: The Cool Parts Show Bonus

NASA Jet Propulsion Laboratory employs laser powder bed fusion additive manufacturing plus chemical etching to create strong, lightweight lattice structures optimized to protect rock samples from Mars during their violent arrival on earth.

Read MoreNew Zeda Additive Manufacturing Factory in Ohio Will Serve Medical, Military and Aerospace Production

Site providing laser powder bed fusion as well as machining and other postprocessing will open in late 2023, and will employ over 100. Chief technology officer Greg Morris sees economic and personnel advantages of serving different markets from a single AM facility.

Read More3D Printed Brake Panel for the Rail Industry: The Cool Parts Show #52

In this episode of The Cool Parts Show, laser powder bed fusion simplifies the manufacturing of air brake panels for light rail systems made by Wabtec.

Read More25 Years Later, What’s Exciting in Electron Beam Powder Bed Fusion?

Often seen as runner-up to laser powder bed fusion, are we finally in the golden age of the electron beam?

Read MoreRead Next

4 Ways the Education and Training Challenge Is Different for Additive Manufacturing

The advance of additive manufacturing means we need more professionals educated in AM technology.

Read MoreAt General Atomics, Do Unmanned Aerial Systems Reveal the Future of Aircraft Manufacturing?

The maker of the Predator and SkyGuardian remote aircraft can implement additive manufacturing more rapidly and widely than the makers of other types of planes. The role of 3D printing in current and future UAS components hints at how far AM can go to save cost and time in aircraft production and design.

Read MoreHybrid Additive Manufacturing Machine Tools Continue to Make Gains (Includes Video)

The hybrid machine tool is an idea that continues to advance. Two important developments of recent years expand the possibilities for this platform.

Read More