Thinking “Inside Out” and “Outside In”

The mindset for additive flips subtractive thinking inside out.

Addition and subtraction are diametrically opposed. The former increases value by adding something of more value while the latter reduces the value of something by taking away from the original whole — at least in a mathematical sense.

In reality, though, people use subtraction all the time to increase the value of something. Sculptors create priceless statues from blocks of marble by carefully removing material. Woodworkers make beautiful furniture by carving away pieces of wood. Even Mother Nature subtracts, using rivers, for example, to erode the surrounding landscape to create beautiful scenery that people often pay to enjoy.

Machining professionals are masters of subtraction. They create parts and products that we value by removing unwanted sections from a larger billet of material. Like sculptors, they can see the final part hidden inside a block of metal and conceive of the tooling and fixturing needed to reveal it. I can imagine the internal dialogue as a manufacturer is presented a new part to make: “If I hold it this way, then I can machine that face and cut that away so that when I flip it and hold it here to ream that hole…” and on and on until the final part is obtained.

So how do you teach this subtractive mindset, or “outside-in” thinking? In schools, we teach students how to read and interpret 2D views and orthographic projections of the part, and then introduce them to subtractive manufacturing methods and tools, such as milling and lathes, via lectures, videos and hands-on labs. In industry, these skills are learned on the job and honed through years of practice and apprenticeships, much like young Padawans learn the force from more seasoned Jedi. (Sorry, couldn’t resist — huge Star Wars fan!)

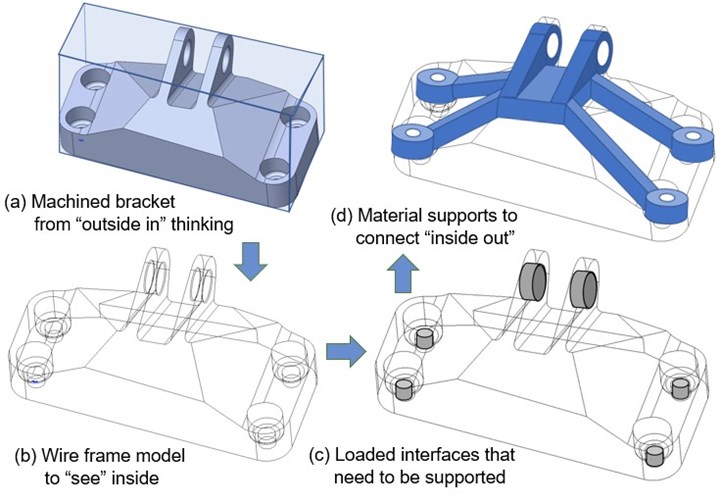

Example of shifting mindset from “outside in” to “inside out” thinking for a machined bracket from GE Bracket Challenge. It is inspired by Nigel Southway’s “wire frame thinking” figure on page 12 in the 2017 Canadian AM Guide published by Design Engineering.

Educational games have emerged to teach these skills. For example, Cube Cut from Simcoach Games is available for free on Android and Apple phones and products, and it is a fun and interactive app to learn about machining. Through a series of levels, you learn how to subtract material away from a solid block to make increasingly complex shapes and features. The Simcoach Games team has done a great job gamifying the learning process for subtractive manufacturing, and it is even starting to attract young people to consider jobs in manufacturing.

Topology optimization is in this same vein, as I discussed last month. Recall that topology optimization software uses computer algorithms to subtract material away in an existing part to make it lighter weight, for example. It mimics the outside-in mindset, and there are fun and interactive apps to learn topology optimization as well, such as TopOpt and TopOpt3D. Using these helps people visualize how a part can be made lighter without affecting its strength.

Additive manufacturing flips the subtractive mindset inside out. Instead of removing material to reveal a part from a larger billet, your thinking shifts to adding material from the interior, working your way to the outside boundary. You start by asking where and how much material does the part need to support the forces and loading it experiences or channel the fluids that may run inside it or dissipate the heat that builds up from within? Then you think about features or surfaces that need to be protected or enclosed, mating interfaces to attach other components and the additional loads or constraints that those connections impose. The list goes on as it is imperative to consider all aspects of how the part will be used when thinking this way.

Sixteen examples illustrating “inside-out” thinking from hundreds of designs submitted to the GE Bracket Challenge (Available via GrabCAD).

This “inside-out” thinking is akin to growing a part, much like living organisms grow. This is why people often seek inspiration from nature when designing for additive manufacturing. In fact, websites like asknature.org allow you to search through over 2,000 biological strategies and innovations in nature to learn how different living organisms and creatures have evolved solutions to survive. The number of solutions that nature has evolved to manage impact, for example, is fascinating.

I think my inside-out mindset resulted from years of building LEGO, starting with a single brick or plate and building a complex and elaborate structure that can be used as a toy without breaking. A great example is the huge AT-AT set that stands over two feet tall and walks on articulating legs without breaking (as I said, huge fan).

Kids these days playing Minecraft build houses, cities and entire worlds one “brick” at a time. As I watch my children play, switching from one type of brick to another, I can’t help but think how we might extend Minecraft to designing parts, one block of material at a time, starting from the inside and working out, adding different material in different regions of the structure to achieve different functions. Several additive manufacturing technologies give us some level of control during deposition — material jetting and directed energy deposition both spring to mind — but designing such parts in CAD software remains challenging.

This is where generative design software is giving rise to new algorithms and tools to help. Just imagine how long it would take to design and build an entire airplane, for example, brick by brick as if building LEGO or playing Minecraft. I can’t wait to be able to do that though!

Software tools will continue to evolve to nurture and support the inside-out mindset that helps users think additively, but don’t misunderstand. I am not arguing one mindset should replace the other, just like I will not argue that additive manufacturing will entirely replace subtractive manufacturing. It has never been an either/or scenario; it needs to be both, and that is the real mindset that we need to cultivate in manufacturing these days.

Related Content

Looking to Secure the Supply Chain for Castings? Don't Overlook 3D Printed Sand Cores and Molds

Concerns about casting lead times and costs have many OEMs looking to 3D print parts directly in metal. But don’t overlook the advantages of 3D printed sand cores and molds applied for conventional metal casting, says Humtown leader.

Read MoreTo Grow Additive Manufacturing Adoption, HP Is Aiming for the C-Suite

3D printing has been largely the purview of service bureaus and technical specialists but HP sees a future where it is increasingly the concern of OEM executives — and the company is taking steps to reach them.

Read MoreA Framework for Qualifying Additively Manufactured Parts

A framework developed by The Barnes Global Advisors illustrates considerations and steps for qualifying additively manufactured parts, using an example familiar to those in AM: the 3D printed bottle opener.

Read More5 Big Themes in Additive Manufacturing at Formnext Forum: Austin

Formnext Forum: Austin, a two-day event at the end of August focused on additive manufacturing for production, includes a conference exploring important ideas in AM related to supply chains, bridge production, enterprise transformation and more.

Read MoreRead Next

Video: Is Additive Manufacturing a Competitor to CNC Machining?

Not at all, says Renishaw’s Robert Chiari. The manufacturing methods complement one another, which is why many machining facilities are looking to AM.

Read MoreAt General Atomics, Do Unmanned Aerial Systems Reveal the Future of Aircraft Manufacturing?

The maker of the Predator and SkyGuardian remote aircraft can implement additive manufacturing more rapidly and widely than the makers of other types of planes. The role of 3D printing in current and future UAS components hints at how far AM can go to save cost and time in aircraft production and design.

Read More3D Printing Brings Sustainability, Accessibility to Glass Manufacturing

Australian startup Maple Glass Printing has developed a process for extruding glass into artwork, lab implements and architectural elements. Along the way, the company has also found more efficient ways of recycling this material.

Read More

.png;maxWidth=300;quality=90)