Removing Metal Supports from AM Parts

What is the best way to remove metal support structures from AM parts?

Assuming you’ve already taken the necessary precautions that will allow you to safely handle parts additively built from metallic powder and feedstock, your next question likely is: What is the best method for removing their metal support structures? For parts manufactured in laser-based powder-bed systems, those support structures will be of the same material as the part itself, whether that is a titanium alloy such as Ti-6Al-4V (Ti64) or a nickel chromium alloy like Inconel 718.

Logic might dictate that you use the same feeds and speeds to machine away the support structures as you would to machine any other part made from these materials, but the jury is still out on this case for two important reasons:

1) In subtractive machining, you start with a material that has the properties you want and then create the shape you want from it. In additive manufacturing, it is the reverse: You build the shape you want and then heat treat, age and solution-anneal the material to get the properties you want. So depending on the postprocessing heat treatment (or lack thereof), the microstructure of an additive part will vary, which means you may not be post-machining the grade of material you think you are. In short, you will not know exactly what material you are machining when you are removing metal support structures from an AM part.

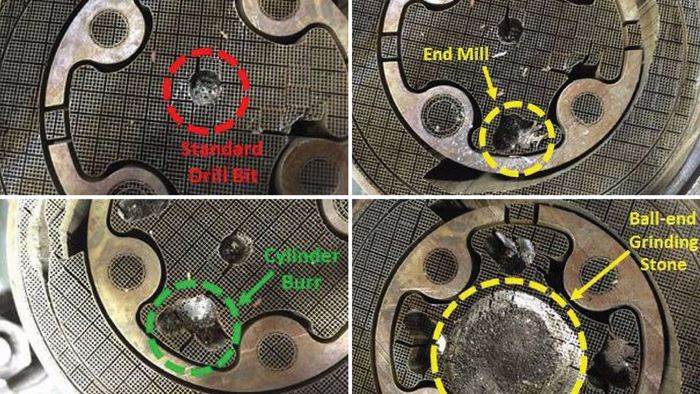

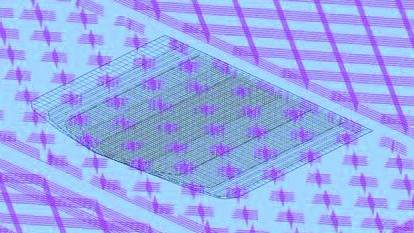

2) Support structures are often hollow, which means you are not continuously machining metal as you cut through them. The images in Figure 1 show what you will likely encounter: a thin-walled, mostly solid support, then air, then another thin wall, then air, and so on. Furthermore, most supports are not fully dense, particularly in the build direction. Since the supports will be removed from the finished part, it seems unnecessary to make them fully dense, so laser-path planning algorithms often skip every other layer of the supports, saving material and reducing build time. Figure 2 shows the hatch spacing (laser-scan path) for a part and its supports. The tightly spaced gray lines represent the laser path for the part, while the sparser pink lines indicate the laser path for the supports. The tighter hatch spacing yields a fully dense part, while the coarser spacing will lead to slightly porous supports.

Figure 1 also illustrates the challenges in removing internal support structures by different machining methods. These images were taken by a capstone engineering design team at Pennsylvania State University that was tasked with finding ways to remove the supports from a stainless steel piston crown. As you can see by the top left image, a standard drill was fairly ineffective, crushing the supports inward instead of removing them. The end mill (top right) and ball-end grinding stone (bottom right) were only slightly more effective, still tending to crush/tear the supports away versus cleanly removing them. As shown in the bottom left image, it was the cylinder burr that seems to have done the best job on this material and support-structure geometry, removing the supports cleanly as it plunged into the stainless steel thin-walled structures. Had the part been heat treated or made from a different material, or had a different support geometry been used, the results likely would not have been the same, and a different tool/approach would likely have faired better.

In summary, machining away metallic supports remains a challenge for additive manufacturing. While most researchers have focused on gaining a better understanding of the additive manufacturing process itself, few have spent the necessary time and energy to understand what it takes to remove support structures and finish additively manufactured parts efficiently and effectively. In many cases, service bureaus offering AM capabilities do not have postprocessing and finishing capabilities in house or may not be asked (or inclined) to remove support structures from a part. For those of you that have both additive and subtractive capabilities, or an interest in contributing to the postprocessing of additively manufactured parts, we desperately need your help.

This article originally appeared in Additive Insights, a monthly column in Modern Machine Shop magazine.

Related Content

Understanding HP's Metal Jet: Beyond Part Geometry, Now It's About Modularity, Automation and Scale

Since introducing its metal binder jetting platform at IMTS in 2018, HP has made significant strides to commercialize the technology as a serial production solution. We got an early preview of the just-announced Metal Jet S100.

Read MorePostprocessing Steps and Costs for Metal 3D Printing

When your metal part is done 3D printing, you just pull it out of the machine and start using it, right? Not exactly.

Read MoreWhat is Powder Bed Fusion 3D Printing?

Whether in metal or polymer, with a laser or an electron beam, powder bed fusion (PBF) is one of the most widely used 3D printing techniques.

Read MoreHow to Improve Polymer AM Productivity 20X

A fast cycle time is critical to efficient production 3D printing, but it’s not the only thing. How you choose the right parts for AM, prepare jobs for production, and manage post processing will have just as big an impact on total 3D printing throughput. It all needs to work together to achieve maximum productivity.

Read MoreRead Next

3D Printing Brings Sustainability, Accessibility to Glass Manufacturing

Australian startup Maple Glass Printing has developed a process for extruding glass into artwork, lab implements and architectural elements. Along the way, the company has also found more efficient ways of recycling this material.

Read MoreAt General Atomics, Do Unmanned Aerial Systems Reveal the Future of Aircraft Manufacturing?

The maker of the Predator and SkyGuardian remote aircraft can implement additive manufacturing more rapidly and widely than the makers of other types of planes. The role of 3D printing in current and future UAS components hints at how far AM can go to save cost and time in aircraft production and design.

Read MoreHybrid Additive Manufacturing Machine Tools Continue to Make Gains (Includes Video)

The hybrid machine tool is an idea that continues to advance. Two important developments of recent years expand the possibilities for this platform.

Read More

.png;maxWidth=300;quality=90)