Jabil’s PLA 3110P Is Bio-Based Alternative to Petrochemical-Based Powders

The engineered material can advance sustainability initiatives while providing a low-carbon alternative to nylon-based materials.

Share

Read Next

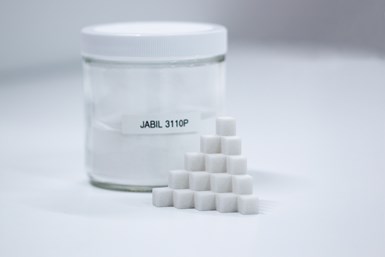

Jabil PLA 3110P, based on NatureWorks’ Ingeo PLA-based powder, is said to offer an 89% smaller carbon footprint compared to PA 12 when used in powder-bed fusion technologies. Photo Credit: Jabil

Jabil’s PLA 3110P is a novel powder based on a renewably sourced biomaterial that offers a bio-based alternative to petrochemical-based powders, such as Nylon-12 (PA 12). Developed in collaboration with NatureWorks — a manufacturer of polylactic acid (PLA) biopolymers —Jabil says its PLA 3110P material is made with NatureWorks Ingeo PLA and leverages Jabil’s “beaker-to-box” material innovations to deliver the first-ever PLA-based powder optimized for powder bed fusion technologies.

“Breakthroughs in material innovations are being driven by the need for better performing polymers,” says Luke Rodgers, senior director of R&D for additive manufacturing at Jabil. “We applied advanced morphology control to produce this sustainable and bio-based powder based on NatureWorks’ Ingeo biopolymer. Together, we are enabling an entirely new class of PLA material for the growing ecosystem of open additive manufacturing platforms.”

Jabil and NatureWorks collaborated to create, test and validate the PLA 3110P powder by combining NatureWorks’ expertise in PLA technologies with Jabil’s experience in developing polymer formulations, novel compounds and material system integration. As a result, the engineered material can advance sustainability initiatives while providing a low-carbon alternative to nylon-based materials.

“We are excited to join Jabil in launching the first Ingeo-based powder for open selective laser sintering (SLS) printing platforms,” said Salvador Ortega, global industry manager for NatureWorks. “Our Ingeo material is a lower-cost alternative with a carbon footprint that is 89% smaller than PA 12, which makes it well suited for a wide variety of additive manufacturing applications.”

NatureWorks says its Ingeo biopolymer helps convert atmospheric carbon dioxide into new performance powder, resulting in a smaller carbon footprint than incumbent materials. According to the companies, the material offers 89% smaller carbon footprint compared to PA 12 when used in powder-bed fusion technologies, according to Jabil.

The companies also say the materials is the first to market PLA-based powder to fulfill the need for general prototyping, thermoforming and compression fabrication, such as dental molds. The PLA 3110P material now gives customers more material choices for making prototypes as well as manufacturing brackets, jigs, fixtures and tooling. Moreover, the new PLA powder is an eco-friendly option for producing the precision geometries needed for thermoforming and compression molds, including custom dental impressions.

According to research firm SmarTech Analysis, polymer additive manufacturing technologies are forecasted to move into a multitude of industries over the next decade, with print production growing to nearly $26 billion annually by 2030.

Jabil says it continually applies polymer science advancements to elevate commodity resins with value-added attributes. Over the past two years, Jabil has introduced several materials, including PA 0600, which provides the high strength and stiffness associated with Delrin or alternative POM materials without the risk of exposure to formaldehyde emissions when the material is overheated.

In 2022, Jabil released PK 5000 which features high-impact strength, high-abrasion resistance and improved elongation over other nylon materials. The polyketone resin used to make PK 5000 is an eco-friendly, low-carbon material made from carbon monoxide, which can further reduce carbon footprints.

- Learn about Jabil’s PK 5000 material that was developed for improved strength and chemical resistance. The engineered material is said to offer high barrier properties and low-moisture absorption, which may be critical for ensuring the quality and resilience of certain parts and products exposed to fuel and water.

- Read about the Titan and Jabil partnership that customizes formulations for pellet extrusion 3D Printing. The partnership qualifies and integrates customized materials for use on Titan’s pellet-based Atlas 3D printers to produce stronger, lighter and more flexible parts.

Related Content

The AM Ecosystem, User Journeys and More from Formnext Forum Austin: AM Radio #43

Sessions and conversations at the first U.S. Formnext event highlighted the complete additive manufacturing ecosystem, sustainability, the importance of customer education, AM user journeys and much more.

Read MoreNext-Gen Horse Trailers to Be Built With Robotic 3D Printing

Double D Trailers is currently developing a prototype horse trailer that will be made with large-format additive manufacturing. The technology brings potential benefits for labor, weight and design features to this subset of recreational vehicles.

Read MoreHow Large-Format 3D Printing Supports Micro-Scale Hydropower

There is potential hydroelectric power that has never been unlocked because of the difficulty in capturing it. At Cadens, additive manufacturing is the key to customizing micro-scale water turbine systems to generate electricity from smaller dams and waterways.

Read More3D Printing Brings Sustainability, Accessibility to Glass Manufacturing

Australian startup Maple Glass Printing has developed a process for extruding glass into artwork, lab implements and architectural elements. Along the way, the company has also found more efficient ways of recycling this material.

Read MoreRead Next

3D Printing Brings Sustainability, Accessibility to Glass Manufacturing

Australian startup Maple Glass Printing has developed a process for extruding glass into artwork, lab implements and architectural elements. Along the way, the company has also found more efficient ways of recycling this material.

Read MoreAt General Atomics, Do Unmanned Aerial Systems Reveal the Future of Aircraft Manufacturing?

The maker of the Predator and SkyGuardian remote aircraft can implement additive manufacturing more rapidly and widely than the makers of other types of planes. The role of 3D printing in current and future UAS components hints at how far AM can go to save cost and time in aircraft production and design.

Read More4 Ways the Education and Training Challenge Is Different for Additive Manufacturing

The advance of additive manufacturing means we need more professionals educated in AM technology.

Read More

.png;maxWidth=300;quality=90)