GE Additive Helps Build Large Metal 3D Printed Aerospace Part

The research is part of an initiative to develop more fuel-efficient air transport technologies as well as a strong, globally competitive aeronautical industry supply chain in Europe.

Share

Read Next

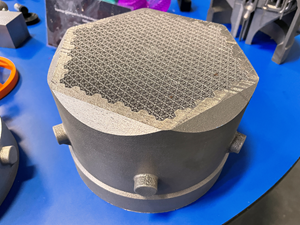

The one-meter-in-diameter part was additively manufactured in nickel alloy 718 on a GE Additive system using the direct metal laser melting (DMLM) process. Photo Credit: GE Additive

GE Additive is working to develop larger, lighter additive parts. It’s part of the GE Aerospace Advanced Technology Munich-led European consortium which created one of the largest ever metal 3D-printed aerospace parts — a part that also demonstrates significant cost, weight and time savings.

The EU’s European Green Deal sets out to reduce transport emissions by 90% by 2050 (compared to 1990 levels) with the aviation sector playing its part. Priorities going forward include financial and regulatory measures to drive low-emissions aviation and the urgent development of clean sheet frames, new aircraft engines and propulsion systems, and sustainable aviation fuel.

One significant research initiative underway to develop these types of more fuel-efficient air transport technologies for the earliest possible deployment is the European Commission and European aerospace industry-funded Clean Sky 2 Programme, now entering its final phase. Its successor, Clean Aviation, was launched in December 2021.

The Clean Sky 2 program is made up of key industry players and subject matter experts along with academic research bodies across Europe. The program is integrating, demonstrating and validating technologies capable of reducing CO2 emissions as well as nitrous oxide (NOx) and noise emissions by up to 30% compared to 2014’s state-of-the-art aircraft. Another goal is to develop a strong and globally competitive aeronautical industry and supply chain in Europe.

Based in Munich, Germany, the GE Aerospace Advanced Technology (GE AAT) Munich team leads three core partnerships in the Clean Sky 2 program to identify engine hardware, benefits, design, manufacturing process and, connected to the program’s goals, collaborate closely with GE Aerospace’s sites in Italy, Czech Republic, Poland and Turkey, as well as external partners.

One of the GE AAT Munich-led partnerships is the Turbine Technology Project (TURN), which was set up to accelerate technology maturation for future aero engines. And, in response to a Clean Sky 2 call for proposals in 2018, a consortium of Hamburg University of Technology (TUHH), TU Dresden (TUD) and technology company Autodesk was selected to support GE AAT Munich for the design and manufacturing of a large-scale metal additive manufacturing component – the Advanced Additive Integrated Turbine Centre Frame (TCF) casing – the MONACO project. This also included the design and production of coupons and critical parts, validation and qualification, and the final delivery of the full-sized metal 3D printed casing.

After almost six years in R&D and engineering, the large-format TCF casing design using GE

Additive’s Direct Metal Laser Melting (DMLM) technology in nickel alloy 718 was recently unveiled by the consortium. The TCF casing is one of largest additively manufactured parts produced for the aerospace industry.

The additively manufactured TCF casing is designed for narrow-body engines in which the part is approximately one meter or more in diameter. Having this single-piece design solution to produce this kind of large format engine hardware with reduced cost, weight and manufacturing lead time gives a competitive business advantage.

“We wanted to reduce the weight of the part by 25%, but also improve the pressure losses of the secondary air flow as well as a strong reduction in part count to improve maintenance,” says Dr. Günter Wilfert, GE AAT Munich’s technology and operations manager.

The shift from conventional casting to AM reduced cost and weight by 30%. The consolidation combined more than 150 parts into one and lead time was reduced from more than nine months down to only two-and-a-half months.

The team can be proud of the results. “Those targets were achieved and surpassed. We were able to reduce the weight by ~30% in the end. The team also reduced the manufacturing lead time from nine months to two and a half months, by approximately 75%. Over 150 separate parts that make up a conventional turbine center frame casing have been consolidated into one single piece design,” Wilfert adds.

Outside of the environmental, performance, weight, cost benefits and reduction of waste material of this new part, perhaps the biggest impact will be supply chain disruption in all industries facing challenges with their casting in conventional manufacturing.

Due to stringent requirements on airworthy hardware in the highly regulated aerospace industry, the number of approved vendors for casting and forging parts is very limited. This creates long lead times and high costs. These challenges, and the fact that a turbine center frame isn’t a rotating part, made it an ideal candidate for additive manufacturing.

“Additive manufacturing offers enormous potential to lower weight, improve component functionalities, and substantially reduce part count in complex assemblies, directly increasing aircraft energy efficiency, and reducing assembly costs and time,” says Christina-Maria Margariti, project officer for hydrogen-powered aircraft for Clean Aviation.

“The Clean Aviation program, in line with the EU Green Deal objective of carbon neutrality by 2050, supports the launch of disruptive new products by 2035, with the aim to replace 75% of the operating fleet by 2050. Faster time to market and increased production rates will therefore be crucial to reaching these ambitious environmental targets,” Margariti adds.

- Read about the GE Additive collaboration with WSU-NAIR to accelerate the military’s metal additive technology implementation.

- Learn about the work of the U.S. Air Force and GE Additive in the Pacer Edge Program — a metal additive manufacturing (AM) pathfinder to showcase the application of AM in aerospace.

Related Content

Evaluating the Printability and Mechanical Properties of LFAM Regrind

A study conducted by SABIC and Local Motors identified potential for the reuse of scrap reinforced polymer from large-format additive manufacturing. As this method increases in popularity, sustainable practices for recycling excess materials is a burgeoning concern.

Read More3D Printed Heat Exchanger Illustrates Siemens' CATCH and Release Approach

Solutions for energy efficiency, sustainability, part repair and more are developing at Siemens’ Charlotte Advanced Technology Collaboration Hub (CATCH) in North Carolina.

Read MoreWhy This Photopolymer Developer Wants Prototyping to Go “Massless”

High-performance materials supplier polySpectra is embracing augmented reality (AR) with a new tool called Massless intended to reduce unnecessary 3D printing.

Read MoreCan the U.S. Become Self-Sufficient in Aerospace Alloy Metal Powders?

6K’s technology can upcycle titanium and nickel-alloy parts into additive manufacturing powder. Here is how the circular economy helps national security.

Read MoreRead Next

4 Ways the Education and Training Challenge Is Different for Additive Manufacturing

The advance of additive manufacturing means we need more professionals educated in AM technology.

Read MoreHybrid Additive Manufacturing Machine Tools Continue to Make Gains (Includes Video)

The hybrid machine tool is an idea that continues to advance. Two important developments of recent years expand the possibilities for this platform.

Read MoreAt General Atomics, Do Unmanned Aerial Systems Reveal the Future of Aircraft Manufacturing?

The maker of the Predator and SkyGuardian remote aircraft can implement additive manufacturing more rapidly and widely than the makers of other types of planes. The role of 3D printing in current and future UAS components hints at how far AM can go to save cost and time in aircraft production and design.

Read More

.png;maxWidth=300;quality=90)