3D-Printed "Smart" Shaft Introduces AI Possibilities

VTT Technical Research Centre introduces a process for 3D printing a metal shaft with embedded sensors.

Share

Read Next

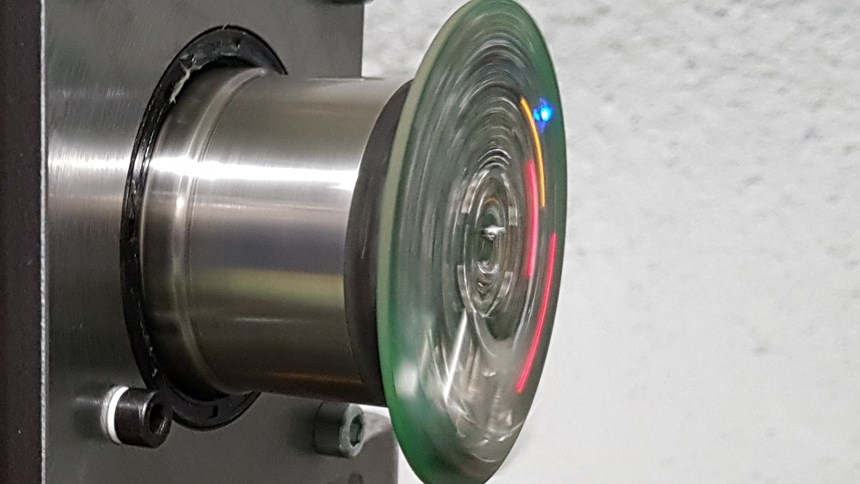

VTT Technical Research Centre of Finland has 3D-printed a “smart” shaft, using a process which the company says is a step toward artificial intelligence (AI) development. The overall process management chain includes 3D printing, sensor technology, wireless data transfer and condition monitoring in the same package. The company’s methods are designed to enable the creation of new business models and to provide a competitive edge in developing AI.

According to the company, the research focus was the creation of a way for sensors to form a functional part of a 3D-printed metal structure. The resulting methods enable a range of sensors or smart identifications to be added to 3D-printed metal parts during manufacture. The sensors can track the performance and condition of machines or devices, or verify the authenticity of the parts.

During the manufacturing phase, an accelerometer and wiring are embedded into a 3D-printed metal shaft for a friction bearing. Electronics allowing wireless communication are installed onto the bearing allowing wireless data to be directly and rapidly transferred from the component to the cloud. This could lead to developments in artificial intelligence, the company says.

The method provides the designer with a large degree of freedom compared to traditional manufacturing methods, the company says, as it enables sensors to provide up-to-date information such as maintenance status without breaks in production.

Possible applications include industrial manufacturing, energy, mining and transport. Embedded sensors are designed for demanding conditions, the company says, because the sensors and wiring are protected inside the component, and normal functioning is unimpeded by extraneous wiring on the surfaces of structures.

Related Content

-

Formlabs Part Removal Mechanism Enables Lights-Out Production

A build platform overcoming the need for manual part removal enables automated part handling, and therefore continuous production from one build cycle to the next.

-

Robot Deposition Makes Giant Industrial Mixer Blade: The Cool Parts Show Bonus

Wire arc additive manufacturing produces a large component formerly made through casting, and allows for redesign of its internal cooling geometry.

-

500-Pound Replacement Part 3D Printed by Robot: The Cool Parts Show #50

Our biggest metal cool part so far: Wire arc additive manufacturing delivers a replacement (and upgrade) for a critical bearing housing on a large piece of industrial machinery.