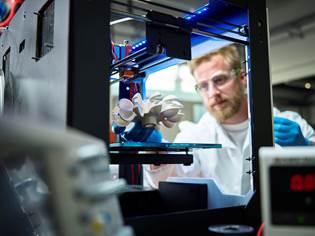

UL's independent research investigated the safety-critical performance properties of 3D printed samples against injection-molded samples. Researchers identified significant variations and concluded that performance ratings from traditional manufacturing techniques cannot be applied when the same material is used in 3D printing.

The findings have been used to develop an independent program for evaluating and qualifying plastics intended for 3D printing, helping AM stakeholders mitigate risk and deliver quality and performance.

Primary Topics:

- Effects of 3D printing on ignition, flammability, and dielectric strength

- Applying pre-selection of materials for faster product compliance

- The Blue Card explained – plastics used for additive manufacturing

- Certifying 3D-printed products and components

Presenter:

Kenneth R. Vessey, Jr.

Senior Staff Engineer, UL

Kenneth is a Distinguished Member of Technical Staff at Underwriters Laboratories. Ken has more than 30+ years of UL certification experience and is presently a corporate presenter for UL University for “Plastics for Use in Electrical and Electronic Applications”. He is an integral part of the development of the Recognition Program for Plastics Materials used in Additive Manufacturing (AM) and is a member of ASTM F42/ ISO TC 261 on AM. Ken is also responsible for providing global technical assistance to UL's engineers handling certification projects for materials and electronic end products.