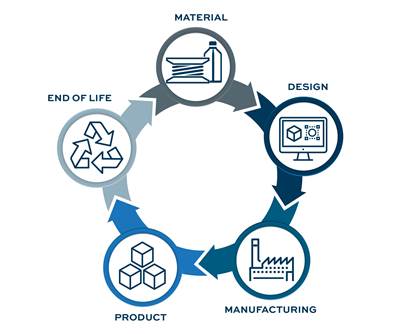

Editor’s note: Additive manufacturing is potentially a more sustainable production method than conventional ones, but only if the entire process is taken into account. 3D printing may be able to build a lighter, more efficient component using less material; however, these benefits might be offset by factors such as large amounts of energy used in the build or waste generated from postprocessing. This contributed piece looks at sustainable options for one post-print operation, debinding the green parts created in binder jetting processes. —Stephanie Hendrixson, Senior Editor

The most successful manufacturers understand that environmental responsibility is an integral part of their business. To be sustainable, manufacturing requires a reduction in energy use, water use, emissions and waste generation. AM is an important development in reaching this goal. Metal AM produces less material waste than conventional manufacturing methods. Energy use is also reduced, together with a lower carbon footprint thanks to localized production and the necessity for less material transport and handling.

However, it is essential to remember that it is the entire process that needs consideration for sustainability. For binder jetting and similar 3D printing processes, this includes the parts debinding and cleaning methods, and the fluids used in those steps.

During the binder jetting process, green parts are built by depositing a mixture of ultrafine metal powder and a binding agent onto a build plate in successive layers. Common types of binders include paraffin wax, carnauba wax and specialty polyethylene waxes. The binding agents serve the important purpose of holding the resulting 3D printed green part together prior to sintering. Once the green part is printed, it is debound and then sintered into its final mass state.

Although the binder is critical to forming the metal powder into a specific shape, a percentage of this agent must be selectively removed from the internal structure of the part before the green part can be exposed to the high heat required for the next step of sintering. Removal of the binders significantly reduces the sintering time, but it is important to strike a balance of removing exactly the right amount of binder as quickly as possible without damaging the fragile parts.

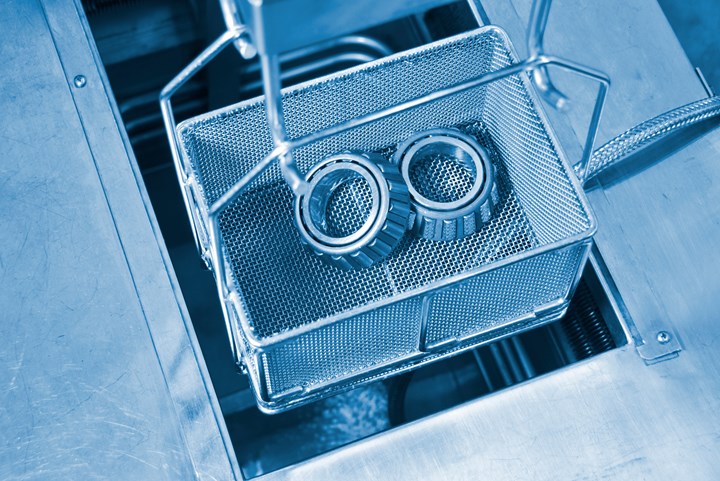

To achieve a quality finish and guarantee reliability and quality, any parts produced using AM should be cleaned effectively and the binders removed both efficiently and sustainably. The most effective way to do this is through vapor degreasing and the use of novel debinding fluids.

Vapor degreasing (pictured) coupled with novel debinding fluids is a more sustainable process for finishing metal parts made with binder jetting 3D printing. Image Credits: MicroCare

Environmental Benefits of Vapor Degreasing

New, sustainable, debinding fluids have been formulated to remove binders quickly, safely and cost-effectively, and without worker or environmental implications. These fluids applied to vapor degreasing can be a greener debinding option than other methods.

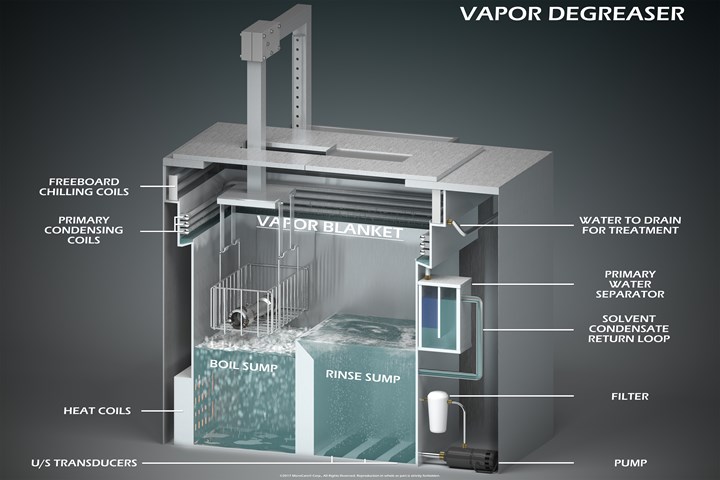

Unlike aqueous cleaning, vapor degreasing uses no water, therefore conserving this resource. It also requires less power to run than most aqueous cleaning machines, reducing fossil fuel consumption. Additionally, it does not produce wastewater that requires specialty filtration, distillation, deionization and osmosis prepping prior to disposal, another environmental benefit.

Vapor degreasing using novel debinding fluids cleans and debinds parts effectively.

In use, modern vapor degreasing fluids pose fewer air quality concerns than legacy solvents such as n-propyl bromide (nPB), trichloroethylene (TCE) and perchloroethylene (PERC). Most modern debinding fluids have a very low global warming potential (GWP) which helps reduce greenhouse gas effects. They also typically have a zero ozone depleting potential (ODP ) and a low volatile organic content (VOC), and can meet strict regional air quality regulations. There are also many vapor degreasing fluids that are not deemed to be hazardous air pollutants (HAPs). Furthermore, these innovative fluids meet global environmental regulations including North American NESHAP standards and European F-Gas and REACH (Registration, Evaluation, Authorisation and Restriction of Chemicals) legislation. Importantly, they offer improved eco-friendly properties without compromising their performance.

Another environmental benefit of debinding AM parts through a vapor degreasing system is its capacity for continuous recovery and recycling. The debinding fluid used within it can be used and recycled many hundreds of times before it needs refreshing or replacing. When it is time for disposal, the vapor degreaser concentrates the soil, contaminants and binders pulled from the green parts, minimizing the amount and frequency of waste disposal.

For companies using AM, looking for help in selecting and using sustainable debinding fluids is essential. It is therefore important to work with a partner with expertise in this area who can recommend long-term, reliable and environmentally-advanced debinding fluids and methods that will work effectively.

About the Author

Venesia Hurtubise is a technical chemist at MicroCare LLC, which offers precision cleaning solutions. She has been in the industry more than 6 years and holds a M.S. in green chemistry from Imperial College. Hurtubise researches, develops and tests cleaning-related products that are used on a daily basis in precision cleaning and medical applications. For more information, visit microcare.com.

Related Content

Copper, New Metal Printing Processes, Upgrades Based on Software and More from Formnext 2023: AM Radio #46

Formnext 2023 showed that additive manufacturing may be maturing, but it is certainly not stagnant. In this episode, we dive into observations around technology enhancements, new processes and materials, robots, sustainability and more trends from the show.

Read MoreGE Additive Helps Build Large Metal 3D Printed Aerospace Part

The research is part of an initiative to develop more fuel-efficient air transport technologies as well as a strong, globally competitive aeronautical industry supply chain in Europe.

Read MoreAdditive Wins on Cost, Plus Process Monitoring and More from RAPID + TCT 2023: AM Radio #38

Additive manufacturing is finding success as a cost-effective manufacturing method. New options for process monitoring are now available. DED is getting more precise. 3D printed chairs! What we learned and observed at RAPID + TCT 2023.

Read MoreNext-Gen Horse Trailers to Be Built With Robotic 3D Printing

Double D Trailers is currently developing a prototype horse trailer that will be made with large-format additive manufacturing. The technology brings potential benefits for labor, weight and design features to this subset of recreational vehicles.

Read MoreRead Next

3D Printing with Postprocessing in Mind

3D printing requires different finishing considerations than traditional manufacturing. One expert offers do’s and don’ts for approaching the finishing of additively manufactured parts.

Read MoreHow to Choose a Debinding Fluid for Metal 3D Printing

Binder jetting and feedstock extrusion depend on binders that are ultimately sacrificial. MicroCare offers factors to consider in selecting a debinding fluid for these metal additive manufacturing processes.

Read MoreSustainability’s Moment Is Additive Manufacturing’s Moment

The disruption needed by additive manufacturing closely mirrors that required to implement the circular economy. Both can be pursued simultaneously — and the right time is now.

Read More