Ford in Production with On-Demand AM Polymer Parts

Ford and Carbon presented the first digitally manufactured polymer parts in production for the Ford Motor Company, created with Carbon’s digital light synthesis technology.

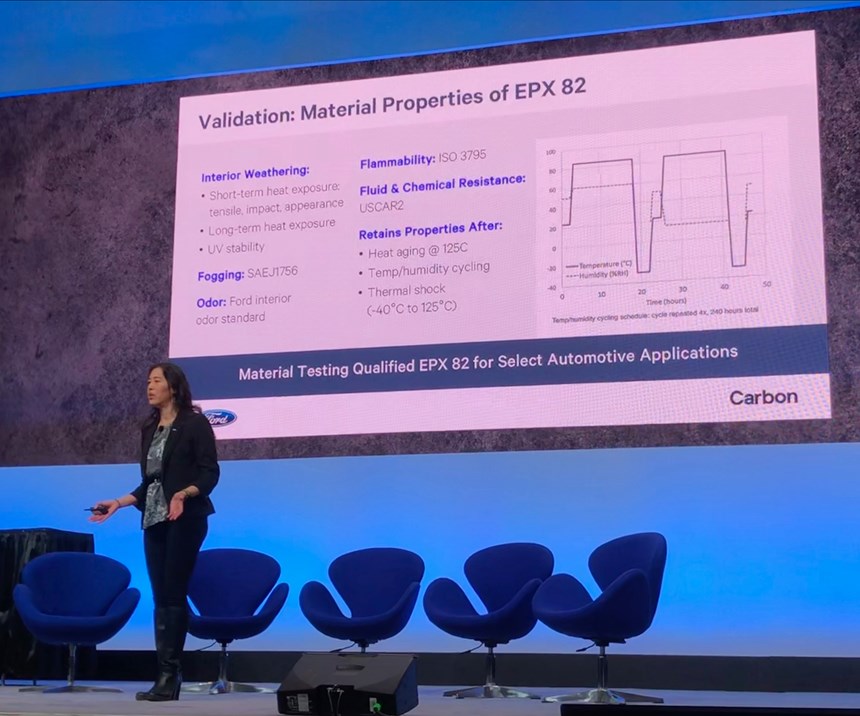

In case you missed it, the very first presentation of the inaugural Additive Manufacturing Workshop for Automotive (AMWA) broke actual news. The event, which took place at this year’s North American International Auto Show (NAIAS) in Detroit on January 16, kicked off with a presentation by Ellen Lee, Ph.D., Additive Manufacturing Technical Leader, Ford Motor Company, and Paul Dilaura, Vice President, Enterprise Partnerships, Carbon. The two showcased the first digitally manufactured polymer parts in production for the Ford Motor Company, including a Ford Focus HVAC lever arm (a service component for older models), heavy-duty truck auxiliary plugs (a niche market part) and electric parking brake brackets.

The parts, created with Carbon’s digital light synthesis technology using a Ford-qualified epoxy material, exceeded rigorous performance testing and critical requirements such as interior weathering, short- and long-term heat exposures, UV stability, fluid and chemical resistance, flammability and fogging.

Lee and DiLaura’s presentation includes in-depth explanations of the production process for the additively produced parts, including ancillary benefits regarding the elimination of inventory and warehouse requirements, drastically reduced lead times and minimum order quantities. The two presenters give detailed explanations about additive processes for parts being printed for vehicles ranging from the Mustang GT500 to the Ford F-150 Raptor. To watch the entire presentation—for free—simply register here.

Related Content

-

Large-Format “Cold” 3D Printing With Polypropylene and Polyethylene

Israeli startup Largix has developed a production solution that can 3D print PP and PE without melting them. Its first test? Custom tanks for chemical storage.

-

How to Build 10,000+ Shot Molds in Hours

Rapid tooling isn’t so rapid when it takes days to 3D print a metal mold, and then you still must machine it to reach the necessary tolerances. With Nexa3D’s polymer process you can print a mold in hours that is prototype or production ready and can last for more than 10,000 shots.

-

Multimaterial 3D Printing Enables Solid State Batteries

By combining different 3D printing processes and materials in a single layer, Sakuu’s Kavian platform can produce batteries for electric vehicles and other applications with twice the energy density and greater safety than traditional lithium-ion solutions.