EOS’ AlSi10Mg and Virtucycle Take-Back Program Support Sustainable Additive Manufacturing

Both the reformulated AlSi10Mg and new polymer take-back program are designed to help reduce material waste in manufacturing.

EOS’ aluminum AlSi10Mg material and its Virtucycle used polymer take-back program both help minimize the climate impact of additive manufacturing (AM). The AlSi10Mg is the latest addition to the company’s Responsible Products manufacturing portfolio, while the polymer take-back program helps to reduce material waste.

The reformulated AlSi10Mg is an example of its efforts for sustainability in 3D printing through more eco-friendly product development. Aluminium AlSi10Mg — which is one of the most popular products in its portfolio — now incorporates a minimum of 30% recycled feedstock, thereby achieving a 25% CO2e reduction compared to the prior formulation.

The company says the new formulation maintains the same properties, characteristics and performance in additively manufactured parts, helping ensure existing EOS Aluminium AlSi10Mg customers do not need to requalify applications. Specifications for AlSi10Mg remain unchanged. The chemical composition standard is AlSi10Mg with an ultimate tensile strength of 460 MPa and a yield strength of 245 MPa. The elongation at break is 5%. It also boasts good thermal and electrical conductivity with the possibility of heat treatment.

“Our commitment to offering responsible products that support AM production is growing to include our metal materials,” says Sophia Heyl, product specialist, metal materials at EOS. “We are striving to create carbon footprint transparency for our premium metal materials. These externally verified numbers are also providing transparency to our customers by including these materials in our Carbon Calculator, furthering sustainability initiatives for both our customers and for EOS.”

Virtucycle Used Polymer Material Take-Back Program Now Available

EOS has also partnered with Agiplast, an Arkema company, to offer its new Virtucycle program. The Virtucycle program takes used polymer material and components, using 100% sustainably sourced energy, to transform AM powder into recycled, high-performance injection molding granules. To verify the positive impact of this circular economy program, EOS performed a life cycle analysis, externally verified by TÜV Süd, confirming 1 kg of polymer material turned into 0.945 kg* granules, saves approximately 7 kg CO2e in comparison to raw material. (* The difference stems from losses in the process.)

EOS says it is continuously identifying and reducing CO2e emissions throughout its supply chain, expanding the responsible mindset to encompass all areas of its business. Additional EOS Responsible Products currently available include:

- PA 1101 ClimateNeutral with 100% proven quality and zero CO2e, ClimateNeutral materials are biobased products where all remaining GHG emissions are offset with Gold Standard carbon credits.

- PA 2200 CarbonReduced materials and products where GHG emissions are reduced significantly by suitable measures such as green energy in the production process.

- Carbon Calculator considers AM project carbon emissions with key cost metrics to provide an estimation of the organization’s AM CO2e and expenses.

“I am delighted that we are continuing our way towards Responsible Manufacturing and expanding our portfolio of Responsible Products stepwise,” says Björn Hannappel, head of sustainability, EOS. “By minimizing waste, reducing the environmental footprint and prioritizing eco-friendly materials, organizations can both protect our planet and create a more efficient and resilient business model.”

Related Content

GE Additive Helps Build Large Metal 3D Printed Aerospace Part

The research is part of an initiative to develop more fuel-efficient air transport technologies as well as a strong, globally competitive aeronautical industry supply chain in Europe.

Read More3D Printing Brings Sustainability, Accessibility to Glass Manufacturing

Australian startup Maple Glass Printing has developed a process for extruding glass into artwork, lab implements and architectural elements. Along the way, the company has also found more efficient ways of recycling this material.

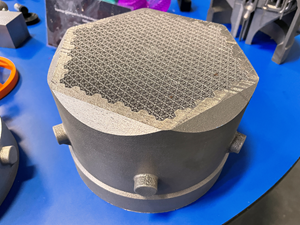

Read More3D Printed Heat Exchanger Illustrates Siemens' CATCH and Release Approach

Solutions for energy efficiency, sustainability, part repair and more are developing at Siemens’ Charlotte Advanced Technology Collaboration Hub (CATCH) in North Carolina.

Read MoreEvaluating the Printability and Mechanical Properties of LFAM Regrind

A study conducted by SABIC and Local Motors identified potential for the reuse of scrap reinforced polymer from large-format additive manufacturing. As this method increases in popularity, sustainable practices for recycling excess materials is a burgeoning concern.

Read MoreRead Next

Looking to Secure the Supply Chain for Castings? Don't Overlook 3D Printed Sand Cores and Molds

Concerns about casting lead times and costs have many OEMs looking to 3D print parts directly in metal. But don’t overlook the advantages of 3D printed sand cores and molds applied for conventional metal casting, says Humtown leader.

Read MoreTo Improve Performance of Compression Molded Composites, Add 3D Printed Preforms

9T Labs' Additive Fusion Technology enables the manufacture of composite structures with as much or as little reinforcement as is necessary, using 3D printed continuous fiber preforms to add strength just where needed.

Read MoreGE Additive Rebrands as Colibrium Additive

As part of the brand name transition, both the Concept Laser and Arcam EBM legacy brands will be retired.

Read More

.jpg;maxWidth=300;quality=90)