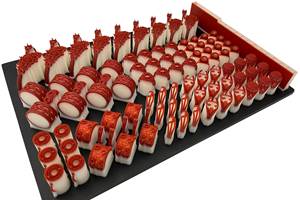

Model No. produces custom, sustainable furniture from a combination of bio-based and recycled 3D printed polymers and responsibly sourced hardwood. This Adirondack and Solis Side Table were designed specifically for the needs of a client looking for outdoor furniture. Source: Model No.

“At a certain point, we had to put a stake in the ground and decide,” says Phillip Raub, CEO at Model No. “Are we a 3D printer manufacturing company? Or are we a furniture company?”

At its founding in 2018, Model No. had to be both. The company, based in Oakland, California, was started to deliver customizable furniture produced on demand, made through a combination of polymer large format additive manufacturing (LFAM) and CNC-cut sustainable wood. Furniture was initially offered directly to consumers through an online storefront that included a parametric design editor allowing buyers to directly modify the size and configuration of their purchases. The pieces designed with this in-house software were then produced with 3D printers Model No. also developed and maintained itself.

“The tools we needed weren’t available at the time, or were too expensive for a startup on a shoestring budget,” Raub says. “We had a technical team, so they built our first 3D printers.”

Those early machines allowed Model No. to prove out the market for sustainably made, customizable furniture produced from 3D printed PLA and machined hardwood. But they also hindered its progress as furniture production scaled to higher quantities.

Frequent 3D printer maintenance was an unavoidable part of Model No.’s operations when the company was working with LFAM printers developed in-house. Source: Model No.

“There were limits on the kind of parts those printers could do,” Raub recalls. “Consistency was a problem. If we made a successful prototype on one printer, we had to produce on that same printer. There was no ability to transfer between the machines and maintain consistency.”

Upkeep was also a problem; the various components of the 3D printers were chosen more for affordability and availability than durability, which led to frequent repairs and downtime. Replacement parts were not always easily or quickly obtainable. Any delay in the supply chain of 3D printer parts could lead to significant bottlenecks in the production of furniture.

Outsource to Maintain Focus

Adopting 3D Systems’ Titan EXT Pellet printers has enabled Model No. to spend less time on machine upkeep and more time focused on designing and creating furniture, says Phillip Raub, CEO. Source: Model No.

After a couple of years, Model No. had reached the moment of choice between its product and the equipment it had been forced to develop in order to deliver that product.

“We decided we’re not in the business of building 3D printers,” Raub says. “So we said, who is?”

The answer that Model No. found was Titan Robotics, a large-format 3D printer supplier located in Colorado. The company, which was acquired by 3D Systems in 2022, delivered industrial-focused printers through a vertically integrated business model. The 3D printers, now known as 3D Systems’ EXT Titan Pellet systems, use machine tool components including ballscrews, servomotors and industrial CNC controllers, and many key components are built in-house.

Over the last few years Model No. has phased out its homegrown printers in favor of the 3D Systems platform. It now owns three EXT 1070 Titan Pellet LT 3D printers, which operate almost continuously to produce its custom furniture. Without the need to continuously develop, update and maintain its own 3D printing technology, Model No. has been able to double-down on its furniture business and can often deliver custom furniture orders in just 8 to 12 weeks.

3D Systems’ focus on 3D printing technology also means that machines and service parts are often available in inventory. When Model No. has needed additional machines, they have been available in just a week or two, Raub says. And, each printer can build the parts that may have been prototyped on another EXT Titan Pellet machine, bringing more redundancy to production.

Mediated Customized Design

Ceding 3D printer development to an outside partner has enabled Model No. to maintain focus on its mission to deliver custom furniture; interestingly, this attitude toward specialization is echoed in how the company’s customer-facing offerings have evolved as well. Today the parametric editor that once allowed buyers to tweak their furniture before ordering is gone from the company’s website, even though custom pieces are still the bulk of what Model No. does today.

Parametric design tools previously offered on the Model No. website proved engaging to visitors, but did not compel purchases. The company still offers customization, but now buyer choices are executed by its design team. (Click to expand)

“We found that people were playing with the tool online,” Raub says, “but they weren’t necessarily using it to purchase. It was a bit like asking someone to build their own car — you expect to have options, but don’t necessarily want to build the thing from scratch.”

Instead, the company has embraced its role as the design specialist, and shifted to an approach of mediated customization. Rather than an automated storefront, customers are now presented with color and material options, and invited to reach out to the company regarding their specific needs.

Furniture customization now takes place in CAD rather than the customer-facing editor. Source: Model No.

“We want to have that interaction and engagement with the customer,” Raub says. This more service-based approach also makes sense for the customer mix the company now serves. While individuals do still order furniture, most of Model No.’s business today is commercial contracts. Its team of internal designers works with the client to craft the right size, shape, and design for the space, whether it’s a corporate headquarters or hotel lobby.

“Customization is still core to the company,” Raub says, but now the responsibility for that customization has shifted back to Model No. and its internal team of designers.

Material Flexibility and Circularity

Since my previous interview with Model No. in 2020, the company has diversified its product offerings beyond tables and seating into lighting, office accessories and outdoor furniture. It has also added to its color and material options. Solid wood components are still manufactured from hardwoods certified by the Forest Stewardship Council (FSC) as well as local reclaimed wood. Furniture pieces use organic textiles and nontoxic finishes, sealants and adhesives. But the selection of 3D printable materials has expanded; more colors are available in the proprietary plant-based bioresins, and the company now offers a material that combines both resin and wood.

Wood shavings from the CNC cutting process were collected and compounded into a filled resin, which was then used to 3D print a coordinating stool (pictured).

Source: Model No.

This last option is the result of a collaborative project called “Endless Loop: From Waste to Wanted” that the company undertook in 2022. Model No. worked with PROWL Studios and Detroit based artist Mike Han to design and execute a fully circular, zero-waste set of pieces. Fallen ash trees were salvaged for lumber, which was cut to size via CNC milling. The sawdust from the process was then gathered, compounded with PLA into pellets, and used to 3D print additional pieces for the project.

Since then the company has added a 93% wood-filled PLA to its material catalog. The printed material has a wood-like appearance and is 93% biodegradable; it can also be printed faster than other resins, bringing some lead time and productivity advantages despite being more expensive than a straight polymer.

Wood-filled resin is now a commonly used material for Model No. for pieces such as this Bolster chair made for a commercial client. Source: Model No.

This type of material formulation and experimentation is a key interest for Model No. and another reason for adopting the Titan platform. The pellet-fed printer supports a more diverse range of materials than is currently available in filament format, and features a heated, enclosed chamber that can provide suitable printing conditions for many thermoplastics and composites.

“It’s very important to us that the end user can run the material they want,” says Rahul Kasat, who previously served as CEO at Titan Robotics and has been vice president at 3D Systems since 2022. The machine’s extruders, he says, were developed to be able to print hundreds of different materials — beyond even what is currently available today.

The extruders of the Titan printers are designed so that users “do not have to compromise on the functionality” of materials they use, according to Rahul Kasat. Source: 3D Systems

“We want users to be able to select materials for the end application, and not have to compromise on the functionality,” Kasat says.

That material flexibility will continue to be important as Model No. looks to the future. While most of the furniture materials used today are biodegradable, the company has always intended to provide recycling services as well. Right now the amount of product in use is low, and the furniture is proving durable enough that there is no immediate demand for a large scale takeback program. But developing workflows to grind used furniture back into pellets and 3D print with it for prototypes — if not production items — is still in the cards for the long term, Raub says. While work to close the loop on the circular economy for furniture will necessitate experimentation with both material and technology, Model No.’s focus will remain on its product.

“We’ve shown that there is a viable market for 3D printed furniture,” Raub says. “We’re still somewhat vertically integrated, but we’ve brought in partners who excel at their specialties. That lets us focus on pushing the machines and innovating our designs.”

Related Content

3D Systems Offers MJP 300W Printer, Wax Material for Advanced Jewelry Additive Manufacturing

The combination of the MJP 300W jewelry printer and VisiJet Wax Jewel Ruby enables jewelry designers to more efficiently achieve new designs with greater design freedom and improved surface finish.

Read MoreHP Works With Brooks Running to 3D Print Performance Footwear

HP has collaborated with Brooks Running to create the Brooks Exhilarate-BL which features 3DNA, a 3D-printed midsole technology that delivers a propulsive, bouncy ride.

Read More3D Printed Ductile Spikes for Better Sound Quality: The Cool Parts Show Bonus

Work on 3D printing flexible metal bellows has led to other applications, including the development of ductile spikes that sit between a speaker and the surface below to help limit vibration and isolate the audio equipment.

Read More3DEO Wins Design Excellence Awards

3DEO was recognized for outstanding applications of powder metallurgy.

Read MoreRead Next

Parametric Design and 3D Printing Deliver Custom, Sustainably Manufactured Furniture

Model No. operates at the intersection of technology and design. Its custom furniture is made on demand through a combination of proprietary large-format 3D printers, sustainable materials and a sleek online storefront.

Read More3D Printing Brings Sustainability, Accessibility to Glass Manufacturing

Australian startup Maple Glass Printing has developed a process for extruding glass into artwork, lab implements and architectural elements. Along the way, the company has also found more efficient ways of recycling this material.

Read MoreTo Improve Performance of Compression Molded Composites, Add 3D Printed Preforms

9T Labs' Additive Fusion Technology enables the manufacture of composite structures with as much or as little reinforcement as is necessary, using 3D printed continuous fiber preforms to add strength just where needed.

Read More

.jpg;width=70;height=70;mode=crop)

.jpg;maxWidth=300;quality=90)