Machining

How Machining Makes AM Successful for Innovative 3D Manufacturing

Connections between metal 3D printing and CNC machining serve the Indiana manufacturer in many ways. One connection is customer conversations that resemble a machining job shop. Here is a look at a small company that has advanced quickly to become a thriving additive manufacturing part producer.

Peter Zelinski

Editor-in-Chief, Additive Manufacturing

AM Workshops: The 3D Printing Conferences at NPE and IMTS 2024

We are presenting half-day conferences on additive manufacturing at both of the two largest manufacturing events in North America this year. Join us!

Read MoreHybrid Additive Manufacturing Machine Tools Continue to Make Gains (Includes Video)

The hybrid machine tool is an idea that continues to advance. Two important developments of recent years expand the possibilities for this platform.

Read More5 Points You Might Not Know About Hybrid CNC Machine Tools

Hybrid Manufacturing Technologies’ co-founder describes the role of hybrid additive manufacturing machines, and explores their possibilities related to heat treating, multimaterial tooling and making parts with embedding sensing.

Read MoreZeda AM Production Plant in Ohio Now Open — Thoughts on the New Facility

73,000-square-foot metal powder bed fusion plant includes extensive machining capability plus separate operational models for serving medical versus other businesses.

Read MoreThe Rise of AM Factories, Metal 3D Printing, Machining Synergy and Favorite Stories from 2023: AM Radio #47

Additive Manufacturing Media editors reflect on the top 10 stories by pageviews and then share their favorites, regardless of ranking, in this podcast episode.

Read MoreTop 10 Additive Manufacturing Stories of 2023

Laser powder bed fusion, proprietary AM processes, machining and more made our list of top 10 articles and videos by pageviews this year.

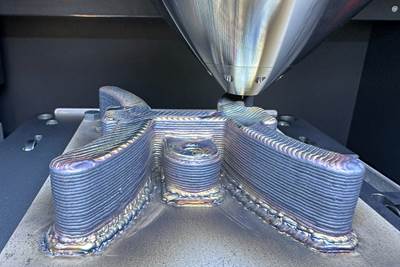

Read MorePush-Button DED System Aims for Machine Shop Workflow in Metal AM

Meltio M600 metal 3D printer employs probing, quick-change workholding and wire material stock to permit production in coordination with CNC machines.

Peter Zelinski

Editor-in-Chief, Additive Manufacturing

8 Cool Parts From Formnext 2023: The Cool Parts Show #65

New additive manufacturing technologies on display at Formnext were in many cases producing notable end-use components. Here are some of the coolest parts we found at this year’s show.

Read MoreWhen Additive and Conventional Processes Work Together, the Result Is Manufacturing

Various recent articles demonstrate 3D printing and established processes finding one another and working together.

Read MoreDMG MORI: Build Plate “Pucks” Cut Postprocessing Time by 80%

For spinal implants and other small 3D printed parts made through laser powder bed fusion, separate clampable units resting within the build plate provide for easy transfer to a CNC lathe.

Read MorePart Removal Efficiency In a 600 mm Plus World

Clay Olson of EDM Performance Accessories discusses the difficulties and opportunities in cutting off parts from the build plates of large AM systems. Molybdenum wire EDM offers an effective solution to the challenge of large-part cutoff.

Read MoreATI to Establish Additive Manufacturing Facility to Serve US Navy

ATI will utilize its metal additive manufacturing and machining capabilities as part of contract with Bechtel Plant Machinery Inc. (BPMI) to support the U.S. Navy.

Read MoreResearch Partners 3D Print MIM Tool With Near-Contour Cooling

Compared to a conventional approach in machining, the use of an additive manufacturing process to produce a MIM tool reduces the total production time from around 8 weeks to approximately 5 days.

Read More6 Cutting Tools for Machining Made Via 3D Printing

By making tools, additive manufacturing aids so-called “subtractive” manufacturing (better known as machining). Here are examples of how 3D printing balances performance, coolant flow and weight in small and large cutting tools.

Peter Zelinski

Editor-in-Chief, Additive Manufacturing

How Norsk Titanium Is Scaling Up AM Production — and Employment — in New York State

New opportunities for part production via the company’s forging-like additive process are coming from the aerospace industry as well as a different sector, the semiconductor industry.

Read MoreSeurat: Speed Is How AM Competes Against Machining, Casting, Forging

“We don’t ask for DFAM first,” says CEO. A new Boston-area additive manufacturing factory will deliver high-volume metal part production at unit costs beating conventional processes.

Read MoreVulcanForms Is Forging a New Model for Large-Scale Production (and It's More Than 3D Printing)

The MIT spinout leverages proprietary high-power laser powder bed fusion alongside machining in the context of digitized, cost-effective and “maniacally focused” production.

Read MoreNew Zeda Additive Manufacturing Factory in Ohio Will Serve Medical, Military and Aerospace Production

Site providing laser powder bed fusion as well as machining and other postprocessing will open in late 2023, and will employ over 100. Chief technology officer Greg Morris sees economic and personnel advantages of serving different markets from a single AM facility.

Read MoreResearchers Examine Additive-Subtractive Manufacturing Process Chain

Researchers on the Advanced Processing of Additively Manufactured Parts project examined the additive-subtractive manufacturing process chain to optimize workpiece properties (such as geometry, surface and subsurface characteristics) throughout the entire process chain.

Read MoreSoniclayer 1600 Combines Ultrasonic 3D Printing With CNC Milling

The printer features an ultrasonic additive manufacturing 3D printing process which generates very little heat, making it possible to embed electronics, fiber optics, sensors and other components inside these prints.

Read MoreCumberland Additive: EBM Development and AM Community Among the Benefits at Neighborhood 91

“Digital transparency” is key, says regional director Mark Straszheim, as employees oversee resources in both Pennsylvania and Texas.

Peter Zelinski

Editor-in-Chief, Additive Manufacturing

Nicolet Plastics Succeeds Using Mantle's Hybrid Metal 3D Printing Method for Mold Tooling

A recent webinar explores Nicolet Plastics’ success using Trueshape Technology, Mantle’s approach to print injection mold tooling. The current challenges this technology addresses and alleviates in additive manufacturing confirms this method is effectively reducing lead times and cost constraints, while producing better inserts.

Read MoreSuccess With AM Involves Not Just the Part but Also Its Purpose

The founder of Keselowski Advanced Manufacturing says additive makes the conversation with the contract manufacturer different from the beginning.

Read More3D Printed Cutting Tool for Large Transmission Part: The Cool Parts Show Bonus

A boring tool that was once 30 kg challenged the performance of the machining center using it. The replacement tool is 11.5 kg, and more efficient as well, thanks to generative design.

Read MoreThe Robot Craftsman: Force Sensing and Vision Help Realize Automated AM Postprocessing (Includes Video)

Automated production via additive manufacturing will need automated postprocessing. This UK startup is equipping robots with the capabilities needed for critical, fine-detail finishing of metal 3D printed parts.

Read MoreAdditive Manufacturing Is Subtractive, Too: How CNC Machining Integrates With AM (Includes Video)

For Keselowski Advanced Manufacturing, succeeding with laser powder bed fusion as a production process means developing a machine shop that is responsive to, and moves at the pacing of, metal 3D printing.

Read MoreIs Every 3D Printed Replacement Part Inherently an Upgrade? AM Radio #32

Additive manufacturing is a powerful tool for replacement parts, but turning to AM offers opportunities beyond recreating what came before. In this episode of the AM Radio podcast, we discuss AM for repair, replacement and upgrades.

Read More