Velo3D’s Flow 5.0 Software Enhances Control Over 3D Printing Process

The software’s new features include user-selectable core parameters, preprint analysis to identify potential costly and time-consuming errors, and rapid resequencing for multipart prints.

Share

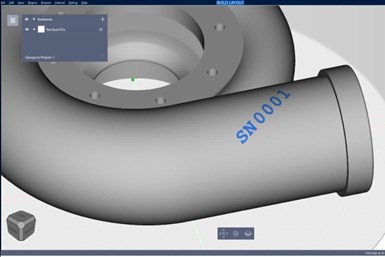

With the new labeling module in Flow 5.0, users can quickly add text to the print file, enabling serialization of parts or other identifying marks. Photo Credit: Velo3D

Velo3D, a metal additive manufacturing (AM) technology company for mission-critical parts, has updated its Flow print preparation software. Flow 5.0 was developed to unlock an array of new capabilities for engineers using Velo3D’s fully integrated solution, including user-selectable core parameter sets that provide enhanced control over builds with the ability to assign different parameters to any part on the build plate. This improvement, in addition to Flow’s ability to apply skin and contour overrides, gives customers enhanced control over the final material properties of printed parts.

“Through our software, we are able to continually expand our manufacturing capabilities based on customers’ needs and feedback,” says Alexander Varlahanov, vice president of engineering at Velo3D. “By enabling selectable core parameters for customers, engineers can modify the material properties of their parts to better suit the need of the application, including more isotropic parts. This even works on builds with multiple types of parts where each requires a different core parameter set.”

Flow 5.0 includes checks and messages that identify possible errors before a build even starts, reducing the likelihood of customers experiencing failures in their builds. In doing so, engineers can be confident that a part will print successfully before the process begins. Flow also includes labeling for objects. Customers can easily add alphanumeric characters, such as serial numbers or other unique identifying text, to their builds within the Flow print preparation software to clearly identify and label instances of their parts. Once the print file is produced, the characters can be updated through a Label Updater tool.

The release also enables a faster method to calculate build times for builds of different part quantity. After a part has been prepared for print, users can vary the quantity of that part and see updated build times to better understand the economics of scaled production. This enables contract manufacturers to speed up their quoting process and accelerate OEM planning and scheduling.

The Flow print preparation software is a key part of Velo3D’s fully integrated metal AM solution. The software takes traditional CAD files and turns them into print files without any specialization or design for additive manufacturing (DfAM). Other parts of the solution include the Sapphire family of printers, Assure quality assurance software, and the underlying Intelligent Fusion manufacturing process that ensures consistent, repeatable outcomes across different Sapphire printers from the same print file.

- Read about Visser Precision joining Velo3D’s Global Contract Manufacturing Network after purchasing and receiving two Velo3D Sapphire printers to expand its additive manufacturing capabilities for its aerospace customers.

- Learn about Zeda’s new additive manufacturing factory in Ohio which will provide medical, military and aerospace production. The site features laser powder bed fusion machines from Velo3D.

- Check out this post about 3D printed metal parts going hypersonic at zero mph. Purdue Researchers are using additively manufactured injector components from Velo3D to create Mach 6 conditions for a ground-testing facility.

Related Content

Formnext 2022: Ceramics, Robots and Other Perspectives From Near and Far: AM Radio #30

The 2022 edition of Formnext revealed more options and applications for 3D printed ceramics, anticipation of coming automation, established companies entering AM and more. Two editors — one present at the show, and one observing from a distance — compare notes in this episode of AM Radio.

Read MoreSolving 3D Printing’s Hidden Problem: Vibration

Ulendo’s vibration compensation software can double the speed of FFF 3D printers while maintaining part quality, all without changing the machine’s hardware.

Read More3D Printed Cutting Tool for Large Transmission Part: The Cool Parts Show Bonus

A boring tool that was once 30 kg challenged the performance of the machining center using it. The replacement tool is 11.5 kg, and more efficient as well, thanks to generative design.

Read MoreCopper, New Metal Printing Processes, Upgrades Based on Software and More from Formnext 2023: AM Radio #46

Formnext 2023 showed that additive manufacturing may be maturing, but it is certainly not stagnant. In this episode, we dive into observations around technology enhancements, new processes and materials, robots, sustainability and more trends from the show.

Read MoreRead Next

Hybrid Additive Manufacturing Machine Tools Continue to Make Gains (Includes Video)

The hybrid machine tool is an idea that continues to advance. Two important developments of recent years expand the possibilities for this platform.

Read More3D Printing Brings Sustainability, Accessibility to Glass Manufacturing

Australian startup Maple Glass Printing has developed a process for extruding glass into artwork, lab implements and architectural elements. Along the way, the company has also found more efficient ways of recycling this material.

Read MoreAt General Atomics, Do Unmanned Aerial Systems Reveal the Future of Aircraft Manufacturing?

The maker of the Predator and SkyGuardian remote aircraft can implement additive manufacturing more rapidly and widely than the makers of other types of planes. The role of 3D printing in current and future UAS components hints at how far AM can go to save cost and time in aircraft production and design.

Read More

.png;maxWidth=300;quality=90)