Mantle’s High-Precision Shaping for Automating Precision Toolmaking

The High-Precision Shaping feature expands the capabilities of Mantle’s hybrid metal 3D printing technology, enabling finer feature creation and dramatically expanding the geometries compatible with its TrueShape process.

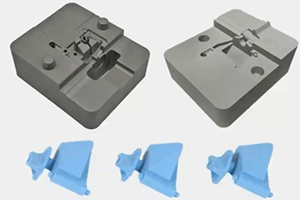

Mantle’s High-Precision Shaping package prints features that would require extensive EDM to produce via traditional manufacturing. Photo Credit: Mantle

Mantle, a provider of metal 3D printing for toolmaking, has updated its TrueShape Software with new High-Precision Shaping capabilities, as it continues to deliver a turn-key system with no CAM programming required. The High-Precision Shaping package includes 0.006" and 0.010" ball mill cutting tools and automated toolpathing software.

The package expands the capabilities of Mantle’s hybrid metal 3D printing technology, enabling finer feature creation and dramatically expanding the geometries compatible with its TrueShape process. It also enables tool rooms to automate their toolmaking process by producing sharp corners and edges without requiring EDM operations.

The new cutting tools (including the .006” and .010” ball mill cutting tools) enable radii under 0.003", which is comparable to sinker EDM. By eliminating EDM and other toolmaking operations, Mantle says it helps tool rooms reduce the time required to produce mold tools by up to 75%.

“At Mantle, our goal is to help tool rooms increase the number of complex mold tools they produce while reducing the time, cost and labor to produce them,” says Ted Sorom, Mantle CEO and co-founder. “By deploying our new High-Precision Shaping capabilities, our customers can produce steel tools faster than ever — without requiring programming, setup and operator time from overworked toolmakers.”

Mantle says its TrueShape technology combines 3D printing of its tool steel pastes with traditional CNC machining to refine the shape of printed tools and deliver accuracy, surface finish and tool steel properties unmatched in the metal 3D printing industry. Mantle’s 3D printer is built on a trusted CNC platform and utilizes multiple cutting mills to refine the shape of the printed tool while it is still in a soft state. The new High-Precision Shaping package enables tool rooms to produce tools with radii under 0.003", a 70% improvement compared to the .010" radii previously attainable, thereby eliminating more of the costly and time-consuming EDM operations of traditional toolmaking.

“Mantle allows us to offer production-grade tooling to our customers in prototype time,” says Eric Derner, technical sales applications engineer at Nicolet Plastics, an injection molder. “Mantle will allow us to reduce our need for offshore tooling, which introduces scheduling and supply chain risk, with comparable pricing. With Mantle’s H13 tool steel and new High-Precision Shaping capabilities, we can print tools in-house and deliver complex molded parts to our customers weeks faster than before.”

-

Watch this video about Mantle’s 3D printing technology which enabled moldmaker Westminster Tool to go from design to injection-molded prototype medical parts in three weeks.

-

Learn how Mantle’s P-200 printer and F-200 furnace metal 3D printing technology for toolmaking are said to simplify the way mold tool components are made and accelerate how manufacturers make molded parts, speeding the process of going from product idea to launch.

-

This video shows how PepsiCo used Mantle’s Hybrid 3D printing process to make blow molds for bottles.

- A recent webinar explored Nicolet Plastics’ success using Trueshape Technology to print injection mold tooling, as this method effectively reduced lead times and cost constraints, while producing better inserts.

Related Content

Nicolet Plastics Succeeds Using Mantle's Hybrid Metal 3D Printing Method for Mold Tooling

A recent webinar explores Nicolet Plastics’ success using Trueshape Technology, Mantle’s approach to print injection mold tooling. The current challenges this technology addresses and alleviates in additive manufacturing confirms this method is effectively reducing lead times and cost constraints, while producing better inserts.

Read MoreHybrid Manufacturing Turns Design Inside Out

Hybrid systems combine traditional subtractive processes with additional processes, including laser metal deposition for additive manufacturing and friction stir welding, enabling manufacturers to design products from the inside-out.

Read MoreWorld’s Largest Metal 3D Printer Seen at Ingersoll Grand Opening Event

Maker of large additive and subtractive machines adds capacity in Rockford, Illinois.

Read MoreHow 3D Printing Will Change Composites Manufacturing

A Q&A with the editor-in-chief of CompositesWorld explores tooling, continuous fiber, hybrid processes, and the opportunities for smaller and more intricate composite parts.

Read MoreRead Next

4 Ways the Education and Training Challenge Is Different for Additive Manufacturing

The advance of additive manufacturing means we need more professionals educated in AM technology.

Read More3D Printing Brings Sustainability, Accessibility to Glass Manufacturing

Australian startup Maple Glass Printing has developed a process for extruding glass into artwork, lab implements and architectural elements. Along the way, the company has also found more efficient ways of recycling this material.

Read MoreAt General Atomics, Do Unmanned Aerial Systems Reveal the Future of Aircraft Manufacturing?

The maker of the Predator and SkyGuardian remote aircraft can implement additive manufacturing more rapidly and widely than the makers of other types of planes. The role of 3D printing in current and future UAS components hints at how far AM can go to save cost and time in aircraft production and design.

Read More

.png;maxWidth=300;quality=90)