Fraunhofer ILT, 6K Additive Partner on AM Life Cycle Assessment

The study conducted at the labs of Fraunhofer ILT analyzes an additively manufactured industrial component that includes the environmental impact from powder, printing and postprocessing.

Share

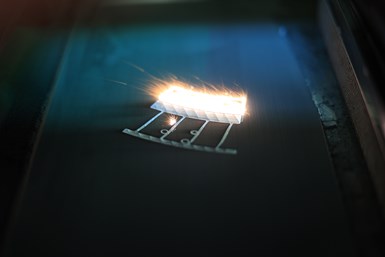

The assessment found that for Ni718 powder, 6K’s UniMelt process delivered at a minimum a 91% energy reduction and 92% carbon emission reduction from traditional processes. Photo Credit: 6K Additive

6K Additive, a division of 6K, and the Fraunhofer Institute for Laser Technology (ILT), are collaborating to create a complete life cycle assessment (LCA) for additive manufacturing (AM). The study will use sustainably manufactured Ni718 powder, produced by 6K Additive, for an industrial component manufactured on a laser powder bed fusion (LPBF) machine to better understand the carbon footprint from material through AM process and postprocessing.

“There are conflicting views on additive manufacturing regarding its environmental impact compared to traditional manufacturing,” says Dr. Jasmin Saewe, Fraunhofer ILT’s head of department for laser powder bed fusion. “The goal for this study is to analyze factual data to help us understand the real environmental impact for printing a metal AM part using LPBF. We also thought it was extremely important to evaluate the entire process, including powder manufacturing, which is why we partnered with 6K Additive, who has a proven method of sustainable powder manufacturing.”

It is said 6K’s UniMelt platform offers multifaceted sustainability benefits. 6K Additive previously released two life cycle assessment projects for both titanium and nickel powders. This study was conducted by Foresight Management, an independent company that quantified the environmental impact associated with the production of printable metal powders and specifically compared atomization technology methods to 6K Additive’s. It was found that for Ni718 powder, 6K’s UniMelt process, at minimum, delivered a 91% energy reduction and 92% carbon emission reduction from traditional processes. The independent study can be downloaded.

“We are excited to partner with Jasmin and her team at Fraunhofer ILT for this research,” says Frank Roberts, 6K Additive president. “Our previous study clearly highlighted the environmental advantages our UniMelt technology has over atomization, but this collaboration takes it to the next step shedding light on the entire AM process. The market has embraced sustainability and the results of this study will provide the tools to allow customers to identify real solutions and help organizations drive toward carbon neutrality.”

6K Additive says it is the world’s first producer of AM powder made from sustainable sources and offers a full suite of premium powders, including nickel, titanium, copper and refractory metals such as tungsten and rhenium. The UniMelt system is a microwave production-scale plasma system, with a uniform and precise plasma zone with zero contamination and high throughput production capabilities.

- Learn about 6K Additive’s Environmental Sustainability Research Award from the Additive Manufacturing Green Trade Association (AMGTA) for its work on the UniMelt powder manufacturing process.

- Read about the 6K Additive partnership with Incodema3D in which 6K says its nickel alloy 625 powder surpassed every quality measure for powder supply and recycling in tests performed by Incodema3D.

- Take a look at this article which details the results of an independent analysis that shows 6K Additive’s UniMelt process uses 91% less energy with a 92% reduction in carbon emissions over traditional methods for nickel production.

Related Content

DMG MORI: Build Plate “Pucks” Cut Postprocessing Time by 80%

For spinal implants and other small 3D printed parts made through laser powder bed fusion, separate clampable units resting within the build plate provide for easy transfer to a CNC lathe.

Read MoreNew Zeda Additive Manufacturing Factory in Ohio Will Serve Medical, Military and Aerospace Production

Site providing laser powder bed fusion as well as machining and other postprocessing will open in late 2023, and will employ over 100. Chief technology officer Greg Morris sees economic and personnel advantages of serving different markets from a single AM facility.

Read More3D Printed Cutting Tool for Large Transmission Part: The Cool Parts Show Bonus

A boring tool that was once 30 kg challenged the performance of the machining center using it. The replacement tool is 11.5 kg, and more efficient as well, thanks to generative design.

Read MoreCopper, New Metal Printing Processes, Upgrades Based on Software and More from Formnext 2023: AM Radio #46

Formnext 2023 showed that additive manufacturing may be maturing, but it is certainly not stagnant. In this episode, we dive into observations around technology enhancements, new processes and materials, robots, sustainability and more trends from the show.

Read MoreRead Next

At General Atomics, Do Unmanned Aerial Systems Reveal the Future of Aircraft Manufacturing?

The maker of the Predator and SkyGuardian remote aircraft can implement additive manufacturing more rapidly and widely than the makers of other types of planes. The role of 3D printing in current and future UAS components hints at how far AM can go to save cost and time in aircraft production and design.

Read More3D Printing Brings Sustainability, Accessibility to Glass Manufacturing

Australian startup Maple Glass Printing has developed a process for extruding glass into artwork, lab implements and architectural elements. Along the way, the company has also found more efficient ways of recycling this material.

Read More4 Ways the Education and Training Challenge Is Different for Additive Manufacturing

The advance of additive manufacturing means we need more professionals educated in AM technology.

Read More

.png;maxWidth=300;quality=90)