Kimya Releases Life Cycle Analysis Results for 3D filaments

Analysis results indicate that using Kimya’s recycled PETG filaments helps reduce CO2 emissions by 35% compared with standard PETG, which the company hopes will encourage users to give priority to recycled filaments in the interests of sustainability and resource conservation.

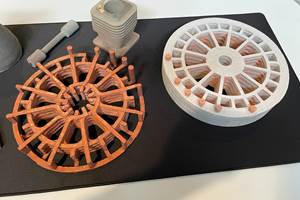

Kimya, Armor Group’s additive brand, continues expanding its range of recycled 3D filaments to turn waste into a genuine resource. Photo Credit: Kimya

In order to provide users with even more transparency, Kimya, an Armor Group company, recently published the Life Cycle Analysis (LCA) results for its 3D PETG filaments. The analysis concluded that using Kimya’s recycled PETG filaments helps to reduce CO2 emissions by 35% compared with standard PETG.

As a provider of eco-designed 3D materials, Kimya says it hopes to encourage users to give priority to recycled filaments in the interests of sustainability and resource conservation.The LCA is a multistage, multicriteria analysis that measures the environmental impacts generated by a product or service throughout its life cycle — from the extraction of raw materials to the end of life, including manufacturing and use.

Conducted in collaboration with Greenly and based on ADEME guidelines, the LCA of Kimya’s recycled PETG 3D filament shows an emission of 4.08 kg CO2 versus 6.27 kg CO2 for Kimya standard PETG filament. Using recycled filament helps to reduce emissions by 35% when compared with the standard version.

“Born out of our company’s DNA and a strong demand from our distributors, the Life Cycle Analysis, carried out on our standard and recycled PETG filaments, makes it possible to provide users with transparent information on the environmental impact of the materials they use, in order to encourage them to choose more environmentally friendly alternatives,” says Benoît Stoeux, Kimya managing director.

The company says its LCA approach is part of its ongoing commitment to more sustainable production. This include its “Remake” line of recycled filaments that it is continuing to expand. “At the same time, we are also thinking about our packaging, which is now 100% environmentally friendly, using recycled cardboard and soluble ink,” Stoeux says. “Not to mention the mounting flanges for our 3D filament spools, which are now made of 95% recycled polycarbonate. The next step for KIMYA is to conduct a full carbon assessment of our business in orderto accurately quantify ourcarbon footprint and undertake specific measuresto reduce our CO2 emissions.”

Kimya says the impetus is to produce fairly, without wasting resources thanks to 3D printing. According to Sculpteo’s “The State of 3D Printing” 2022 edition, additive manufacturing (AM) improves the environmental impact of activities of the users who were interviewed (managers, engineers, designers); 41% say AM helps companies meet their sustainability goals, and 61% of manufacturers believe the technology enables them to produce in the right quantities for their needs.

“Born out of the determination of the Armor Group to turn waste into a genuine resource, Kimya entered the additive manufacturing market in 2016 by offering its first filament designed using industrial waste from food packaging,” Stoeux adds. “At Kimya, we are convinced that 3D printing is a technology that can produce as close as possible to customer needs, without wasting resources.”

- Listen to this episode of AM Radio to hear how Kimya and Armor Group look to 3D printing to help close the loop for Armor’s circular economy with manufacturing 3D printing filament to recycle its own reclaimed plastic waste.

- Learn how Kimya is working to expand its range of recycled high-performance 3D Filaments, with researchers targeting between 70% and 100% recycled materials in so-called high-performance filaments, without affecting the properties.

- On this episode of AM Radio, listen to AM editors discuss Stratasys materials collaborations with Kimya and more.

Related Content

Concept Sneaker Boasts One-Piece 3D Printed TPU Construction

The Reebok x Botter Concept Sneaker Engineered by HP premiered at Paris Fashion Week, hinting at manufacturing possibilities for the future of footwear.

Read MoreReusable LOX/Kerosene Engine Completes First Successful Full-System Test Flight

Galactic Energy Space Technology announced the first successful full-system test flight of its Welkin 50-ton reusable LOX/kerosene engine. To date, this is the highest thrust LOX/kerosene engine in the Chinese commercial aerospace playing field which has officially entered the engineering and manufacturing phase.

Read MoreMultimaterial 3D Printing with Conventional Powder Metallurgy

Unbound sand serves as temporary, reusable molds for metal powders in Grid Logic’s 3D printing process.

Read MoreGE Additive Helps Build Large Metal 3D Printed Aerospace Part

The research is part of an initiative to develop more fuel-efficient air transport technologies as well as a strong, globally competitive aeronautical industry supply chain in Europe.

Read MoreRead Next

3D Printing Brings Sustainability, Accessibility to Glass Manufacturing

Australian startup Maple Glass Printing has developed a process for extruding glass into artwork, lab implements and architectural elements. Along the way, the company has also found more efficient ways of recycling this material.

Read MoreLooking to Secure the Supply Chain for Castings? Don't Overlook 3D Printed Sand Cores and Molds

Concerns about casting lead times and costs have many OEMs looking to 3D print parts directly in metal. But don’t overlook the advantages of 3D printed sand cores and molds applied for conventional metal casting, says Humtown leader.

Read MoreGE Additive Rebrands as Colibrium Additive

As part of the brand name transition, both the Concept Laser and Arcam EBM legacy brands will be retired.

Read More

.png;maxWidth=300;quality=90)