Nikon Invests in Hybrid Manufacturing Technologies

HMT’s technology enables users to take full advantage of the additive manufacturing process by unifying multiple complementary technologies in one setup.

Share

Read Next

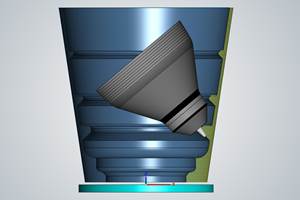

HMT has expanded the concept of “done-on-one machine” with product offerings that include metal and polymer AM, melt pool monitoring, inspection and more. Photo Credit: HMT

Nikon Corp. is investing in Hybrid Manufacturing Technologies (HMT), an additive manufacturing (AM) company which successfully created an approach that enables users to integrate additive tools onto any platform. This technology enables users to take full advantage of the manufacturing process by unifying multiple complementary technologies in one setup.

According to the company, parts manufacturers will often use AM processing and machining in tandem, depending upon their specific production goals and tolerances. HMT enabled a huge leap forward by unlocking the freedoms of additive while retaining the precision and surface finish capabilities of CNC, all in a single system.

When using the Ambit deposition heads, only a simple tool change is required to switch from cutting to adding metal, giving users greater flexibility. HMT’s tool changeable heads are not limited to laser processes but are also compatible with numerous materials and a vast array of deployment methods. HMT can upgrade existing vertical platforms to enable both additive and subtractive machining capabilities in one system, or create bespoke solutions with customized heads to meet the user's objectives.

Nikon manufactures some of the most precise equipment in the world, with its products being used in applications ranging from semiconductor manufacturing and mass production of panels for televisions and smart devices, to medical systems, automotive and satellites. Nikon established the Next Generation Project Division to accelerate the launch of new growth businesses, including advanced materials processing technologies, through synergies resulting from strategic investments and alliances with industry-leading companies worldwide.

This latest investment will enable HMT and Nikon to leverage their combined expertise to accelerate innovation and expand the hybrid manufacturing landscape. “This investment in HMT is the latest component of our Next Generation Project program to further industrialization of digital manufacturing,” says Yuichi Shibazaki, Nikon corporate vice president and general manager of the Next Generation Project Division. “As an industry leader with demonstrated collaborative capabilities, HMT and its Ambit portfolio are well-matched with Nikon technologies. We look forward to working with them as part of our commitment to creating value and advancing society through novel industries like hybrid manufacturing.”

The investment should benefit both companies. “Together we will more fully deliver on the promise of additive and digital manufacturing,” says Dr. Jason B. Jones, HMT co-founder and CEO. “We expect the results of this technology will touch the lives of virtually all people on earth in the coming decades.”

HMT believes Hybrid is all about synergy. “For the better part of 10 years in this industry, we have taken pride in the strategic nature of our collaborations and our partnership with Nikon takes this to a whole new level by adding value to advanced manufacture,” says Peter Coates, HMT co-founder and CTO.

• AMT’s Tim Shinbara includes Hybrid Manufacturing Technologies in his discussion about hybrid systems combining traditional subtractive processes with additional processes. These can include laser metal deposition for additive manufacturing and friction stir welding, enabling manufacturers to design products from the inside-out.

Related Content

Hybrid Metal 3D Printer Enables Quick-turn Prototyping

IMTS: Matsuura Machinery’s Lumex Avance hybrid metal 3D printers are said to enable lights-out production for highly accurate parts from metal powders.

Read MoreHyperMill CAM Software for Hybrid Manufacturing

IMTS 2022: The hyperMill CAM software features an additive manufacturing capability option, which is said to provide efficient hybrid processing with simultaneous additive and subtractive processing on one machine.

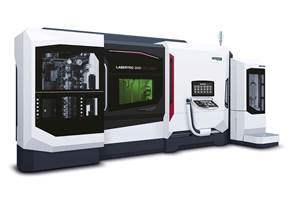

Read MoreDMG MORI’s Hybrid 3D Printer Offers 5-Axis Simultaneous Machining

DMG MORI’s Lasertec 3000 DED hybrid 3D printer offers process integration by combining laser deposition welding with 5-axis, turn-mill machining in one setup.

Read MoreHybrid Additive Manufacturing Machine Tools Continue to Make Gains (Includes Video)

The hybrid machine tool is an idea that continues to advance. Two important developments of recent years expand the possibilities for this platform.

Read MoreRead Next

At General Atomics, Do Unmanned Aerial Systems Reveal the Future of Aircraft Manufacturing?

The maker of the Predator and SkyGuardian remote aircraft can implement additive manufacturing more rapidly and widely than the makers of other types of planes. The role of 3D printing in current and future UAS components hints at how far AM can go to save cost and time in aircraft production and design.

Read More4 Ways the Education and Training Challenge Is Different for Additive Manufacturing

The advance of additive manufacturing means we need more professionals educated in AM technology.

Read MoreHybrid Additive Manufacturing Machine Tools Continue to Make Gains (Includes Video)

The hybrid machine tool is an idea that continues to advance. Two important developments of recent years expand the possibilities for this platform.

Read More

.png;maxWidth=300;quality=90)