Renishaw Metal AM Enables Domin to Create CO2-Reducing Valve

By using Renishaw’s RenAM 500Q AM system, Domin has created a servo valve that saves one ton of CO2 per year compared to competing products.

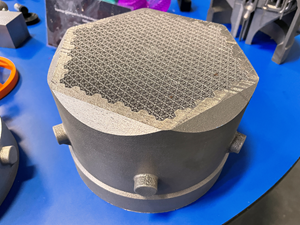

Renishaw’s RenAM 500Q gave Domin the design freedom to reduce CO2 emissions from its servo valves — approximately one ton per year for each valve.

Photo Credit: Renishaw

Domin has used metal additive manufacturing technology from Renishaw to develop a range of efficient servo valves, and is now setting out to showcase how engineering start-ups can drive value for UK industry. Domin has produced what it says is a first-of-its kind product — a high-performance servo valve. Such innovation represents the company’s first step towards drastically reducing CO2 emissions from the fluid power industry, as every valve can save one ton of CO2 annually.

Disruption Through AM

Domin aims to disrupt the fluid power industry by improving the range of technology available and increasing sustainability. Although recent decades have seen swathes of technology introduced across all industries, Domin believes there has not yet been an innovation that has caused significant enough change in the fluid power market.

For Domin, metal additive manufacturing (AM) was the missing piece of the puzzle, and it turned to this technology to design its product range. By using the Renishaw RenAM 500Q, a four-laser AM system designed for serial production applications, Domin was able to increase its productivity, achieve design freedom and reduce cost per part in such a way that 3D printing presented a compelling case for use in hydraulic manufacturing.

Spurring Change

“There is a pressing reason disruption is needed — sustainability,” says Marcus Pont, CEO of Domin. “In the US, the fluid power sector alone wastes about 300 million tons of CO2 per year through system inefficiencies. To put this into context, this is about the same as the total output for all CO2 emissions in the UK. More efficient technology could make a real difference to global emissions.”

“Britain is home to some of the world’s leading engineering businesses,” Pont adds. “However, most of the UK’s big engineering businesses were started in the 20th century. It’s time for British business to become more ambitious. Combining metal additive manufacturing with other technologies revolutionizes what can be achieved technically — it could generate real value for British industry.”

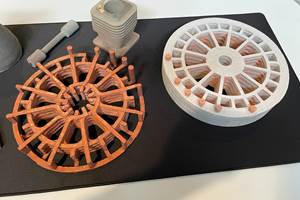

Domin says its servo valves are only the first step in its plans. Long term, the company plans to manufacture and sell complete systems. Photo Credit: Renishaw

New Markets

“Additive manufacturing is proving to be a key enabler in many markets,” says Bryan Austin, director of sales, additive manufacturing group at Renishaw. “The productivity that Renishaw’s technology enables means metal 3D printing is broadening into markets where it was previously uneconomical. Domin has showcased how AM can be used to make products better, faster and cheaper than traditional manufacturing would allow.”

Domin designed its electrohydraulic valves for demanding servo applications, and markets them as small, light, affordable and high-performance products that are easy to configure online while offering good power density and dynamic performance. Pont sees this product range as just the first step in creating change in fluid power systems across the UK, as “every valve saves over one ton of CO2 per year compared with alternative products.”

Related Content

3D Printed Heat Exchanger Illustrates Siemens' CATCH and Release Approach

Solutions for energy efficiency, sustainability, part repair and more are developing at Siemens’ Charlotte Advanced Technology Collaboration Hub (CATCH) in North Carolina.

Read MoreCopper, New Metal Printing Processes, Upgrades Based on Software and More from Formnext 2023: AM Radio #46

Formnext 2023 showed that additive manufacturing may be maturing, but it is certainly not stagnant. In this episode, we dive into observations around technology enhancements, new processes and materials, robots, sustainability and more trends from the show.

Read MoreConcept Sneaker Boasts One-Piece 3D Printed TPU Construction

The Reebok x Botter Concept Sneaker Engineered by HP premiered at Paris Fashion Week, hinting at manufacturing possibilities for the future of footwear.

Read MoreMultimaterial 3D Printing with Conventional Powder Metallurgy

Unbound sand serves as temporary, reusable molds for metal powders in Grid Logic’s 3D printing process.

Read MoreRead Next

Materialise Powder, Prototyping Platform Empower Sustainability

Bluesint PA 12 powder makes it possible to print with up to 100% reused powder, while Process Turner online platform speeds up prototyping process to eliminate waste.

Read MoreFuture-Proof Additive Manufacturing Debinding Through Sustainable Methods

Sustainable manufacturing can increase operational efficiency while responding to environmental requirements, but must consider the entire production chain including postprocessing. For binder jetting, this means selecting a sustainable debinding method.

Read MoreAdditive Manufacturing and Sustainability Go Together — Here Is Why

3D printing enables sustainable production through recycled materials, end-of-product-life-cycle solutions, and helping to realize eco-friendly products.

Read More

.png;maxWidth=300;quality=90)