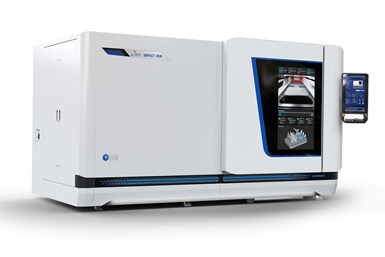

IRPD Impact 4530 for Metal Additive Manufacturing

The laser bed powder fusion machine features a modular, scalable design and is said to offer a high degree of automation and repeatability.

Share

Read Next

Photo Credit: IRPD

IRPD, a United Grinding brand, has developed the Impact 4530 additive printer for the production of metallic components in 3D printing. This laser bed powder fusion (LBPF) machine features a modular, scalable design and is said to offer a high degree of automation and repeatability, while designed for safe operation in industrial conditions.

The printer features a separate service and loading area, with an automatic system for changing containers for metal powder and components to ensure greater productivity, the company says. It is said the cleaning and maintenance of the system is also easy and uncomplicated due to its design, which is said to greatly simplify machine handling and increase productivity.

The company says the printing process is sustainable and resource-saving due to a closed, inert process cycle using construction containers. It is also said high repeat accuracy is achieved through the use of smart software due to its CORE OS technology. The hardware and software architecture is said to enable intuitive operation, networking with other machine tools and preparing for production largely independently.

The company says the printer is highly productive with up to 4 lasers of 1,000 W each thanks to a multibeam strategy, full-field optics and minimum nonproductive times "job to job" due to fast, automatic container and material changes.

Related Content

-

AM 101: What Is Binder Jetting? (Includes Video)

Binder jetting requires no support structures, is accurate and repeatable, and is said to eliminate dimensional distortion problems common in some high-heat 3D technologies. Here is a look at how binder jetting works and its benefits for additive manufacturing.

-

3D Printing Molds With Metal Paste: The Mantle Process Explained (Video)

Metal paste is the starting point for a process using 3D printing, CNC shaping and sintering to deliver precise H13 or P20 steel tooling for plastics injection molding. Peter Zelinski talks through the steps of the process in this video filmed with Mantle equipment.

-

Aluminum Gets Its Own Additive Manufacturing Process

Alloy Enterprises’ selective diffusion bonding process is specifically designed for high throughput production of aluminum parts, enabling additive manufacturing to compete with casting.

.png;maxWidth=300;quality=90)