Sculpteo Offers RE-cycleo 3D Printed Part Recycling Program

The program offers recycling services to Sculpteo clients not only for the clients’ obsolete parts but also for production scrap.

Sculpteo’s RE-cyleo program enables its clients to recycle obsolete parts starting from the very first unit, giving the parts a second life and contributing to the development of a more sustainable sector. The program includes parts printed with Nylon PA12 and Nylon PA11.

According to the company, the recycled material will be used in the plastics industry and give a second life to the old parts that can be recycled as many times as possible. With this initiative, Sculpteo says it becomes one of the first 3D printing services to offer its clients recycling services not only for clients’ parts but also for production scrap.

Sculpteo says the recycling program is part of its commitment to more sustainable printing. As businesses move toward a better understanding of environmental issues, it has become urgent that industries like 3D printing pave the way for more sustainable solutions, the company says.

Being concerned about the environmental impact of its activity, Sculpteo has worked to make it possible to recycle its clients’ Nylon PA11 and Nylon PA12 obsolete parts. It is said 3D printing presents certain advantages compared to other plastic manufacturing processes (local on-demand production, very low material loss and more). In this continuity, Sculpteo is expanding its line of sustainable materials such as biosourced Nylon PA11. The company continues its research to make 3D printing even more sustainable and presents an interesting initiative through this program.

“With RE-cycleo, we are inaugurating a new, more responsible way of producing, where we offer clients the possibility to upgrade their products,” says Alexandre d’Orsetti, Sculpteo CEO. “It has taken decades for mass industries to develop effective recycling programs with their gigantic volumes. At Sculpteo, we can offer it from the first part.”

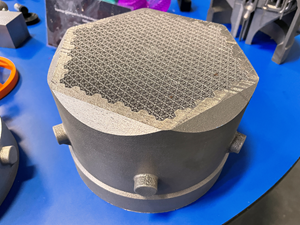

The recycling process entails clients sending obsolete parts to Sculpteo along with a destruction authorization. Once received, the first step of the process entails collecting and sorting the parts depending on the material (Nylon PA11 or Nylon PA12). The parts are then placed in octabins that can contain hundreds of kilos of parts. The sorted nylon waste is then crushed into pieces.

To maintain the industrial secrecy and confidentiality of its clients, Sculpteo guarantees that the grinding only happens inside its factory. The crushed material is then sent to Arkema, which will recycle it as part of its Virtucycle program. The grinded material is analyzed to ensure there is no contamination. Next comes the compounding stage where the material is remelted, chilled and cut into pellets that will be used in other industrial applications. These pellets form the final state of the new material which can now be used.

In the case of injection molding, the pellets will be melted and injected into a mold to create a new product such as car components, tennis rackets, shoes, helmets, a suitcase and more. This gives a second life to unused parts or end-of-life parts. The company says this whole process uses 100% renewable energy.

- Listen to this episode of AM Radio in which Dr. Tim Simpson and Stephanie Hendrixson discuss current research and future opportunities on AM Radio.

- Read how another additive manufacturing company is encouraging users to give priority to recycled filaments in the interests of sustainability and resource conservation.

- Here’s another episode of AM Radio. In this program, the AM writers discuss why additive manufacturing is often closely associated with sustainability and how can companies use AM to develop sustainable processes.

Related Content

Copper, New Metal Printing Processes, Upgrades Based on Software and More from Formnext 2023: AM Radio #46

Formnext 2023 showed that additive manufacturing may be maturing, but it is certainly not stagnant. In this episode, we dive into observations around technology enhancements, new processes and materials, robots, sustainability and more trends from the show.

Read More3D Printed Heat Exchanger Illustrates Siemens' CATCH and Release Approach

Solutions for energy efficiency, sustainability, part repair and more are developing at Siemens’ Charlotte Advanced Technology Collaboration Hub (CATCH) in North Carolina.

Read MoreHow Large-Format 3D Printing Supports Micro-Scale Hydropower

There is potential hydroelectric power that has never been unlocked because of the difficulty in capturing it. At Cadens, additive manufacturing is the key to customizing micro-scale water turbine systems to generate electricity from smaller dams and waterways.

Read More3D Printing Brings Sustainability, Accessibility to Glass Manufacturing

Australian startup Maple Glass Printing has developed a process for extruding glass into artwork, lab implements and architectural elements. Along the way, the company has also found more efficient ways of recycling this material.

Read MoreRead Next

At General Atomics, Do Unmanned Aerial Systems Reveal the Future of Aircraft Manufacturing?

The maker of the Predator and SkyGuardian remote aircraft can implement additive manufacturing more rapidly and widely than the makers of other types of planes. The role of 3D printing in current and future UAS components hints at how far AM can go to save cost and time in aircraft production and design.

Read More3D Printing Brings Sustainability, Accessibility to Glass Manufacturing

Australian startup Maple Glass Printing has developed a process for extruding glass into artwork, lab implements and architectural elements. Along the way, the company has also found more efficient ways of recycling this material.

Read MoreHybrid Additive Manufacturing Machine Tools Continue to Make Gains (Includes Video)

The hybrid machine tool is an idea that continues to advance. Two important developments of recent years expand the possibilities for this platform.

Read More

.png;maxWidth=300;quality=90)