How Prototyping Addresses Unknowns and Reduces Risks

One benefit of metal AM is the capability to create functional prototypes in less time, enabling you to rapidly iterate on design alternatives during development.

Share

Regardless of whether you are trying to save cost, minimize mass or maximize performance with additive manufacturing (AM), you will invariably face new unknowns and uncertainties, which translate into new risks. AM is still an infant compared to machining, forging and casting, the elder statesman of manufacturing.

Recall that 3D Systems introduced the first AM technology to the market just over three decades ago, a process now referred to as vat photopolymerization, and metal AM systems have only been commercially available since the mid-2000’s; so, it should not be a surprise that there are still so many unknowns and uncertainties with AM. These unknowns and uncertainties create new risks for AM.

So how are people handling AM risks in the industry? Well, the U.S. (along with many other countries) have collectively poured many millions, if not a few billion, of dollars into research and development to understand the complex physics, heat transfer and materials science in AM processes, particularly laser powder bed fusion. This is essential to understanding the process-structure-property relationships that drive the performance, durability and useful life of the resulting parts made with AM. If that is understood, then we can control the AM process to achieve the material microstructure that we need to get the mechanical properties that we want to meet the requirements that have been set for the part. Sounds easy, but it is not.

So if you find yourself uncertain about how an AM part will build or perform and you don’t have millions of dollars (or time) to invest to figure it out, what do you do? Well, if you can’t find a solution documented in a report or a paper, and if other companies are not willing to share that information with you (because they have invested millions to mitigate the risk, giving them a competitive advantage), then you do what we have been doing since 3D printing hit the market: you prototype, but this time, you do it more intelligently and you do it fast.

One of the benefits of metal AM is the capability to create functional prototypes in less time, enabling you to rapidly iterate on design alternatives during development. Meanwhile, because AM is a digital process that does not require any tooling (beyond a build plate or platform), it makes no difference whether you are printing the entire part or just a sample or section of the part to test. In fact, you can even print variations of a single feature on a part and run tests to see what prints best and thus reduce the risk associated with that unknown.

Combining these three aspects together, we do what I refer to as Rapid Intelligent Prototyping, or R.I.P. — a cost efficient and effective approach to address unknowns and reduce risks with AM. The approach is by no means new or unique, and nearly every company that I have worked with does some form of this, albeit under different names. In fact, it seems that anyone using AM, particularly metal AM, eventually comes to the same conclusion as you try and maximize learning at minimal cost.

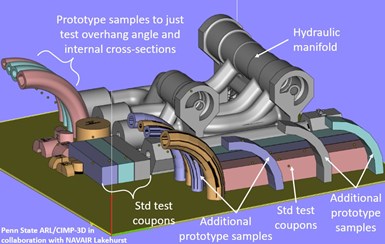

The extra space on a build plate can be used to print small samples and variations to address unknowns or associated risks with a metal AM part made using laser powder bed fusion. Photo Cred: Penn State CIMP-3D

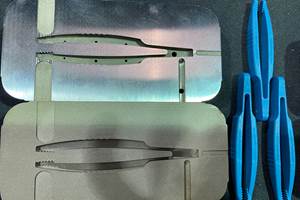

We naturally started doing this on some of our early AM projects a decade ago. We were simply trying to understand how the overhang angle and internal cross-section of a hollow metal tube influenced the internal and external surface roughness, which might impact the flow in the AM hydraulic manifold we were helping to develop. As a result, we simply printed several small sample prototypes with slight variations on that specific geometry (see Figure 1) so that we could take measurements on the as-built and post-processed surface roughness.

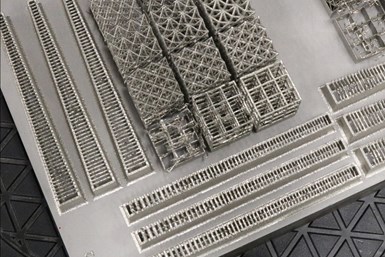

Our thinking has gotten more creative and sophisticated over the years, but I am still learning. In fact, we were recently building some small lattices, printing small 3 × 3 cubes (versus the full-size structure) in various materials and configurations to examine the printability of unsupported horizontal struts of different lengths and thicknesses. Eventually we realized that we did not need to print the whole 3 × 3 cube, let alone a unit cell; we simply needed to print horizontal struts of varying length and cross-section thickness to answer the question we had. This turned into little xylophone-like structures that could be visually inspected for failure and easily measured while on the build plate (see Figure 2). I still remember smacking myself in the head two or three builds into our testing when I realized that we were “over-printing” for our experiments — we weren’t quite as rapid or as intelligent as we could have been!

Anyone doing process parameter development takes a similar approach. Don’t try and print the whole part while varying process parameters and toolpaths; rather, start with simple lines and layers before working up to cubes and more complex geometries. There is no sense building a small cube, for instance, if you can’t get a good layer, and you will never get a good layer if you cannot lay down a good bead/track in the first place.

Over the years, I have seen countless examples of small prototypes, sample parts or feature variation studies printed in the “extra space” on a build plate like we did early on with our hydraulic manifold. These are different from the witness coupons, tensile bars and other test coupons that are necessary for quality assurance and control. We still need those too, but in the early stages of new product development, the uncertainty and unknowns are often closely linked to printable geometry since detailed design guidelines are not ubiquitous yet.

Most people probably do some form or another of this already. For others, it is yet another reminder to think differently when it comes to AM — not only about what can be designed and manufactured, but also about how to design and develop a part from the start. Then when you uncover some unknown or have a question on what will (or will not) print, be smart and say R.I.P. to the AM risk.

Related Content

Faster Iteration, Flexible Production: How This Inflation System OEM Wins With 3D Printing

Haltec Corp., a manufacturer of tire valves and inflation systems, finds utility in 3D printing for rapid prototyping and production of components for its modular and customizable products.

Read More3D Printing Enables Mold Shop to Rapidly Prototype Medical Parts (Video)

A case study involving Mantle’s 3D printing technology allowed moldmaker Westminster Tool to go from design to injection molded prototype medical parts in three weeks.

Read MorePowderCleanse Concept Delivers In Situ Powder Analysis for Metal 3D Printing

A collaborative project developed a prototype solution for measuring particle size distribution on the production floor, as part of the sieving step typical to additive manufacturing processes using metal powders.

Read MoreIndyCar's 3D Printed Top Frame Increases Driver Safety

The IndyCar titanium top frame is a safety device standard to all the series' cars. The 3D printed titanium component holds the aeroscreen and protects drivers on the track.

Read MoreRead Next

Hybrid Additive Manufacturing Machine Tools Continue to Make Gains (Includes Video)

The hybrid machine tool is an idea that continues to advance. Two important developments of recent years expand the possibilities for this platform.

Read More3D Printing Brings Sustainability, Accessibility to Glass Manufacturing

Australian startup Maple Glass Printing has developed a process for extruding glass into artwork, lab implements and architectural elements. Along the way, the company has also found more efficient ways of recycling this material.

Read More4 Ways the Education and Training Challenge Is Different for Additive Manufacturing

The advance of additive manufacturing means we need more professionals educated in AM technology.

Read More

.png;maxWidth=300;quality=90)