NTU and HP Announce Corporate Innovation Lab in Asia

HP’s first university laboratory collaboration in Asia will focus on digital manufacturing technologies, from 3D printing to machine learning and more.

Nanyang Technological University, Singapore (NTU Singapore), HP Inc., and the National Research Foundation (NRF) are collaborating on a new $84 million HP-NTU Digital Manufacturing Corporate Lab.

As Singapore’s newest corporate research laboratory and HP’s largest university research collaboration worldwide, the HP-NTU Corporate Lab will drive innovation, technology, skills and economic development critical for the advancement of the Fourth Industrial Revolution. This is HP’s first university laboratory collaboration in Asia.

The lab supports Singapore’s push toward industry transformation in the areas of digital manufacturing and 3D printing technologies. “Advanced Manufacturing and Engineering” is one of four technology domains under the Research, Innovation and Enterprise (RIE) 2020 Plan, which is Singapore’s national strategy to develop a knowledge-based innovation-driven economy and society.

Located at NTU, the HP-NTU Digital Manufacturing Corporate Lab was launched by Heng Swee Keat, minister for finance and chairman of the NRF. The NRF facilitates the creation of corporate labs via public-private partnerships. The Corporate Lab is the 13th supported by NRF and the seventh such lab at NTU.

The lab’s 100 researchers and staff will focus on digital manufacturing technologies, specifically in areas of advancing 3D printing, artificial intelligence, machine learning, new materials and applications, cybersecurity and customization.

The partnership agreement was signed by NTU Vice President (Research) Prof Lam Khin Yong and HP Chief Technology Officer and Head of HP Labs Shane Wall. It was witnessed by Guest-of-Honor Minister of Finance and NRF Chairman Heng Swee Keat, NTU President Professor Subra Suresh, and HP Inc. Chief Executive Officer Dion Weisler.

"Corporate laboratories are an integral part of our strategy to anchor joint R&D partnerships between our universities and companies in areas that have direct relevance to the growth of industries in Singapore,” says Low Teck Seng, NRF professor. “The HP-NTU Digital Manufacturing Corporate Laboratory is significant to our long-term competitiveness in the advanced manufacturing sector, and ensures that we stay relevant in the Fourth Industrial Revolution that is evolving and growing rapidly world-wide. It will also strengthen our capabilities to support multinational companies for expansion from Singapore into the region.”

NTU President Prof Subra Suresh says the partnership with HP is a significant milestone for NTU, as 3D printing along with adjacent technologies such as artificial intelligence (AI), machine learning and cybersecurity are integral parts of the Fourth Industrial Revolution.

“NTU has established deep capabilities and is a recognized leader in the areas of machine learning, data science and additive manufacturing,” Suresh says. ”These cutting-edge technologies are now an integral part of NTU’s education and research ecosystem, and the NTU Smart Campus serves as a test bed for them, aligned with Singapore’s vision of transforming into a Smart Nation.”

“Together with HP Inc., a renowned innovator and leader in the tech industry, NTU seeks to address today’s fundamental challenges with solutions that will benefit both industry and society in Singapore and the world, such as developing automation that is capable of boosting manufacturing productivity,” he continues.

“The World Economic Forum estimates more than $100 trillion in value will be created by digital transformation across all industries in the next 10 years,” says Dion Weisler, CEO and president, HP Inc. “HP is helping lead the development of the underlying technologies, like 3D printing, that will enable the benefits of this transformation. Singapore is one of our key worldwide technology development and manufacturing centers in Print technology. The HP-NTU Digital Manufacturing Corporate Lab will significantly deepen our involvement here and serve as a nucleus for this ecosystem. We are proud to collaborate with NTU and we are looking forward to this becoming a blueprint for innovation, collaboration and economic progress.”

Related Content

EOS, Hyperganic Partnership to Elevate Space Components

Integration of Hyperganic Core, an AI-powered engineering software platform, with EOS’ digital additive manufacturing solutions aims to advance the space propulsion field.

Read MoreActivArmor Casts and Splints Are Shifting to Point-of-Care 3D Printing

ActivArmor offers individualized, 3D printed casts and splints for various diagnoses. The company is in the process of shifting to point-of-care printing and aims to promote positive healing outcomes and improved hygienics with customized support devices.

Read More5 Observations From Dr. Tim Simpson About the State of Additive Manufacturing So Far

The outgoing co-director of Penn State’s CIMP-3D takes stock of how far AM has come, aided in no small part through the work of the organization he helped to lead.

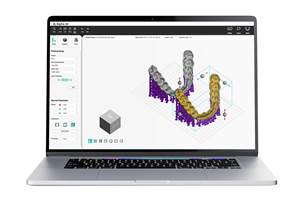

Read MoreAI-Assisted 3D Slicing Software Simplifies Dental 3D Printing Process

The software simplifies the 3D printing process so users don’t need special design training.

Read MoreRead Next

To Improve Performance of Compression Molded Composites, Add 3D Printed Preforms

9T Labs' Additive Fusion Technology enables the manufacture of composite structures with as much or as little reinforcement as is necessary, using 3D printed continuous fiber preforms to add strength just where needed.

Read MoreLooking to Secure the Supply Chain for Castings? Don't Overlook 3D Printed Sand Cores and Molds

Concerns about casting lead times and costs have many OEMs looking to 3D print parts directly in metal. But don’t overlook the advantages of 3D printed sand cores and molds applied for conventional metal casting, says Humtown leader.

Read MoreGE Additive Rebrands as Colibrium Additive

As part of the brand name transition, both the Concept Laser and Arcam EBM legacy brands will be retired.

Read More

.png;maxWidth=300;quality=90)