Researchers Examine Additive-Subtractive Manufacturing Process Chain

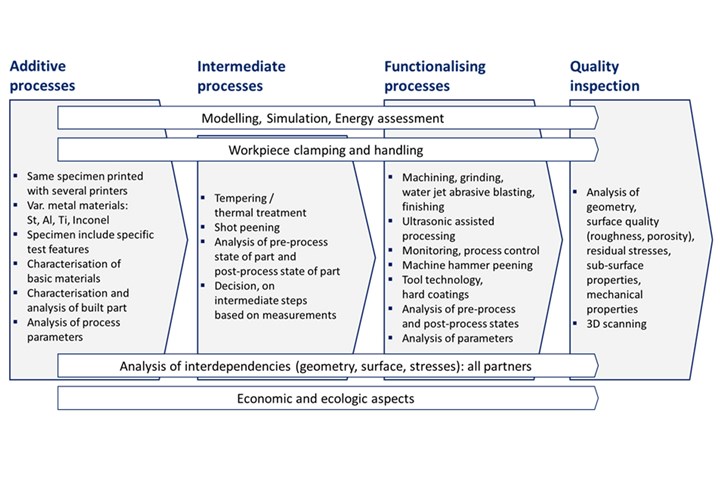

Researchers on the Advanced Processing of Additively Manufactured Parts project examined the additive-subtractive manufacturing process chain to optimize workpiece properties (such as geometry, surface and subsurface characteristics) throughout the entire process chain.

Share

Researchers working on the Advanced Processing of Additively Manufactured Parts (Ad-Proc-Add) project, accompanied by ecoplus Mechatronics-Cluster, have published their findings. The researchers systematically investigated additive-subtractive manufacturing (ASM) process chains, delving into the effects of various parameters, strategies and constraints on material and workpiece characteristics of additively produced components.

The project was carried out by nine research institutions from Germany, Austria, Belgium and Switzerland, and supported by a user committee comprising small and medium-sized enterprises (SMEs) from all pertinent market sectors. The project aimed to optimize workpiece properties (such as geometry, surface and subsurface characteristics) throughout the entire ASM process chain. The goal was pursued to precisely meet the diverse requirements of various industrial sectors.

The Forschungskuratorium Maschinenbau e.V. (FKM) coordinated the project, with the Institute for Machine Tools (IfW) at the University of Stuttgart overseeing the technical aspects. An international research consortium was established, bringing together essential expertise in additive manufacturing (AM), machining processes, process monitoring and control, machinery and systems, simulation and optimization, as well as energy efficiency analysis. Utilizing interdisciplinary expertise, detailed experimental studies were conducted to investigate the relationship between parameter settings and their impact on workpiece properties during additive and subtractive processes. These studies yielded valuable insights into physical effects and methods for process monitoring and quality control through correlation analysis.

Based on these findings, researchers developed new tool concepts, strategies for 3D printing metal components, sophisticated postprocessing methods, system prototypes for monitoring devices and additional services, all compiled in a digital compendium.

“Due to the exceptional collaboration with our industrial partners and under the excellent guidance of FKM and IfW, we not only achieved the ambitious goals of the research project but also produced industrially relevant and applicable results,” says Benjamin Losert, ecoplus project manager of the Mechatronics-Cluster.

The knowledge acquired aids system and service providers in developing new products with enhanced functionalities, while empowering end users to implement ASM process chains with greater productivity and improved economic and ecological efficiency. The digital compendium is available for free download from the Ad-Proc-Add project website.

- Read how Keselowski Advanced Manufacturing integrates CNC Machining with additive manufacturing.

- This article from AMT details how hybrid systems combine traditional subtractive processes with additional processes — including laser metal deposition for additive manufacturing and friction stir welding — enabling manufacturers to design products from the inside-out.

- This contributed piece from Pennsylvania State University asserts that the mindset for additive flips subtractive thinking inside out.

Related Content

-

3D Printing with Plastic Pellets – What You Need to Know

A few 3D printers today are capable of working directly with resin pellets for feedstock. That brings extreme flexibility in material options, but also requires greater knowledge of how to best process any given resin. Here’s how FGF machine maker JuggerBot 3D addresses both the printing technology and the process know-how.

-

What Does Additive Manufacturing Readiness Look Like?

The promise of distributed manufacturing is alluring, but to get there AM first needs to master scale production. GKN Additive’s Michigan facility illustrates what the journey might look like.

-

Additive Manufacturing Is Subtractive, Too: How CNC Machining Integrates With AM (Includes Video)

For Keselowski Advanced Manufacturing, succeeding with laser powder bed fusion as a production process means developing a machine shop that is responsive to, and moves at the pacing of, metal 3D printing.

.png;maxWidth=300;quality=90)